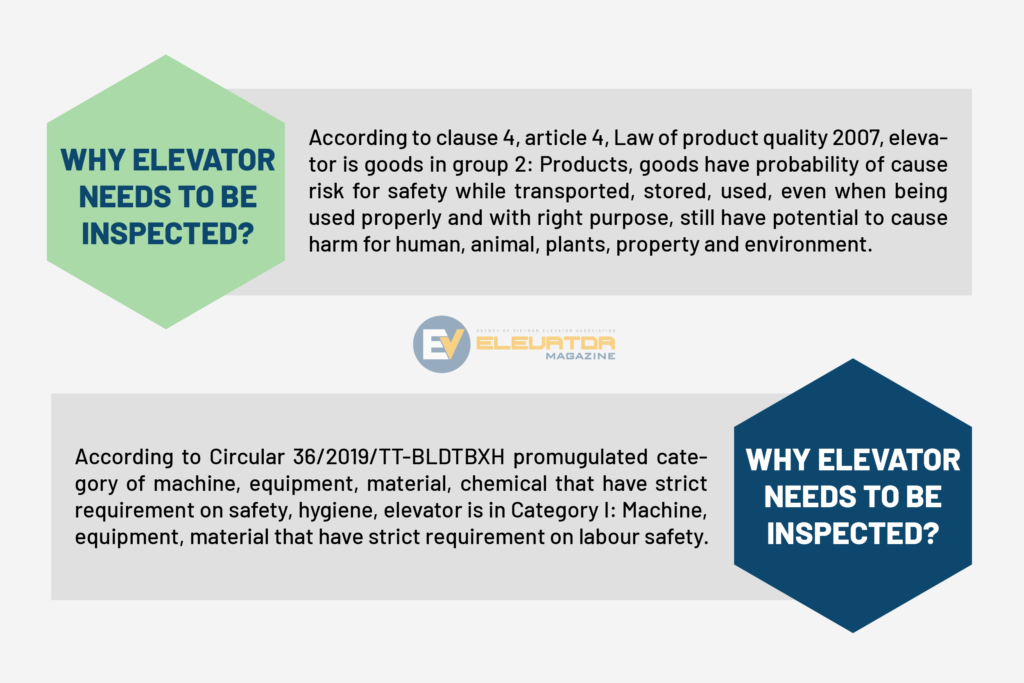

Home elevators have gradually become popular in social life. But perhaps not many people are aware that this is an item on the list of potentially unsafe products and goods. And customer need to be attentive to how to inspect, what needs to be noted to protect themselves and their family members.

Why elevator need to be inspected?

Accordingly, elevators, whether imported or manufactured, also need to strictly meet the requirements of technical regulations as well as inspection, maintenance and repair work in accordance with regulations.

In addition to regulatory compliance, elevator inspection also benefits consumers themselves – not everyone has the technical expertise to be able to determine the condition of a product, especially with elevator, a product with high technical characteristics. Technical inspection of elevator safety is carried out by an independent unit for the first time and periodically for subsequent times. These experts will assess on behalf of consumers:

