EM – Regarding fire protection regulations for houses and buildings, fireproof elevator doors are an important part of the building’s fire protection system.

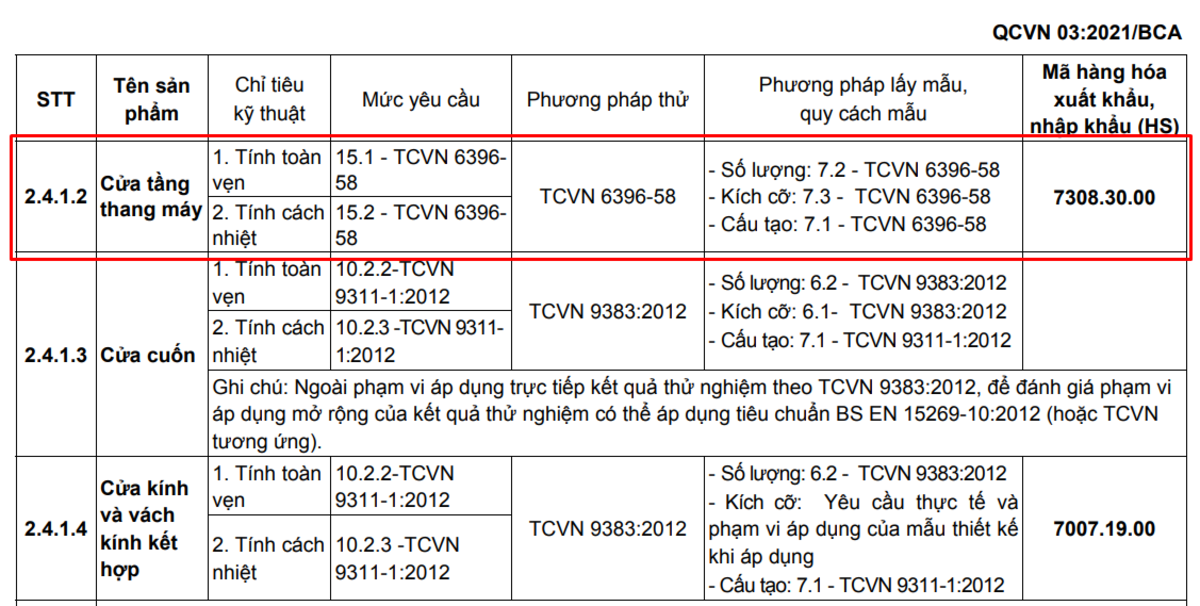

According to National Technical Regulation QCVN 03:2021/BCA on fire prevention and fighting means, elevator door products when tested for fire resistance should be applied according to the test method specified in the document National standard TCVN 6396-58.

