Hyundai Elevator (South Korea) has completed the development and commercialization of modular elevator technology, marking the first deployment of this system in the country. This innovation not only enhances installation safety and minimizes accidents but also reduces construction time by 60-70%.

Amid South Korea's tightening of stricter penalties for workplace accidents, demand for modular elevator technology is expected to surge rapidly in the nation. Companies with recurring incidents now face fines up to 5% of operating profits and even license revocation, making safer alternatives like modular elevators increasingly appealing.

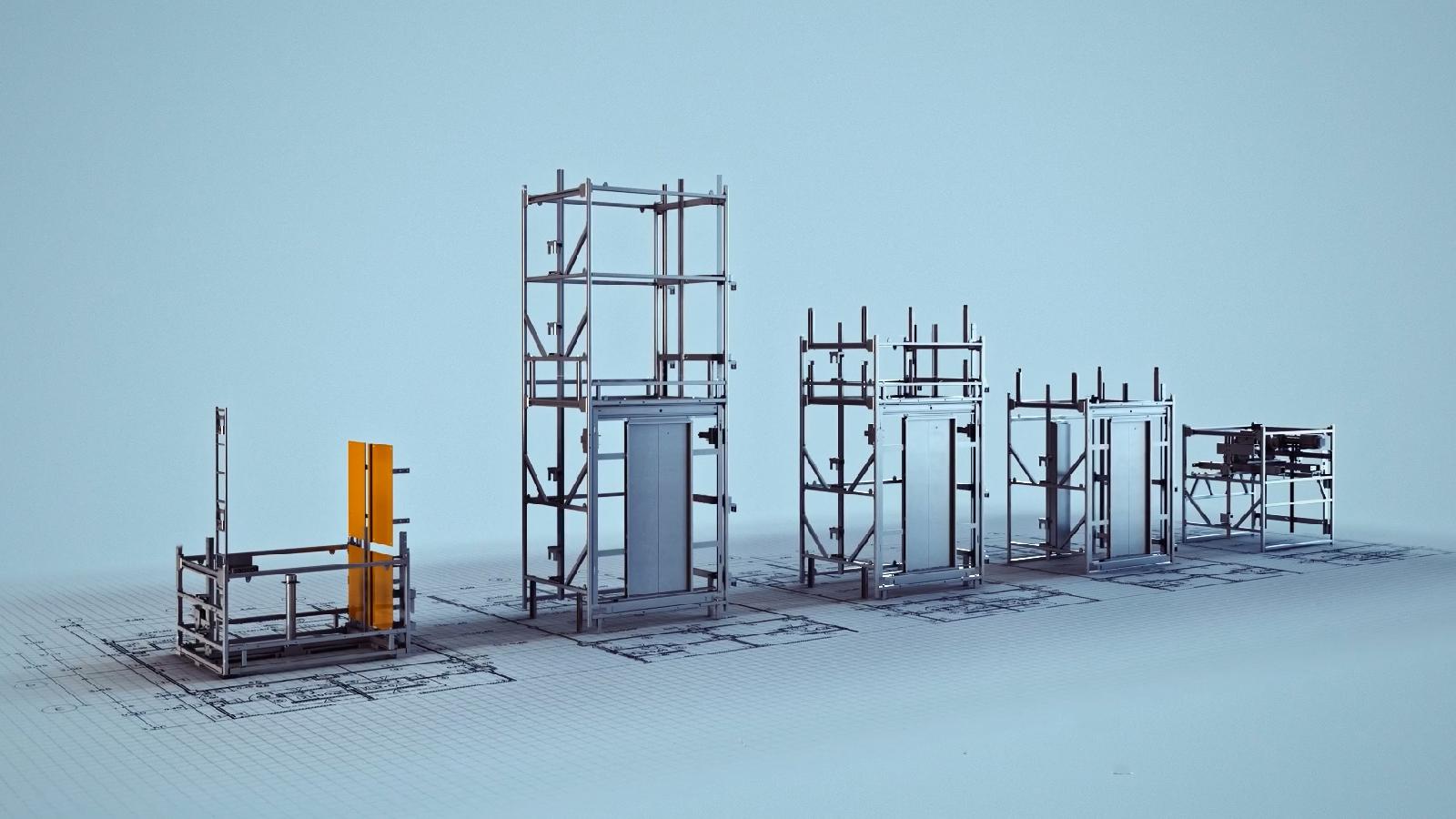

Simulation of modular elevator components developed by Hyundai Elevator

Sources also indicate that Hyundai Elevator is currently in discussions with several major South Korean construction conglomerates about applying this elevator technology to projects, accelerating the commercialization process.

Cho Jae-cheon, CEO of Hyundai Elevator, stated: “Modular elevators will become a new model for construction sites, helping us achieve our goal of zero serious accidents. We will expedite commercialization by actively proposing their use in large-scale residential and commercial projects in the future.”

Efficiency, Quality, and Market Prospects

Unlike traditional methods of installing elevators directly in the shaft, modular technology allows key components to be manufactured and assembled at the factory before being transported to the site as complete modular units.

The greatest advantage of modular elevator technology is its ability to minimize the risk of serious accidents by significantly reducing hazardous work inside the elevator shaft—the area considered the most dangerous during installation. Many complex and risky tasks, such as cabin installation, rail suspension, or landing door fitting, can be eliminated.

Construction time is also drastically shortened. For machine-room-less (MRL) elevators, the traditional 10-step installation process is reduced to just five steps. For instance, installing an elevator in a four-story building drops from about 45 days to 18 days. This allows subsequent tasks, like interior and exterior finishing, to begin earlier, shortening the overall project timeline.

According to Hyundai Elevator, elevators produced in a factory environment with stable temperature, humidity, and working conditions minimize quality deviations caused by on-site variables. On-site labor is projected to decrease by around 30%, helping address the ongoing labor shortage and reducing construction costs for the industry.

Hyundai Elevator engineers conducting modular elevator installation tests at the Hyundai Asan Tower in Icheon, Gyeonggi Province.

Hyundai Elevator has invested years in researching, developing, and testing this technology, viewing it as a key driver for future growth. According to the Gross Market Report, the global modular elevator market is projected to grow at an average annual rate of 7.2%, from $1.85 billion in 2024 to $3.47 billion by 2033.

Bae Sung-joon, Director of Modular Development at Hyundai Elevator, commented: “Modular elevators can simultaneously address seemingly conflicting challenges—meeting increasingly stringent safety requirements while shortening construction timelines. This will become a new turning point for the construction industry.”

https://tapchithangmay.vn/an-do-de-xuat-ap-thue-chong-ban-pha-gia-doi-voi-phu-tung-thang-may-trung-quoc/

![[Photos] Impressions of Vietnam Elevator Expo 2025 [Photos] Impressions of Vietnam Elevator Expo 2025](https://media.tapchithangmay.vn/share/web/image/2026/1/mobi6703639038935945497270_350x210.webp)