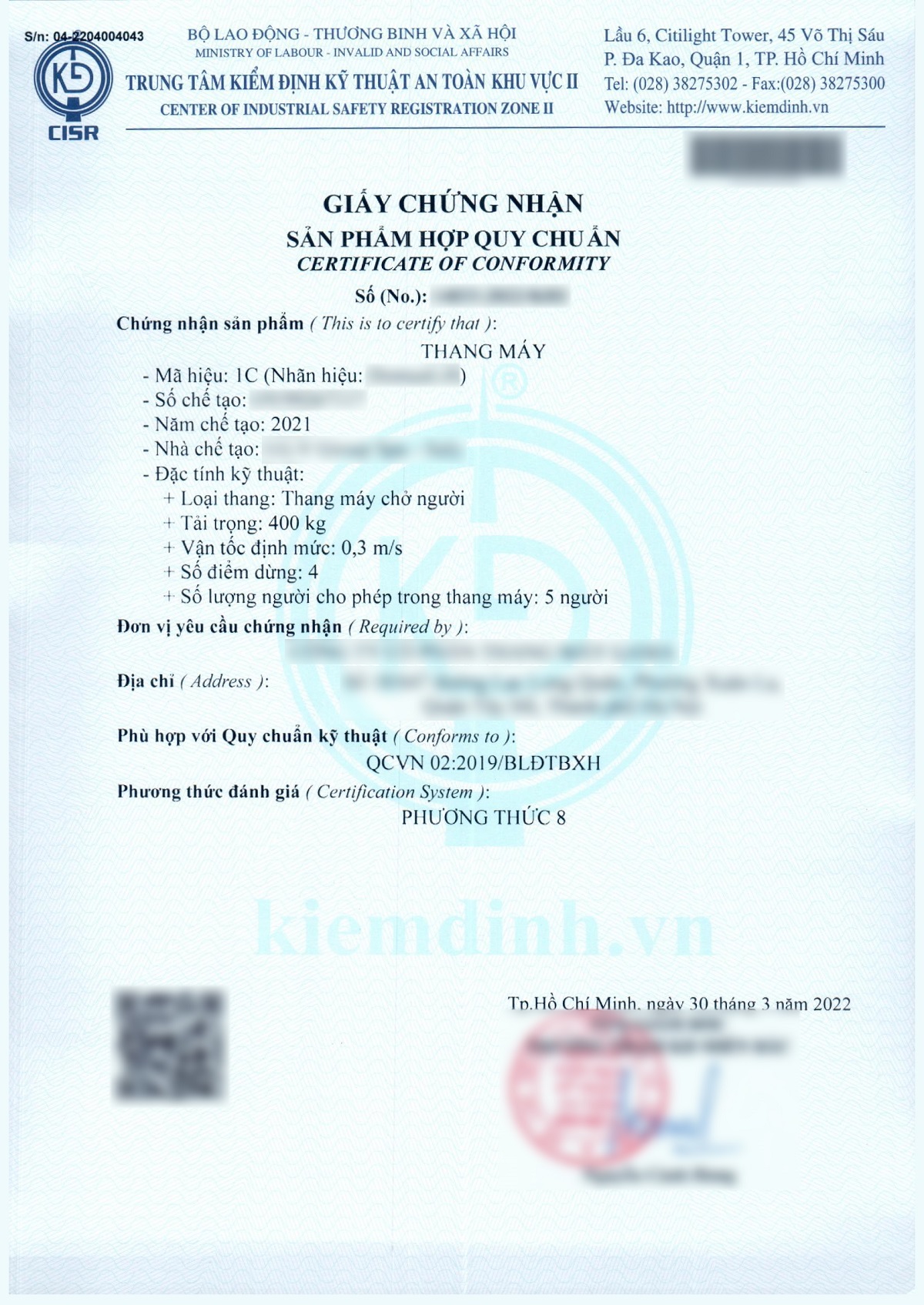

– Profile, history of elevator. In fact, many businesses have taken advantage of consumers’ ignorance to fake elevator profile, most commonly certifying elevator conformity – a mandatory procedure for products to be circulated in the market.

