1) Waterproofing Elevator Pits

To avert damage from water seepage into elevator pits, preventive measures must be implemented right from the construction stage. Elevator pits are typically constructed in two primary methods: monolithic poured concrete—involving excavation followed by pouring to create a smooth surface; or brickwork—resembling conventional brick wall structures. Over time, both types can develop cracks or gaps, facilitating water infiltration into the installation.

To block water entry, various waterproofing techniques can be employed, such as bentonite membranes, penetrating sprays, or waterstop installations along the pit walls, forming an external barrier layer. Should cracks emerge, polyurethane grout can be injected to seal them, followed by concrete patching.

Elevator pits are often positioned below natural ground level, rendering them highly vulnerable to groundwater seepage or flooding from storms and heavy rains.

Additionally, during construction, it's essential to heed section 2.2.7 of QCVN 02:2019/BLĐTBXH, which mandates: "... The area in front of the landing door threshold must be sloped outward to prevent water from cleaning operations or sprinkler systems from entering the car."

2) Protecting Components and Equipment from Water and Rust

While QCVN 02/2019 on elevators does not mandate water resistance ratings for electrical devices, for installations in flood-prone areas, minimizing risks requires all pit-bottom equipment to be certified with at least IP67 water protection, shielding the system from severe damage. At the first sign of water ingress from floors, ceilings, or vents, immediately disconnect power, shut down the elevator, isolate the battery, and trip the main breaker to ensure safety.

Beyond abrupt water intrusion, persistent seepage leading to prolonged pit flooding without remediation—or recurrent dampness (from humid weather)—can dramatically elevate shaft humidity, impacting the entire system.

In regions susceptible to frequent flooding, comprehensive flood prevention strategies for elevators are imperative. In the photo: Mechanical components severely rusted, compromising the elevator's safety structure.

Thus, for elevators in high-humidity environments, stainless steel materials must meet grade 304 or equivalent standards, with landing door contacts and safety devices rated IPX6 or higher. If complete prevention of water or humidity ingress proves impossible, apply anti-rust coatings to supports and welds, utilize IPX6-rated or higher lighting, and enclose circuit boards and wiring in sealed boxes to avoid direct water exposure, thereby extending equipment longevity.

3) Installing Pit Drainage Pumps

During elevator pit construction, incorporate a dedicated drainage system or sump with a pump exclusively for the shaft, avoiding sharing with other facilities. This setup channels water to a centralized point, thereby reducing damage to pit equipment and components.

Illustration of a sump and submersible pump system.

For draining pit water, employ submersible sump pumps, typically housed in an adjacent sump pit. Even with waterproofed walls, leaks can occur through cracks, pipes, or condensation, making timely pumping essential to prevent accumulation and rising levels.

This system collects and discharges water to a drainage zone or separate sewer. Installation should involve expert consultation and adherence to prevailing building codes and standards.

Drainage or sump systems with submersible pumps are routinely applied to firefighting and evacuation elevators. The U.S. ASME standard specifies: For elevators with firefighting functions, install drainage or submersible pumps with a minimum capacity of 3,000 gallons per hour per elevator (equivalent to approximately 11,400 liters per hour, or 190 liters per minute).