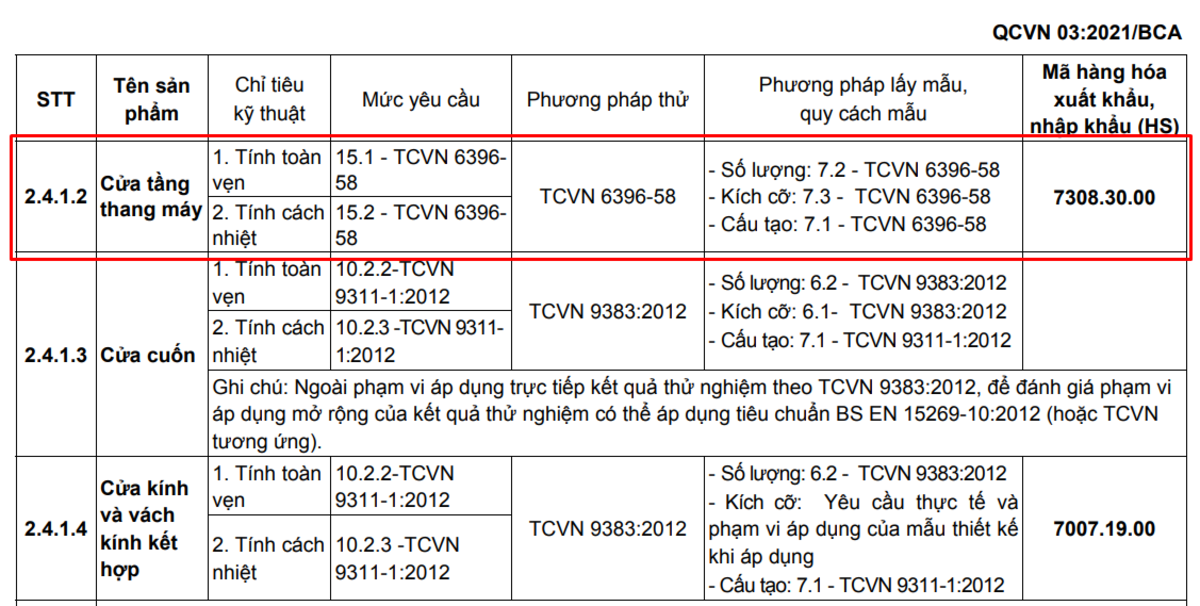

Regulations on elevator landing doors according to QCVN 03:2021/BCA.

Accordingly, in terms of structure of sample, the sample shall be sufficiently representative of the door set for the required information. That is, the testing process is forced to test on a complete system including accessories.

In section 3.5, the definition of door set clearly states, the full assembly includes the door frame or guide, panels or door panels equipped to serve for entering and exiting the parking space. The door set includes all doors, door frames, sealing material and operating components.

Regarding the sample size, the sample shall be of the actual or largest size to accommodate the furnace.

Specifically, the typical size of the furnace front door is 3 m x 3 m. For exposure, the supporting structure should have a minimum width of 200 mm for a typical furnace 3 m x 3 m, the opening in the support structure is limited to 2.6 m x 2.8 m (width x height).

Fire-resistance test of fire-resistant elevator landing doors. (Photo: ISF Elevators).

Notably, in terms of the number of sample, when the door is only exposed to heating from the entrance to the lift, only one sample needs to be tested. A second sample may be required for structural verification of the door.

In particular, according to TCVN 6396-58, the case where a second sample is needed is when the structural method prevents a detailed examination of the sample to ensure that there is no permanent damage or that the components cannot be assessed after testing, the laboratory shall use one of two options.

The second option is for the requester to supply a set of doors or part of an additional set of doors (e.g. door panels) to the quantity required for the test. The laboratory shall then be free to choose which of these sample should be tested and which shall be used for the structural examination.

