EM – Will industry standardization create additional barriers or create opportunities for businesses and workers? How will consumers benefit? Let’s dissect the issues with Elevator Magazine for a comprehensive perspective.

The news about dirty food for many years has always been an obsession for Vietnamese consumers. Does the bunch of young vegetables have pesticides, is the meat bought in the market dirty food injected with anti-degradation drugs? At that time, the application of standards in production and farming promptly regained the trust of customers. Typical examples include VietGAP (Vietnamese Good Agricultural Practices) TCVN 11892-1:2017 Good agricultural production practices in Vietnam issued by the Ministry of Agriculture and Rural Development for each product and product group. aquatic products, cultivation and animal husbandry. It is a hint for us to see how important Standardization is in life.

The need to standardize the elevator industry

Many elevator companies only know how to complain because they have witnessed the story of “sell at any price”, or like the story of a domestic business owner who told about contracts that were lost because another unit offered such low prices that we cannot think of.

Many domestic enterprises are caught up in the race to reduce prices by cutting production costs to the point of violating the safety factor. Why not improve the quality of products and services to increase competitiveness?

Even the concepts of “misleading cheating” such as “joint-venture elevator” are still abound on advertising channels launched by businesses.

The concept of “joint venture” often makes consumers think that this is the product of the process of cooperation and technology transfer between domestic and foreign enterprises. It creates a 3rd country manufacturer brand, which although weaker than imports, but is stronger than domestic products, i.e. domestically produced goods.

Taking advantage of this mentality, although some businesses do not enter into joint ventures with foreign countries, they buy components, assemble finished products and then label them as “joint ventures” to create “luxury” products. But if standardized, what is the “joint-venture elevator” product?

In addition, the elevator industry with many stages from design, production, installation, inspection, operation to maintenance and repair all have strict requirements on occupational safety. Therefore, the human resources of the industry must be well-trained and skilled enough to meet these requirements.

