EM – “Through practical work, we aim for better, faster and more effective ways of doing things. In short, I call it professional trickery. Each job has its own tricks, each worker has his own trick.” That is the opinion of an automotive technician, as an affirmation that experience always gives an advantage to a technician. Is this true for the elevator maintenance profession?

Experience is an advantage?

A topic was raised and received a lot of comments, contributions as well as “looks” from the technical world: Do you have any professional tricks you want to share with people in the same profession?

For example, a small but powerful “device” such as a condom (which is a measure to reduce the risk of unwanted pregnancy in women and avoid the spread of STDs during sex) is also included in this group of tricks from personal experience.

However, experience is not always right. Although that experience can be effective at work, there are also “items” of experience that are used as a gimmick at work, with many potential dangers. Typically with the elevator profession, readers can refer to: Elevator craft tricks

And whether with the elevator maintenance profession, how does experience prevail and is there any opportunity for young inexperienced workers?

The nature of the elevator is a complex technical and high-tech equipment, which is constantly being upgraded. In Vietnam, elevators have been popular for more than 30 years, this time period also witnessed the rapid change of different elevator technologies. That means that in addition to the modern elevator lines produced recently, the elevator service industry also needs to take care of the maintenance and repair of the old elevators.

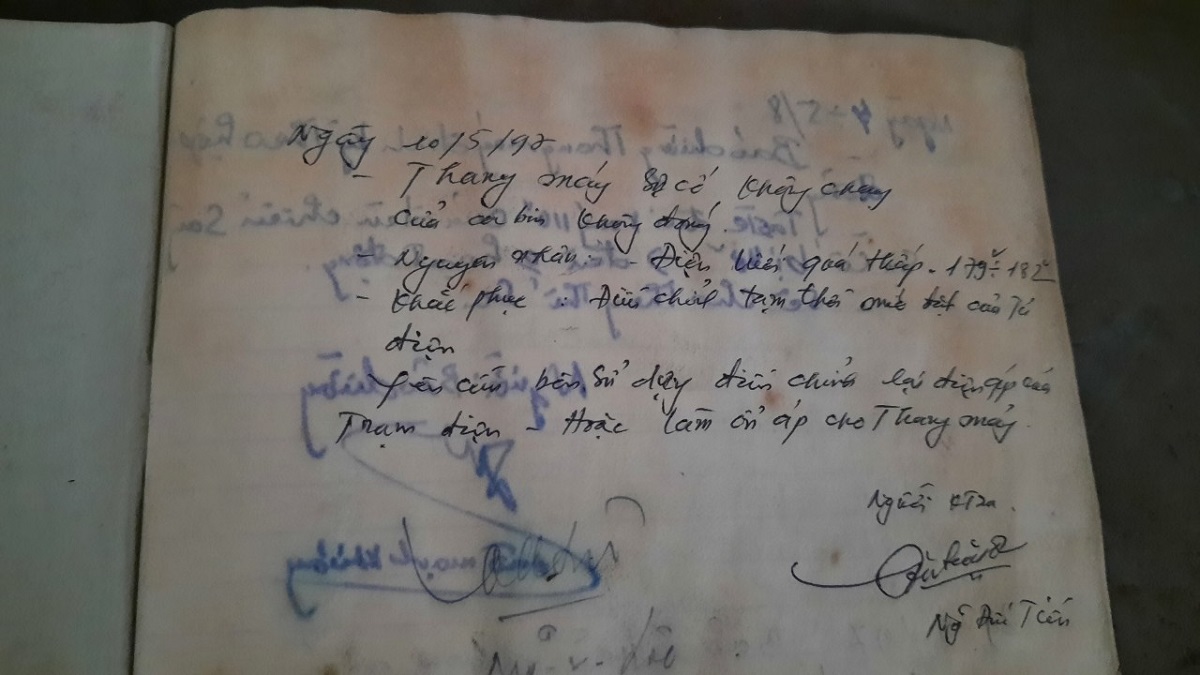

An elevator that was installed since 1996 and maintenance records starting from 1997, it’s been 25 years but this elevator is still in good working order thanks to full maintenance

In addition, the elevator market today is also diverse in products. It is from this fact that the units/technicians who succeed in maintaining the old elevators often face many difficulties in recognizing the status as well as the implementation techniques for each project.

