EM – Equipment components of an elevator are usually connected to each other and connected to the elevator structure, shaft and other mechanical structures by bolts and nuts, expansion screws. These connecting components have an extremely important role, related to the safety of use, the life of the elevator and many other issues.

Disaster just for replacing smaller bolts

On the morning of June 10, 1990, British Airways flight 5390 – United Kingdom with 81 passengers and 6 crew members including two pilots, took off from Birmingham to Malaga, West Spain. When the plane climbed to an altitude of about 5,300 m, the windshield of the cockpit cabin suddenly flew out and shattered, the captain was sucked half of his body out of the plane. With extraordinary efforts, the two flight attendants held the captain for about 30 minutes and during that time, the co-pilot managed to control the plane to make an emergency landing at a nearby airport. This accident, although there were no casualties, is considered very serious and the UK’s Air Accidents Investigation Bureau (AAIB) has opened an investigation to find out the cause of the disaster.

British Airways plane lost doors due to wrong bolts

The results of the investigations showed that the cause of this serious accident was the maintenance manager who directly replaced the screw that attached the windshield to the aircraft of the wrong type. Bolts fitted to the aircraft with a diameter of 0.66 mm smaller than the specification did not have enough force to hold the glass against the extreme pressure difference inside and outside the aircraft.

In another development, after a plane suffered a wing tear, a 6-meter-long tear on landing caused by four broken bolts, the Federal Aviation Administration (FAA) opened an investigation. They did a thorough check of the planes of a model that had flown over 25,000 hours and found quite a few faulty bolts that could be dangerous.

Specifications of bolts and nuts

Bolts used in elevator structures also play a particularly important role. A complete bolt connection usually consists of 4 details: Body, cap, nut and washer, including a “warping bolt” to increase friction and ensure nut doesn’t drift by the impact of vibrations, bearing large forces, etc. There are many types of bolts. These are coarse threaded bolts (normal bolts), fine threaded bolts, high strength bolts and hatch bolts. Expansion or closing bolts are widely used, including in the elevator industry. From fixing the foundation, pillar or participating in the connection of structures together, connecting rails or linking the elevator frame with the shaft, etc. The elevator hatch is specially designed with 3 washers to create steadiness for the structure. Therefore, even if the building experiences strong vibrations, it will not affect the physical structure inside.

Because of their widespread use, bolts of grade 8.8 are often counterfeited

Expansion bolts also have many types, which are stainless steel expansion bolts, steel expansion bolts made of galvanized carbon steel, hook expansion bolts also known as hooks, stud expansion bolts and hatch bolts. The expansion bolts are all specially designed with good bearing strength. Bolts have many strength levels, depending on the bolt material, divided into the following strength classes: 4.6, 4.8, 5.6, 5.8, 6.6, 8.8, 10.9, 12.9. Accordingly, the number before the dot represents 1/100 of the minimum tensile strength of the bolt (unit is N/mm2). The remainder represents 1/10 of the value of the ratio between the minimum tensile strength and yield strength (in units of N/mm2). For example, a bolt of grade 10.9 will have: tensile strength 10×100 = 1000 N/mm2, yield strength (9/10)x1000 = 900 N/mm2. In which, bolts with durability grade of 8.8 or higher are called high-strength bolts.

High strength bolts are made from alloy steel then heat treated to achieve the required torque and tensile force. High-strength bolts are made of high-tensile steel, so they can be tightened very tightly, causing the bolt body to endure tension and exert a great pressure on the connecting steel plate. When subjected to force, between the contact surfaces of the steel plates there is a large frictional force against the relative sliding between them. Thus, the force transmitted from one member to another is mainly due to the frictional force. High strength bolts have large bearing capacity, low deformation connection, so they are widely used and replace riveted connections in structures subject to heavy loads and dynamic loads.

With such high technical standards, 8.8 grade high strength bolts are also the most commonly used bolt grades in elevator installations.