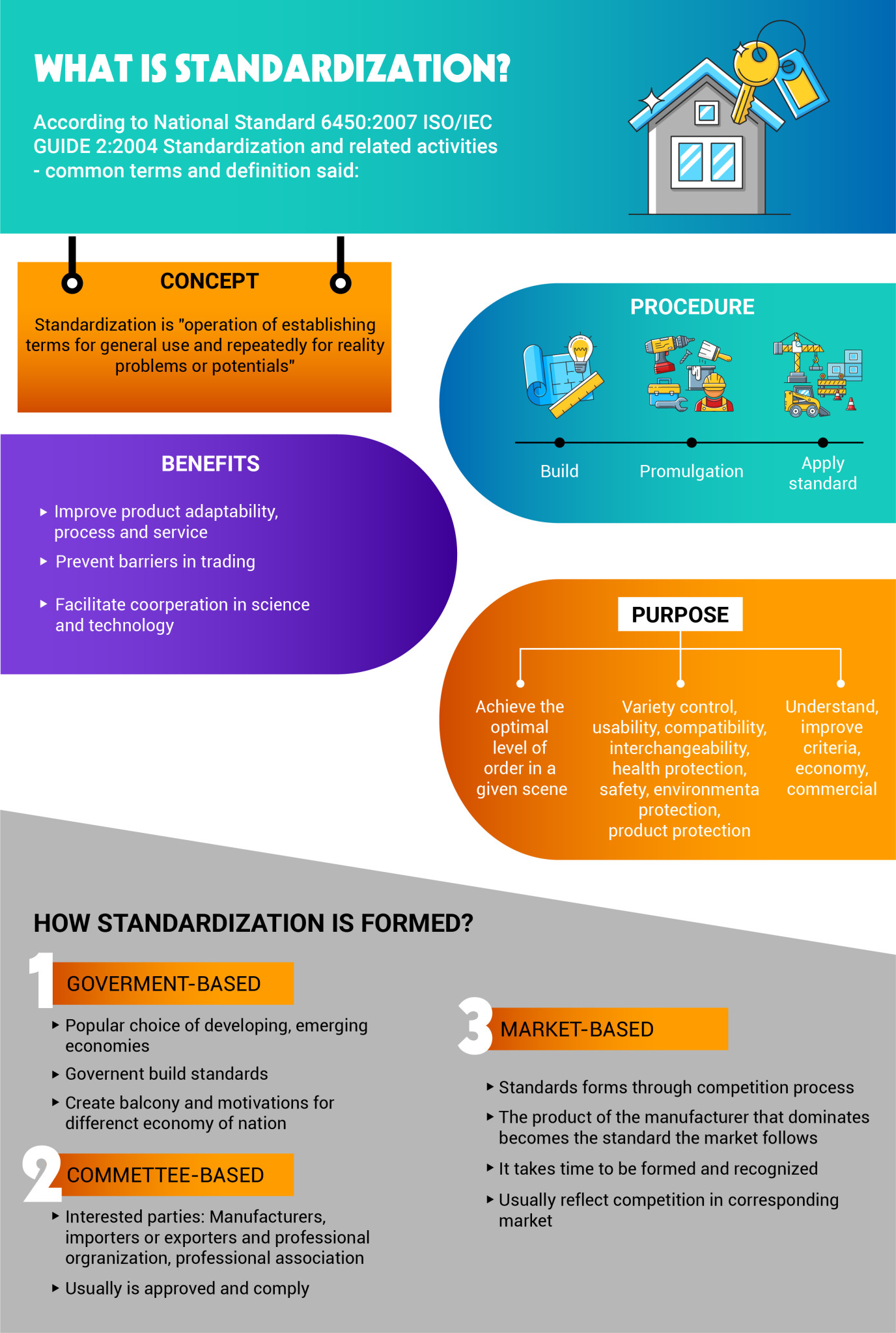

As such, standardization is all about protecting the interests surrounding the product and the market. With more than 300 elevator businesses and will increase in the coming time, the need to standardize the elevator industry is now very urgent in the face of the risk that the market will become chaotic, difficult for management, difficult for consumers and difficult even for businesses.

When the elevator industry standardizes

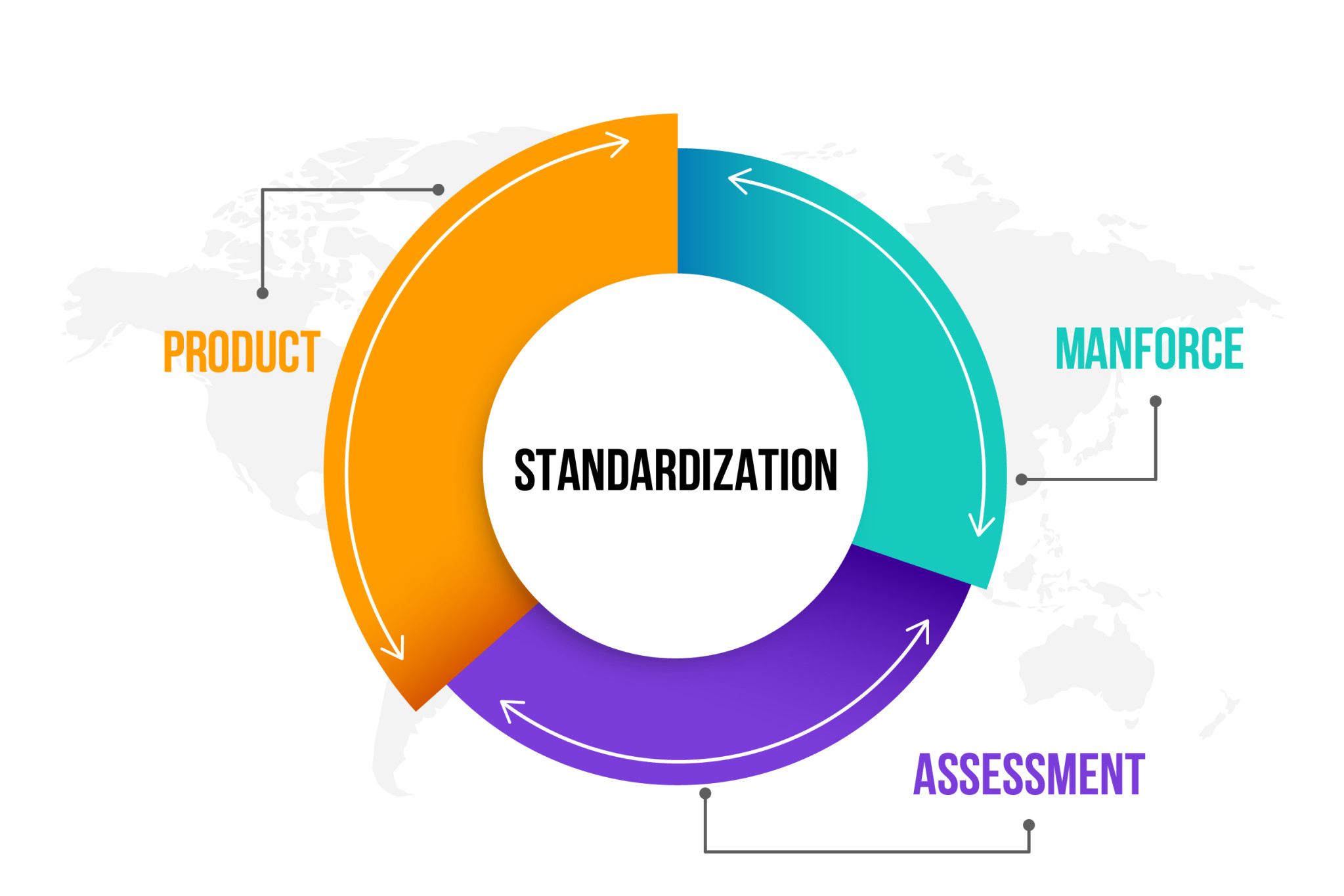

There are three areas that need to be standardized for the comprehensive development of the elevator industry: products, human resources and inspection.

