“Our country is still poor” is an excuse for us to accept low quality of products and services. By being easy, we cannot exit poor!

There is still gap in Pre-posted – Post-inspection?

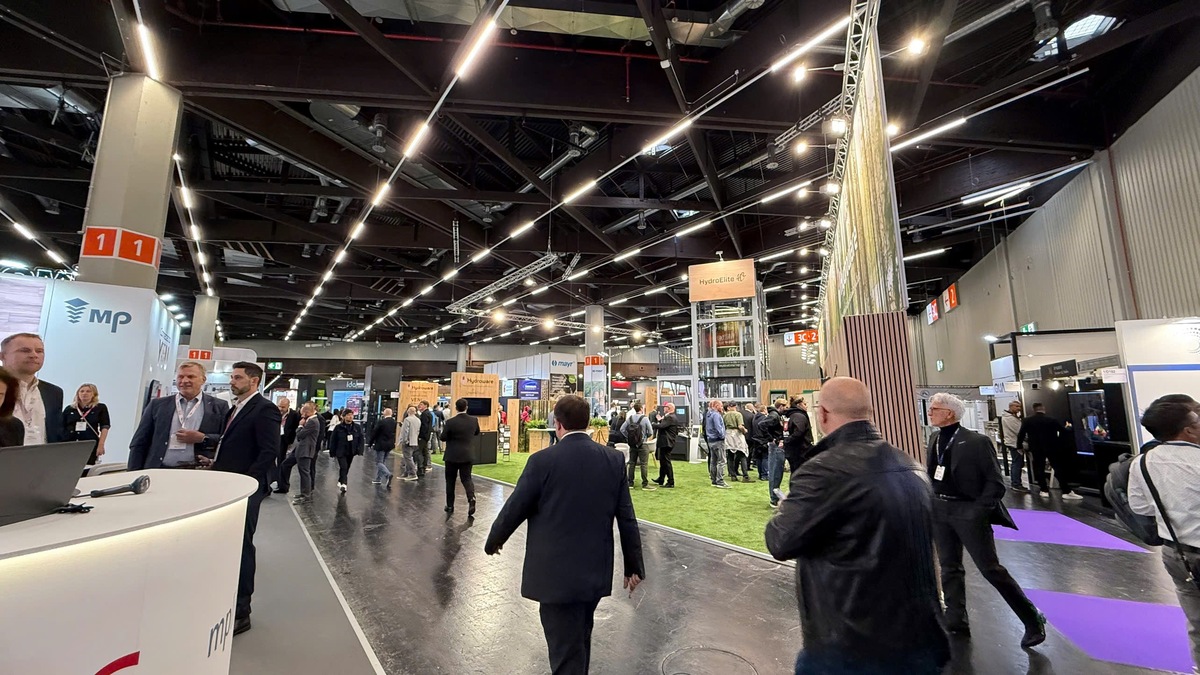

Mr. Nguyen Hoang Linh, Deputy General Director of the General Department of Standards, Metrology and Quality said that the work of applying the post-inspection regime to products and goods subject to specialized inspection falls under the management of the Ministry of Science and Technology helps businesses reduce time and costs. The General Department has cut about 96% of the number of goods shipments subject to pre-inspection; Reduce import quality inspection time from 23 days ago to 1 day. In 2020 alone, the inspection mechanism saves VND 832 billion for businesses in Vietnam.

This is a positive result from Post – inspection, saving money and time for businesses is also creating conditions for businesses to develop “wide road”. And towards the optimal solution for the development of such an enterprise, the management agencies also need to perfect the institutions and legal corridors on the quality of products and goods, standards, and standard technical processes, in that Research, propose Amending and supplementing the Law on Standards, Technical Regulations, the Law on Quality of Goods Production, etc.

Helmets have been transferred to post-customs clearance inspection – Source: VnExpress

However, even if the legal framework has been completed, post-inspection is still a mechanism by which businesses need to actively perceive the quality of their products instead of having an accurate measure in advance. It is also when consumers receive information directly from businesses without going through the “filter funnel” of the accuracy of the regulatory agency.

Acknowledging the undesirable consequences of this mechanism, we cannot ignore them without considering them as valuable lessons!

In December 2021, the whole country was shaken by the news that Viet A company had inflated the price of a COVID-19 test kit. Through the investigation back in time, there were many signs of wrongdoing of Viet A right from the early stage of conducting a scientific research project to produce test kits, but at the time of discovering the incident, the profits that This company’s gain has been huge. According to the initial testimony of Phan Quoc Viet (Chairman of the Board of Directors and General Director of Viet A Company), Viet had “shaken hands” with partners to raise the price of the test kit to about 45%, the amount of Viet A’s revenue in this case is over 500 billion VND; The amount of “commission” that Viet A spends on “partners” is nearly 800 billion VND.

Test kit product of Viet A Company – Source: The Laborer

The problem is not only in raising the price of the test kit, but this product is not even manufactured by the company itself according to the Scientific Project on the COVID-19 test kit product of the Ministry of Science and Technology, even though there is a temporary circulation registration license (According to Decision No. 774/QD-BYT dated March 4, 2020), an official circulation registration license (According to Decision No. 5071/QD-BYT dated December 4, 2020) at the Ministry of Health. The General Department of Customs announced that from September to December 2021, Viet A Company imported 3 million COVID-19 rapid tests from China with a total value of 64.68 billion VND, declared price 0.955 USD/test (about 21,56 thousand VND/test).