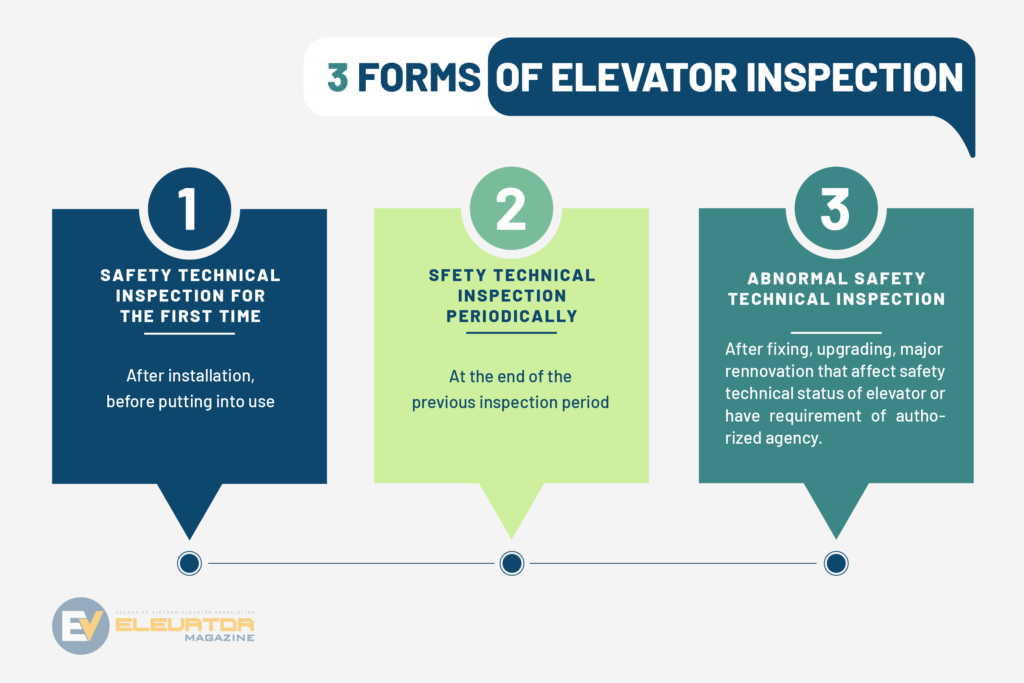

– Quality inspection of equipment after the process of installation and operation (first inspection); assess the current state of equipment quality during use (periodic inspection, abnormal inspection)

– Find out the reasons why the elevator does not ensure technical safety, propose solutions to overcome.

From there, it is possible to ensure the safety of the user, ensure the quality and efficiency of the elevator, predict technical problems for maintenance and repair if necessary to prolong the life of the elevator.

Technical inspection of elevator safety is completely aimed at the benefit of consumers. It is the “technical barrier” to help protect consumers in the process of buying and selling, using with businesses providing elevator products and services.