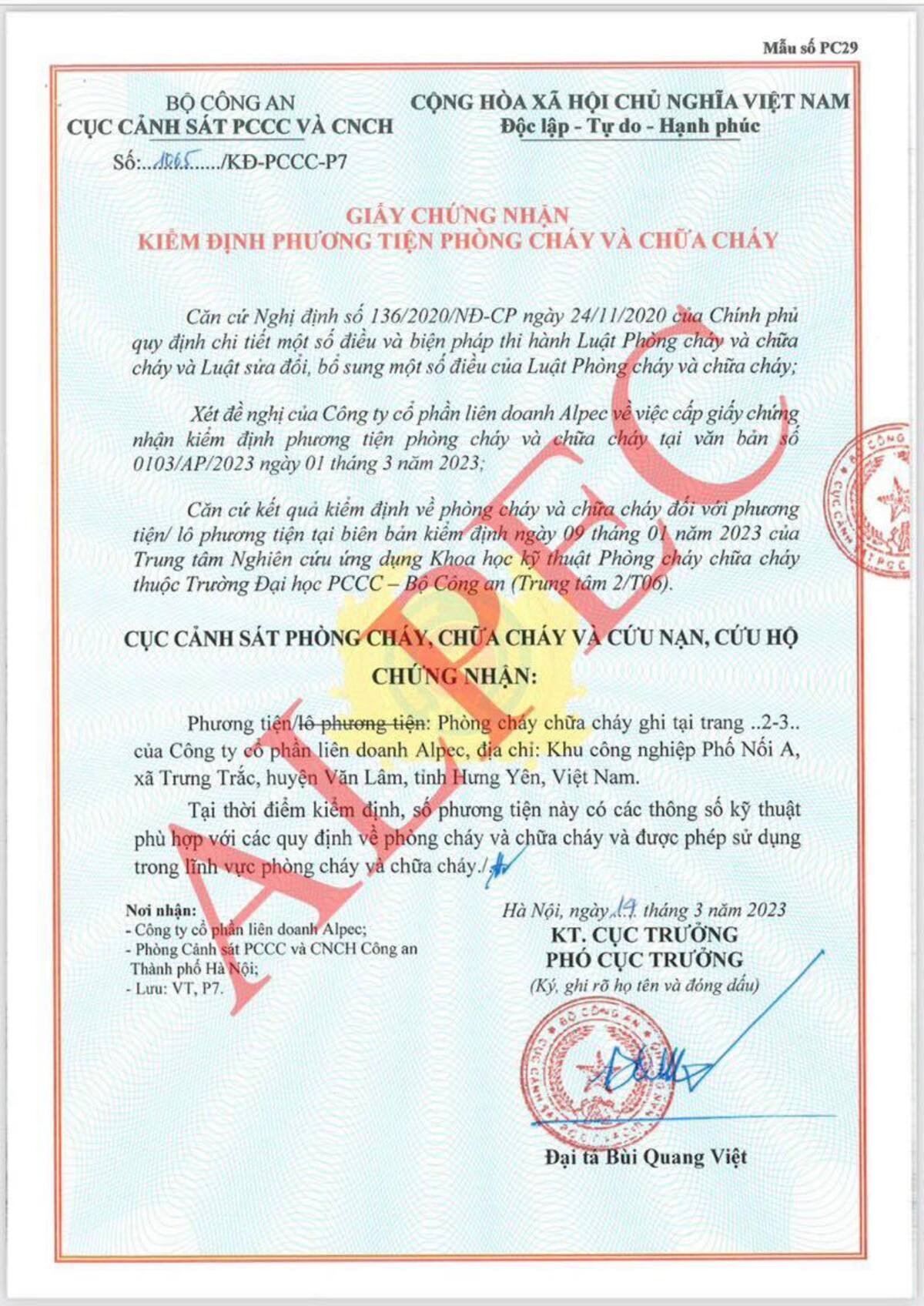

Issuing procedures for inspecting certificates.

According to the provisions of QCVN 03:2021/BCA, after performing the inspection, the testing unit is responsible for storing a sample with similar structure to the tested sample, the retention period is 18 months from the date of issue for sample inspection certificate.

In addition, the Certificate of Inspection is valid for samples of structures and components that have been sampled for testing by the unit requesting the issuance of the inspection certificate. After being granted the certificate of inspection, the structural samples are used as samples for the production and import of products to be circulated on the market.

The manufacturer or importer is responsible for the quality of the product corresponding to the tested sample when it is put on the market and in accordance with relevant laws on product quality.

Thus, this regulation does not require the issuance of a certificate of inspection of fire prevention and fire fighting for each specific project.

Certificate of inspection of fire prevention and fire fighting means of the elevator landing door, the latest model in 2023.

Regarding the time limit, the regulation clearly states that the Certificate of inspection is valid for samples of structures and components that have been sampled for testing by the unit requesting the issuance of the inspection certificate.

However, what makes some elevator manufacturers and importers in Vietnam wonder is that the Certificate does not indicate the validity period of the sample testing, whether the test sample will be valid after meeting the requirements. Is it necessary to re-evaluate and how often does it need to be re-evaluated?

In case of acceptance of international or foreign test and inspection results

According to QCVN 03:2021/BCA, for fire prevention and fighting means for which Vietnam has no standard or not specified in this Technical Regulation, the Police Department of Fire Prevention and Rescue shall base on the test conditions. According to ISO/IEC 17025 standard, consider using the test results of foreign organizations and agencies licensed by the competent authorities of the host country to consider and issue the Certificate of Inspection.

Accordingly, the ISO/IEC 17025 standard is a general requirement for the competence of testing and calibration laboratories.