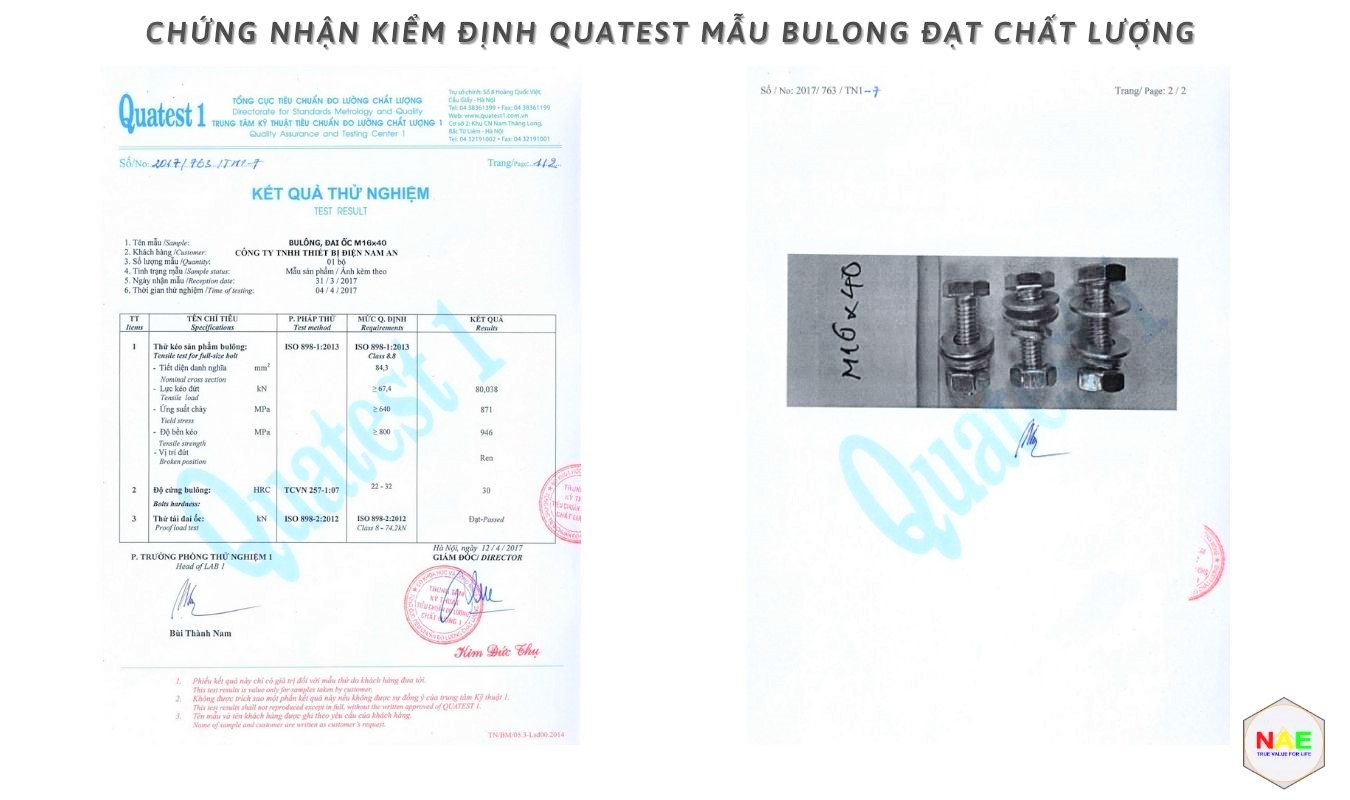

Certificate of bolt inspection

When using the connection of mechanical and precision mechanical structures, including elevators, there are strict regulations on technical standards for nuts and bolts. These standards include material, size, thread pitch, level of tension, tensile force, etc.

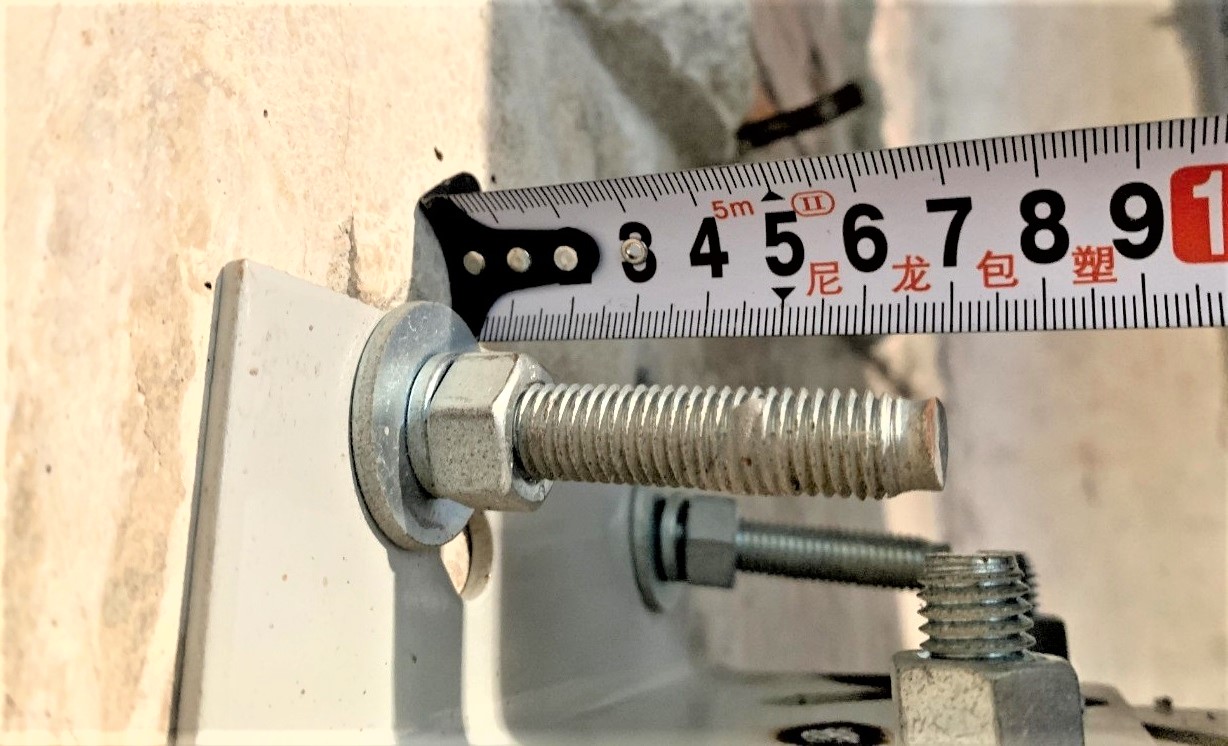

Image of an unqualified bolt that is about to break due to not being able to withstand the rated tightening force