Basic things to know about elevator inspection

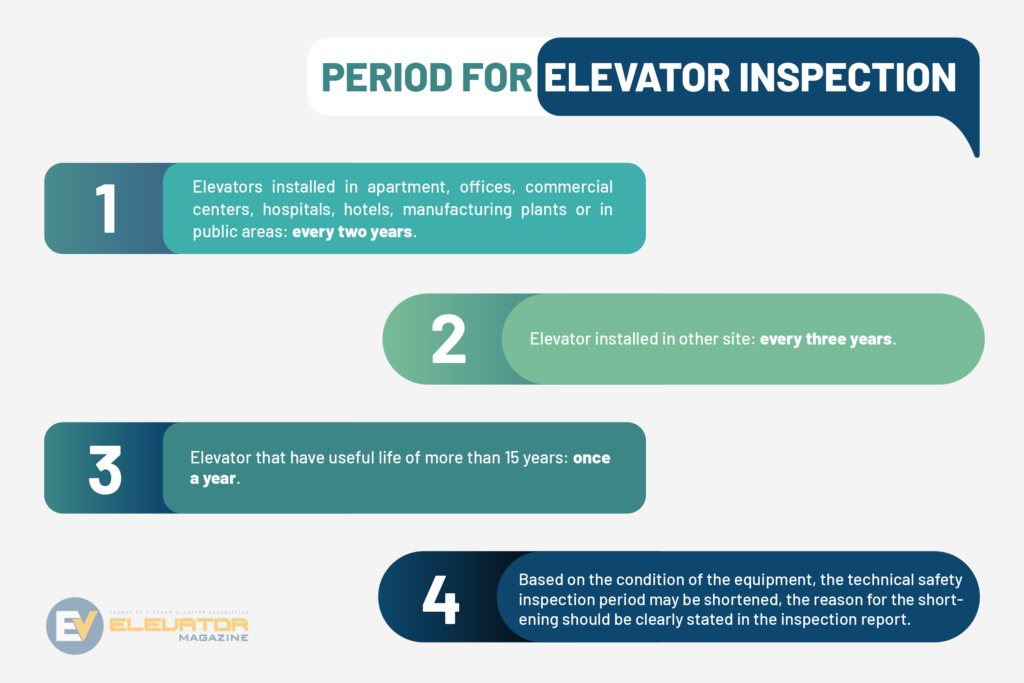

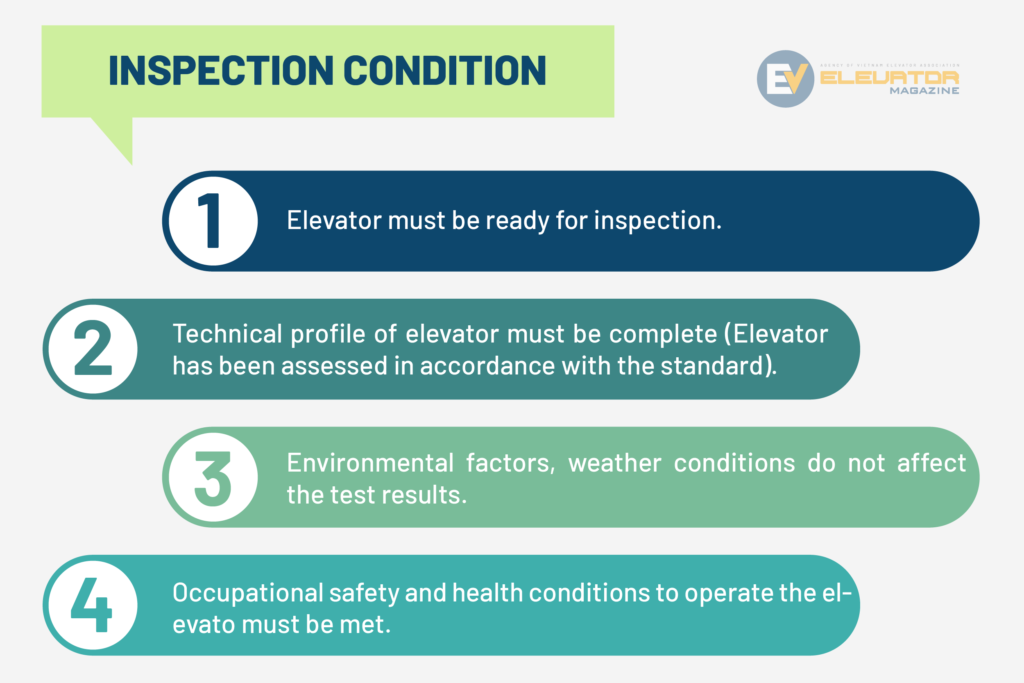

Elevator safety technical inspection (hereinafter referred to as elevator inspection for short) is an activity to assess the technical condition of elevator safety according to national technical regulations and safety technical standards before being put into use. After the inspection, if the elevator operates normally and meets the safety standards, it will be stamped with an inspection stamp. This is one of the activities that must be performed with elevator products to ensure occupational safety and health.

In addition, the person responsible for the inspection of the elevator is the organization or individual that manages, uses and owns the elevator.

In which, in condition 2, the elevator that is assessed to be in compliance with the standard will be confirmed through a certificate of conformity as shown below:

Notes when inspecting elevators

Elevator inspection unit:

Those are the units that are granted the Certificate of eligibility for technical safety inspection by the State. For example:

– Units licensed by the Department of Occupational Safety, Ministry of Labor, War Invalids and Social Affairs: Area I Safety Technical Accreditation Center; Regional Center for Safety Technical Accreditation II; Technical inspection JSC, safety and Construction Consultation; Inspection and Safety Occupation Training Center in HCMC and some social enterprises.

– Military Safety Technical Accreditation Center under the Ministry of National Defense.

– Industrial Accreditation Center I; Industrial Accreditation Center II; Industrial Testing Center III of the Department of Industrial Safety and Environment Engineering under the Ministry of Industry and Trade.

Test preparation:

– The inspection organization and the establishment requesting the inspection shall cooperate together: Agree on the inspection plan, prepare the conditions for testing and appoint people to participate and witness the inspection.

– Establishment requesting inspection: Prepare documents, resumes and documents related to the elevator.

– The inspection organization and the establishment requesting the inspection shall cooperate: Agree on the implementation of safety measures; Fully equipped with tools and personal protective equipment, ensuring safety during the inspection.