Thus, it can be seen that the violation at Viet A Company is a series of violations related to different state agencies and is based on the “pre-post – post-audit” mechanism that the role of controlling the origin, quality, production process, pricing, … of the authorities have not been implemented.

The main mode of state management in the direction of inspection and control is gradually being replaced by the main mode of cooperation and facilitation. “Pre-check mode” is gradually changed to “pre-post – post-check”. The effectiveness of state management over enterprises is increasingly being enhanced. This is considered the key to institutional reform and opening up the market economy. However, even if we mention the importance of eliminating such “Viet A variants”, it is clear that our post-audit mechanism still has gaps that need to be reviewed, overcome soon.

Establishment of non-tariff barriers is necessary

Each market has its own set of rules and standards as the rules of each playing field. Vietnam also has, but we have not established our own playing field!

We have been used to the concept of “rescuing agricultural products” for many years now, especially when the outbreak of the COVID-19 pandemic made trade between countries difficult. But we can’t save agricultural products forever, it’s time for agricultural products to save themselves.

While the Vietnamese market has a clear “xenophile” expression with imported fruit products, imported frozen foods, and imported technological equipment, these products are also our own looking to export to foreign countries. To export to any market, it is necessary to follow the rules of the game of that market. The main feature is the standards of foreign markets such as Japan, the US, the EU, etc., most of which are higher than the quality standards of Vietnam.. That also means, high-quality products are exported abroad, low-quality products are served domestically, while the demand for high-quality domestic products has to wait… for import. This consumption flow is the most obvious answer to prove that Vietnam has not yet established its own playing field.

Agricultural products are stuck at the northern border gates waiting for customs clearance in early 2022

It’s time for us to “enhance our self-worth”. Traditional fish sauce is okay, industrial fish sauce is okay, any product needs to meet food safety standards. Agricultural products do not wait a whole month at the border gate and then turn back to “cry” for rescue, agricultural products can go directly from the farm to the domestic consumer when they are freshest, best quality, most affordable price.

Looking at Korea – a country with many economic characteristics similar to Vietnam in the previous period, let’s look at how their KS standard certification is done.

KS (Korea Industria Standard) is considered as a national standard of Korea, largely based on the Korean Industrial Standards Act and is divided into two (product certification and service certification). Upon passing all the factory audit items of the KS certification (factory audit) and passing the test, the certificate is issued. Dossier of application for KS certification includes: Business registration, List of production equipment, List of testing equipment, List of main materials, etc. After completing the application procedures, the issuing unit KS certification will conduct an assessment at the factory with the management items of the enterprise, including:

Not stopping at this evaluation step, after all 33 evaluation items at this factory have passed, the product testing round will come. This product will have to be tested in a Korean testing laboratory. That is, if you manufacture a screw or an elevator, it also needs to be field tested with the quality impacts that this standard requires: operation, bearing, heat resistance, etc.

Not only KS, other Korean standard certifications also require product testing before licensing, so the quality of products when they reach consumers who are granted these standards have been guaranteed. Is “pre-check” still a necessary mechanism, creating a “quality filter funnel”, especially for specific product industries?

Obviously, with reference from developed countries, the construction of non-tariff barriers is absolutely necessary. This technical barrier will limit the import of low-quality products, and at the same time protect genuine domestic businesses from having the opportunity to compete and develop.

It’s time… to be “fastidious” with domestic products

A representative of a major brand of the world elevator (do not name here) once shared that they themselves have tested products and technologies in the Vietnamese market. After a period of evaluation of the effectiveness, the suitable products are kept and the unsatisfactory products are completely gone. This shows that our country has become a testing ground for some imported products. The lesson about “technological garbage” must be full of topicality in the story of imported elevators (?!)

Meanwhile, the strict implementation of regulations and standards in Vietnam is still loose and has many loopholes. The post-inspection mechanism has created favorable conditions for foreign goods to easily enter the Vietnamese market, suppressing and overpowering young Vietnamese enterprises.

That said, it’s time for us to rethink and dare to be “fastidious” with domestic products themselves. It is difficult to be fastidious, not to stifle the development path of enterprises, but to create public awareness of consumer quality. The masses here include both businesses and consumers, because these are the two objects most affected and affected by quality requirements. Only when businesses realize the importance of improving the quality of products and services can they expand their markets. Only when consumers are aware of the importance of product quality they deserve will they “require” the supply to improve quality.

It’s time for the “slogan” of Vietnam’s quality to be realized!

When Vietnam’s Quality Standards are high, that’s when our products achieve “make in Vietnam”, creating a brand that can be easily traded to any other demanding market, and that’s it. It is also the time when foreign businesses that want to enter the Vietnamese market will need to ensure the quality that Vietnamese consumers deserve. Just creating a premise for domestic businesses to improve themselves, while reducing “waste” from around the world!

“Our country is still poor” is not a reason for us to be lenient, but it is a motivation for us to build a completely new brand, a completely new personality with international friends. Therefore, it is time for us to be tough.

Luu Hien Minh