In which, bolt tightening force is the torque force of the bolt and nut creating the initial tension, creating a firm connection. Then, the bolt will be clamped strictly according to the requirements of the technique. For each device, detail of a mechanical assembly, bolt tightening force is determined precisely before production, suitable for each technical requirement. This requirement must always be strictly complied with, ensuring technical standards to avoid damage, rust, and creep, including cases of broken nut or broken bolt.

Currently, the tightening force of bolts has been specified according to standards in construction or production. At that time, the technician needs to check and calculate the most appropriate bolt tightening force. Vietnam already has regulations on bolt tightening force standards. Those are Vietnamese Standard TCVN 8298:2009 Irrigation works – technical requirements in manufacturing and assembling mechanical equipment, steel structures and Vietnamese Standard TCVN 1916:1995 on Bolts, screws, studs and bolts. nuts – Specifications.

In addition to the regulations on the standard of bolt tightening force, the calculation of the bolt size is also suitable for the tightening force, which will determine the appropriate bolt type when designing products and equipment. Bolt size and diameter are two different criteria of bolts. Bolt diameter numbers are often confused with bolt size numbers.

The condition of tampering with bolt strength and improper bolt installation

Because of its many advantages, bolts are widely used in machinery, industrial equipment, construction works, traffic works, bridges, etc. everywhere in the world. Although important, but now the situation of counterfeiting bolts is not uncommon. Bolts are manufactured not according to material standards, not of the right grade, not of the right size, imitation of famous brands… are common in the market.

Incorrect expansion of bolts significantly reduces the connection force

In particular, due to the ability to work in the condition of joints subject to large loads, high technical requirements, bolts 8.8 are widely used. Therefore, this group of bolts is the most counterfeited. An expert from the Vietnam Institute of Lift Engineering Application analyzed, on the market today, almost only sell bolts of grade 8.8, but quite a lot of them are fake, sometimes only reaching durability level 4.8 or lower. More dangerous, some major brands of famous bolt manufacturers are also counterfeited products. Acts of counterfeiting, forging bolts that are not in accordance with specifications not only cause financial damage to the buyer, but also pose a potential risk to elevator users when the mechanical structures are not sure according to the standard.

There are a number of ways to distinguish bolt products as imitations and non-quality products.

The first is to check the appearance of bolt products 8.8. Real 8.8 bolts have delicate, sharp, pointed threads, the product is more solid, different from fake 8.8 grade bolts.

Second, check the records, documents, bolt test minutes 8.8. Testing of material, size, strength, and torque will show that the bolt is of good quality or is a fake.

Third, at a higher inspection level, the user should bring the 8.8 bolt product for inspection at a quality inspection center.

Fourth, is to choose a reputable manufacturer and distributor of fasteners and bolts. Like the world famous bolt brands EJOT, HILTI, KPF, EUBOLT… are present in Vietnam market.

Some screwdrivers have torque gauges

In addition to the fact that bolts are faked, counterfeited, there is also a situation of improperly installing bolts that are potentially dangerous for the entire elevator system. The mechanical connections in the elevator, when designed, have specific provisions for each type of bolt, in which there are requirements for the corresponding strength and tightening force. To install bolts correctly, technical personnel must first have knowledge of bolts including technical standards and disassembly procedures. Without training, these personnel will install bolts in a “only tightening is enough” manner, which is not in accordance with the design and specification. If there is not enough tightening force, the bolt will gradually loosen, leading to a reduction in the bearing capacity, reducing the connection effect, leading to dangerous incidents. If you tighten it too much, the bolt will be deformed or twisted. Tightening bolts according to design standards also requires specialized tools. Tools that include torque measurement components are often very expensive, requiring investment, but not all installers are aware of this problem. That’s not even taking into account the design of the bolt which usually includes auxiliary washers. These washers have different uses and must be placed in the correct order of positions to have the effect of supporting the link, if placed in the wrong position will greatly reduce the use. Therefore, the assembly and installation of elevators requires technical staff to be well-trained, accumulate experience, and constantly improve their qualifications.

In each finished elevator product, there are many important links using bolts such as tractor links, rails, elevator structure, safety devices of elevators, etc. These links have great bearing capacity, only a small mistake in choosing bolts not in accordance with technical requirements, using bolts is fake goods, poor quality goods, even technical staff who are not properly trained, have poor capacity, lack of experience, etc. will lead to unpredictable consequences./.

Le hun