Profile, history of elevator:

– Elevator history

– Certificate of conformity (in case of first inspection)

– Certificate of inspection, inspection record has been issued (no inspection for first-time inspection)

– Maintenance records

– Records of maintenance, repair and replacement (if any)

– Dossier of design, construction completion of elevator shaft (inspection for elevator installed, first inspection)

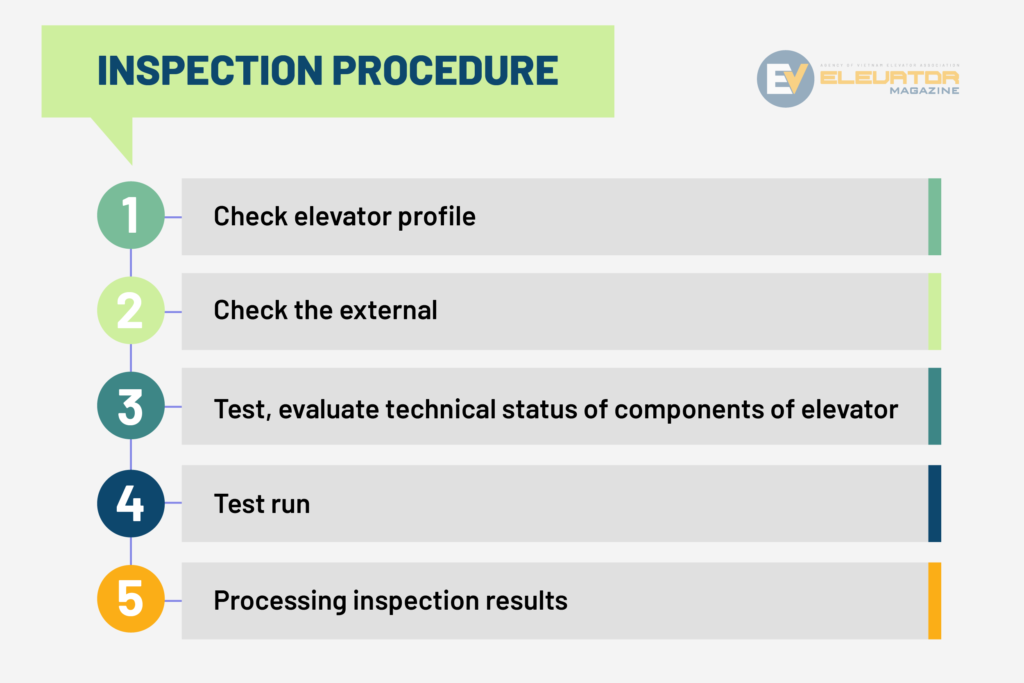

Processing test results:

a) Make an inspection record with all contents according to the form prescribed by the Ministry of Labor, War Invalids and Social Affairs.

b) Approving the inspection record

c) Write a summary of the inspection results in the elevator’s resume (specify the full name of the inspector, date of inspection).

d) Enter the inspection results into the database to print the inspection stamp and the Certificate of inspection results (if any).

e) Stamping of inspection: When the elevator inspection results meet the technical safety requirements, the inspector affixes the inspection stamp to the equipment. Inspection stamps must be affixed in an easy-to-observe position.

f) Issuance of the certificate of inspection results:

– When the elevator has inspection results that meet safety technical requirements, the inspection organization shall issue a certificate of inspection results for the elevator within 05 working days from the date of approval of the inspection report at the facility. department.

– When the elevator has inspection results that do not meet the requirements, only the steps mentioned in points a and b above must be followed, which must clearly state the reason for the elevator failing to meet the inspection requirements, and propose the establishment, remedial action and time limit for implementation of such recommendations; at the same time send the inspection record and notify the local labor state management agency where the elevator is installed and used.

Sanctions for handling violations of not inspecting elevators:

Article 23, Decree 28/2020/ND-CP stipulating penalties for administrative violations in the field of labor, social insurance, sending Vietnamese workers to work abroad under contracts (effective force from April 15, 2020) for elevators that are equipment with strict requirements for equipment inspection: Fine from 2 to 3 times the total cost of inspecting violating machines, equipment and materials (calculated according to the level of violation). the minimum price set by the competent authority) but not less than 20,000,000 VND and not more than 75,000,000 VND for the act of failing to inspect before putting into use or not periodically inspecting during the process of using machines, equipment and materials with strict requirements on occupational safety.

In addition to sanctions for violations when not performing elevator inspection activities as prescribed, failure to inspect elevators also puts consumers at risk with elevator suppliers falsifying elevator records and machines such as CO, CQ, certificate of conformity, etc.

At the same time, the process of using the elevator with warranty and maintenance units does not ensure technical safety, the inspection unit will actually perform the function of becoming a “technical barrier” for consumers to use.

Therefore, elevator owners and elevator operators need to strictly comply with the regulations on elevator inspection, both complying with the law, and ensuring their rights.