Therefore, many people think that for elevator maintenance workers, experience is the advantage of workers.

This statement is also not completely wrong because this is likened to the profession of “the doctor of the elevator”. Experience allows the technician to have the ability to judge the situation, to have more effective prevention options for the “patient”. In addition, for old elevator works with outdated features and techniques that cannot be replaced, an experienced technician will also take over.

The electrical cabinet system of the elevator since 1996, many components are no longer on the market to replace, requiring experienced maintenance technicians to take care of them.

However, if the background knowledge is not correct, there are no standards on working methods and technical regulations, then experience brings the risk of more serious mistakes, which can directly affect the quality of product and the health and safety of elevator users. Only when we have benchmarked, experience will allow us to improve work more efficiently, improve quality better in a transparent and healthy way.

“Only when the root is strong, tree is strong”

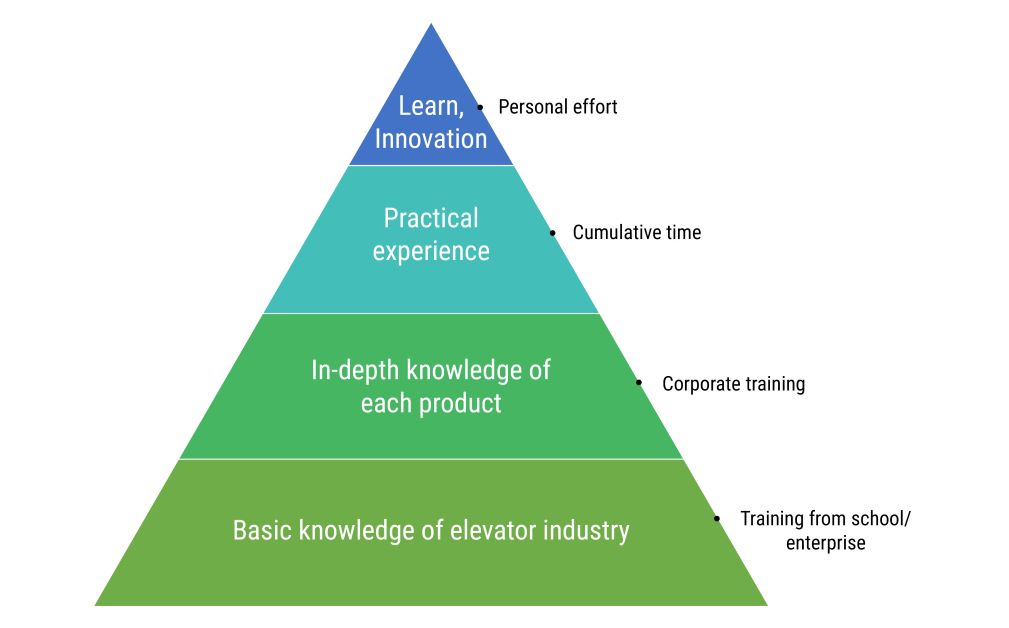

That philosophy is probably true for all fields, even for career development. Let’s take a look at the capacity tower below:

It can be affirmed that training is the core foundation issue. Only standard training from the ground up combined with accumulated experience can make a worker develop well. In addition, because techniques and technology are always in motion and innovation, periodic additional training to update knowledge and changes in technical regulations is also extremely important.

Practical experience and the ability to learn and renew knowledge all depend on the individual employees, which are values that are necessary but not mandatory. Knowing that human resources is always the core issue that determines the success or failure of every business, therefore, a solid foundation is the best springboard for businesses to build an elite staff. And that’s in the part of knowledge that can be trained.

Basic knowledge of the elevator industry includes: 1. Overview of elevators; 2. Electric tools in elevators; 3. Mechanical alignment; 4. Skill in using measuring equipment; and 5. Occupational safety. This knowledge can be acquired from school or similar technical fields.