1. Product Standardization

According to Clause 4, Article 3 of the Law on Product and Goods Quality 2007, elevators are products and goods of group 2: Products and goods that are likely to cause unsafety, are products and goods in transport conditions. , storage, preservation, reasonable use and right purposes still have the potential to cause harm to people, animals, plants, property and the environment.

Therefore, elevator products must meet technical regulations (QCVN) to be allowed to circulate in the Vietnamese market. In addition to technical regulations, the Vietnamese market has also applied a number of technical standards (TCVN) for elevator products. Specifically, the technical regulations and technical standards currently applied to elevator products in Vietnam are specified at: Overview of regulations and standards on elevators

The standards currently in circulation are based on technical standards from a number of highly reputable regions in the world such as Europe (EN – European Norm): TCVN 6396-20:2017 equivalent to EN 81- 20:2014, TCVN 6396-50:2017 corresponds to EN 81-50:2014, etc. The standard exists, but Vietnamese enterprises have not applied it synchronously. Most of the time, only a few importers have products that comply with the standards of the exporting country, while domestic production enterprises are not aware.

In Korea, in order to achieve certification for domestically manufactured elevator products, enterprises need to produce at least 3 out of 8 important parts of the elevator, including: control system, actuator, platform, cabin frame, counterweight frame, landing door assembly, governor, emergency stop device, buffer, landing door locking device. And whether it is a domestic product or a joint venture or an import, it needs actual testing to get certification from the KTC (Korea Testing Certification Institute).

Every bottle of French wine exported abroad has a standard certificate issued by the National Confederation of Producers of Producers of Appellations of Controlled Origin, which has made France a national holds the largest market share in the field of wine exports in the world and creates a famous traditional brand.

This answers the question posed at the beginning. Product standardization is not aimed at limiting the development ability of enterprises, but rather creating a transparent, quality and fair market for both businesses and consumers.

There is pressure to have diamonds, instead of being easy, we need to be more strict to “demand” each other better. Only then, capable businesses can assert their own value without falling into the situation of “mixed gold and brass”.