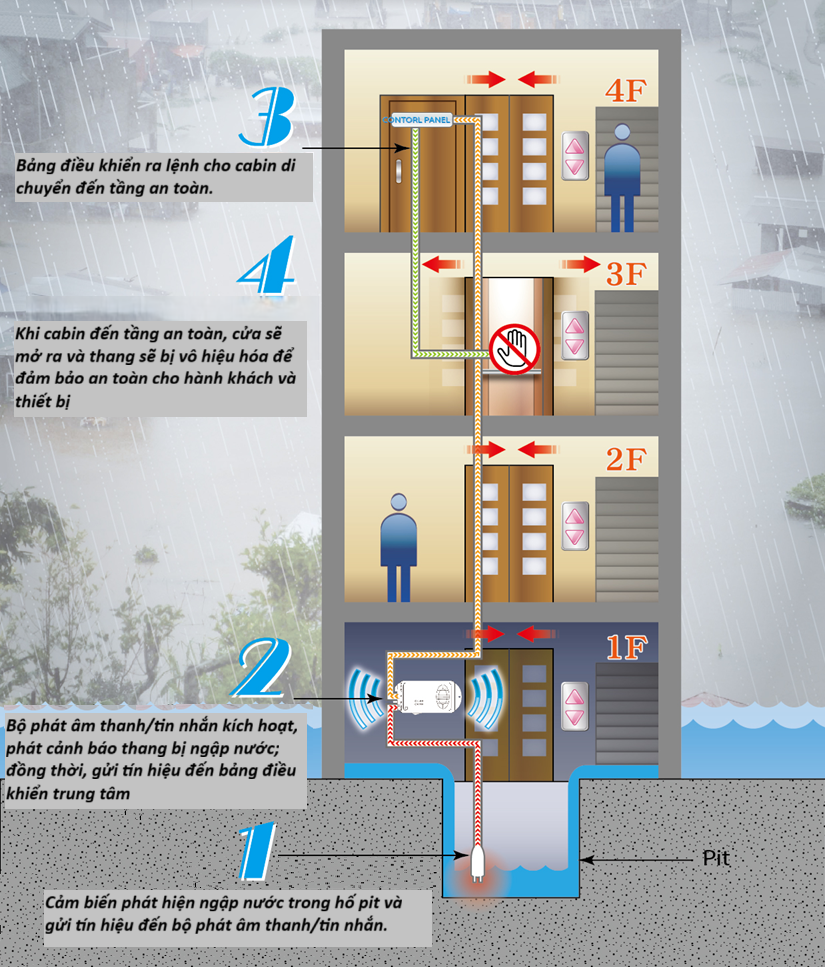

4) Installing Elevator Flood Warning Systems

Amid escalating occurrences of heavy rains, high tides, or flooding, equipping elevators with automatic flood warning systems is crucial for safeguarding people and equipment.

The shaft flood warning system relies on water level sensors (or electronic floats) positioned at the pit base. Upon water rising to the sensor threshold, a signal is promptly transmitted to the elevator's central controller.

Illustration of elevator pit flood sensor operation.

The controller then autonomously engages protection mode: relocating the car to a secure intermediate floor, opening doors for passenger egress, and subsequently deactivating the elevator to mitigate risks of short circuits or equipment failure.

In sophisticated systems, alerts are also dispatched to technical personnel or building monitoring centers, facilitating rapid deployment of remedial actions to avert deep flooding and system impairment.

5) Installing Elevator Flood Barriers

Flood barriers represent mechanical safeguards installed at elevator landing doors vulnerable to flooding during storms (basements, ground floors, doors with balcony access, etc.), designed to prevent water intrusion into the shaft amid heavy rains, high tides, or localized inundation. Constructed from aluminum alloys or stainless steel, these systems withstand high water pressure and resist corrosion.

When flood risks materialize, barriers are manually erected or automatically activated to form a sealed perimeter around the door and exterior space, halting water flow into the shaft. Once waters recede, barriers can be readily dismantled or retracted, restoring normal elevator functionality.

Tailored to building specifics and local flood alert levels, options include:

- Demountable flood barriers: Crafted from lightweight aluminum or steel, swiftly installable by one or two individuals upon heavy rain warnings. Secured with water-sealing gaskets, they block seepage through landing door gaps or shaft entrances. Ideal for basements or ground floors facing mild to moderate flood threats.

Partial flood barriers suited for lightly flood-prone areas or landing doors opening outdoors, susceptible to rainwater splash.

- Bulkhead flood barriers: Offering 100% watertight protection around the full door perimeter. Suitable for basements or ground floors at high risk of complete submersion.

Bulkhead barriers are apt for basement zones prone to total inundation.

Ultimately, the optimal approach to shield elevators from flooding hazards while prioritizing safety lies in proactive readiness—from design and construction through installation, maintenance, and operation. Prevention invariably proves more effective and economical than post-event recovery.

https://tapchithangmay.vn/quy-chuan-tieu-chuan-ve-chong-ngap-nuoc-cho-thang-may/

![[Photos] Impressions of Vietnam Elevator Expo 2025 [Photos] Impressions of Vietnam Elevator Expo 2025](https://media.tapchithangmay.vn/share/web/image/2026/1/mobi6703639038935945497270_350x210.webp)