In-depth knowledge of each product line will relate to control programs, mechanical design, specifications, components, equipment, advanced features, etc. This content will depend directly on products provided by enterprises, so workers need to be trained directly at enterprises.

Even senior technicians who move from one business to another still need to be re-trained in in-depth knowledge of each product line. Most elevator businesses usually only choose 1-2 elevator technology lines for production or distribution, which means that personnel only have specialized experience for these lines for maintenance and repair based on the products of the business I used to work for.

If businesses refuse to invest in training costs, just waiting for the self-efficacy of employees, it will be difficult to have a sustainable, knowledgeable team and build trust with customers.

Oppotunity and challenge

It is not that businesses do not want to invest, but the reluctance arises from the risk of wasting training costs and time. Many workers, after being trained and practicing relatively well, want to increase their income commensurate with their qualifications, but instead of proving their capacity and proposing their wishes, they “jump jobs”. In addition, is the freelance culture in Vietnam also popular, at the same time, the lack of practice regulations for freelance workers, the “comfort” of many customers makes many workers when If you are quite sure of your skills, you will choose to work as a freelancer, receive a contract directly from the elevator user instead of sticking with a business.

This is a difficult problem for businesses in building regimes to retain workers and avoid loss of initial investment costs.

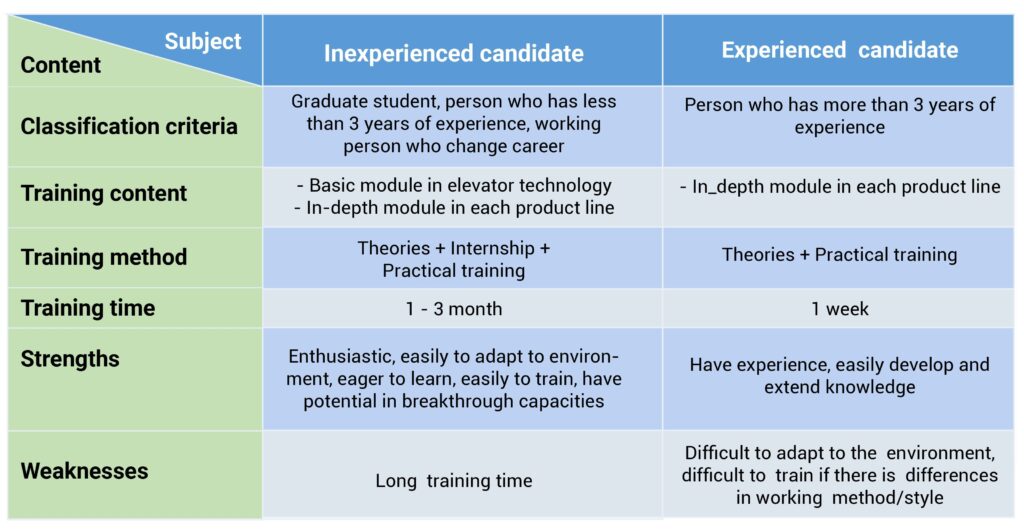

Sharing from a Technical Training Manager of an elevator service business, newly recruited employees are trained according to experience and knowledge:

From the comparison table, businesses can see a correlation between advantages and disadvantages for businesses to calculate investment costs compared to the results of personnel.

And then, employees are willing to learn a new field, along with a commitment to stick worthy of the training costs that the enterprise invests in.

There have been links between businesses and schools in training and recruitment towards students who have been practiced, thereby gaining certain practical experiences to meet the requirements of businesses. On the contrary, businesses also reduce investment costs in the process of training new personnel.

However, elevator technicians are not necessarily all from vocational training schools (intermediate, college, university) but also from high school or from other technical fields. Is there a need for training programs as a kind of practice certificate to create a commitment to the competence of employees? At that time, the opportunity for businesses and employees to have faith in each other will certainly be more grounded, and the risk of wasting investment from businesses will be significantly reduced.

This form also helps customers to sign maintenance contracts with freelancers based on the worker’s capacity, avoiding the situation of “spend money on a quack doctor and only get worse” when hiring incompetent workers.

The capacity of workers will no longer be “ignorant” if there is a standard training and testing program

Nguyen Minh