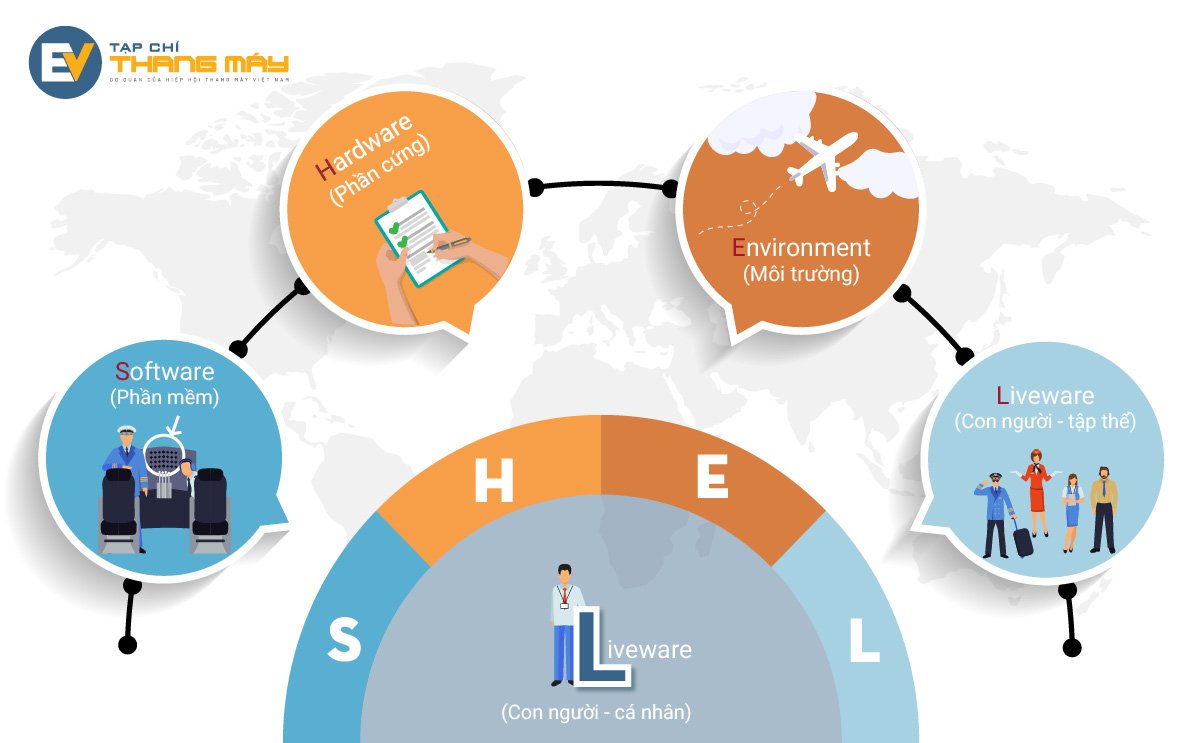

75% of aviation accidents and incidents that take place in history are related to human factors. And that is also the main reason why Korean Air – an airline of Korea, in the period from 1988 to 1998 was “labeled” with many tragedies that caused hundreds of passengers to die after each flight. plane crashed. In order to reverse the trend, this airline has invited experts to train and standardize human resources in both technical and skills. Typically, the application of the Crew Resource Management (CRM) process is issued by the US National Aeronautics and Space Agency (NASA). As a result, until now, Korean Air has become one of the safest airlines in the world.

The SHELL model is commonly applied in the CRM process, which represents the process of information interaction between individuals and other factors (software, hardware, environment and collective).

From this evidence, we can realize the importance of human resource standardization.

Up to now, human resources in the elevator industry are still mainly from the near-transfer technical industries, but there is no formal training code. Technicians at elevator companies are mostly trained in the form of “hands-on work”, the former teaches the latter, only a few reputable imported elevator companies receive training programs from big manufacturer.

Similar to elevator operation management, in large buildings, staff in charge will be trained in basic operation and often combined with other technical contents related to the building such as electricity, water, etc. However, there are no specific regulations regarding capacity review, testing, assessment and additional training.

Only standardization can set a “floor” for human resources to improve and develop.

Standardizing the inspection of the elevator industry is an assessment of both product quality and operational and safety risks of the original product, and also inspection of compliance, maintenance, and inspection periodically during the use of the elevator.

The incident that a male student at Maritime University in 2012 fell into the elevator door, suddenly the door opened, causing the male student to fall down the shaft from the 5th floor leading to his death, which raised alarm bells about technical assessment and equipment quality. The “extraordinary situation” argument is not sufficient and cannot be allowed to account for these losses.

According to TCVN 6396-50:2017 (EN 81-50:2014) Safety requirements for elevator construction and installation – inspection and testing – Part 50: Requirements for design, calculation, inspection and testing elevator parts with requirements for static and dynamic impact tests for landing doors. If this test is fully conducted, such unfortunate incidents will not occur.

Korean Industrial Standard KS (Korea Industria Standard) is considered as a national standard of Korea. In addition to the evaluation of technical parameters, information through enterprise documents, all 33 related items. to the production process are assessed directly at the factory. Not stopping at this evaluation step, after all the evaluation items at this factory are passed, there will be a product test round at the Korean Test Certification Institute.

That is, if you manufacture a screw or an elevator, it also needs to be field tested with the quality impacts that this standard requires: operation, bearing, heat resistance, etc.

Grades need to be assessed directly at the factory

This testing process can confirm the product’s ability to ensure safety, especially with elevators – products with strict requirements for safety.

In fact, if the assessment is ignored, all disasters can happen from the smallest things.

Or like a series of elevators in buildings in Hanoi, all of them are not inspected, maintained, and serviced on a regular basis as reflected by Elevator Magazine over the past time. Not only elevators in buildings where “Everybody’s bussiness is nobody’s bussiness” or management boards that do not comply with regulations are experiencing neglect in inspection and maintenance; but even home elevators are similar.

High-rise buildings in big cities are growing more and more, the need to install home elevators to serve moving needs is also increasing. However, the safety of elevators in private homes has not received enough attention, shouldn’t the inspection of elevator use also be raised to the same level as the inspection of fire prevention?

Industry standardization, who benefits?

Standardizing the elevator industry is first of all beneficial to consumers when searching and choosing products in a transparent and quality market, ensuring strict inspection and using services with skilled staff, save recruitment time for reputable businesses as well as avoid risks.

Employees are also well-trained, fully equipped with knowledge and skills to ensure safe practice and increase income by affirming the quality of skills, even aiming for opportunities to export experts and skilled workers

And businesses also do not have to suffer any disadvantages, both improving and maintaining product quality, and having abundant quality human resources, competitive value always increases, not decreases.

All organic objects in the elevator industry will benefit, promote the development of society, limit the risks of social insecurity and aim to affirm the Vietnamese elevator brand in the world market.

Standardization “needs” to become a perception for regulators, businesses, and consumers.

Luu Hien Minh

Designer: Tran Trung