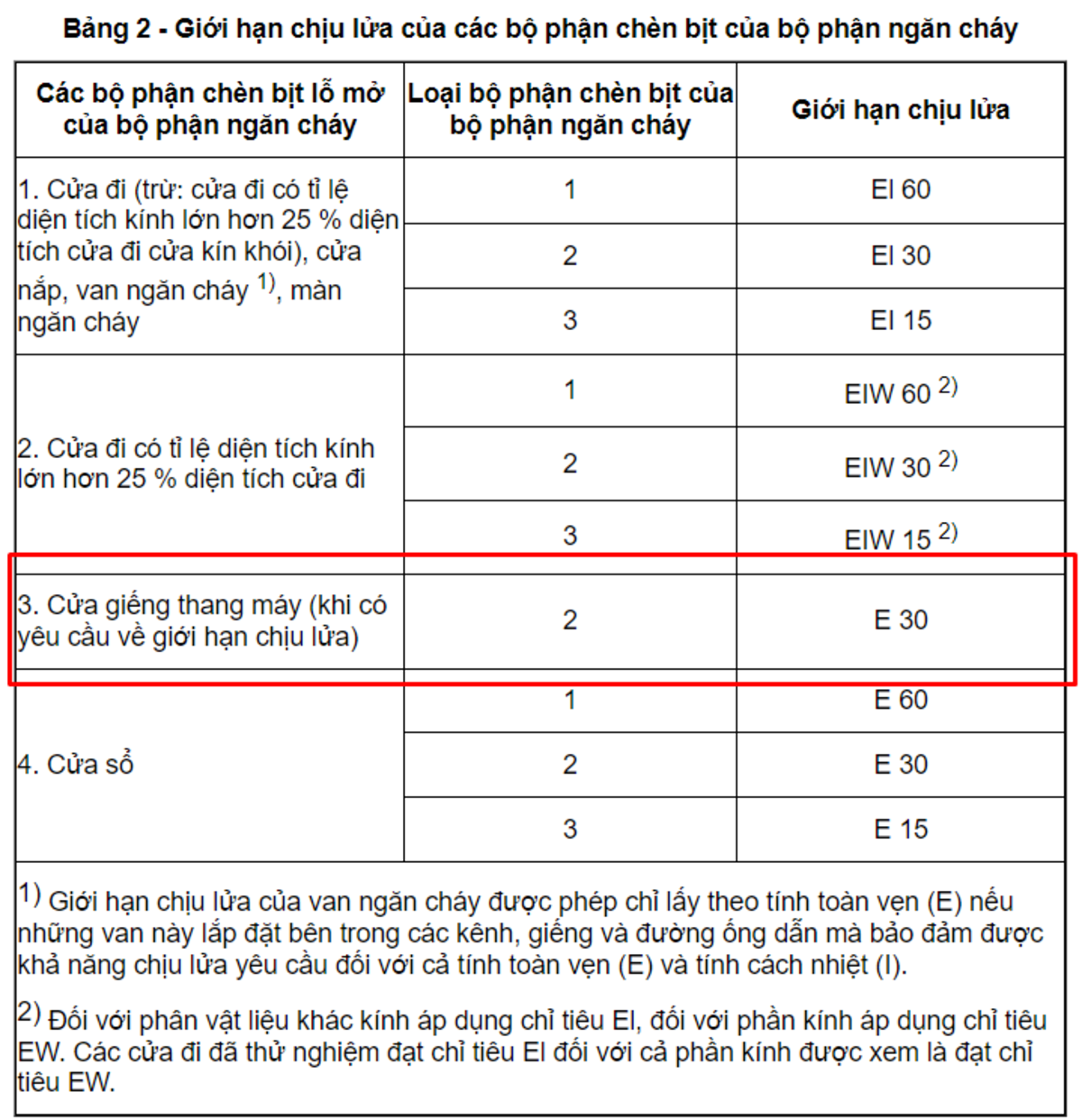

There is no clear regulation on the fire resistance level of elevator doors for each building

Regarding the issue of elevator fire doors, there is currently a difference between two standards issued by the Ministry of Construction and the Ministry of Public Security.

Specifically, according to QCVN 06:2022/BXD issued by the Ministry of Construction, elevator shaft door is defined as an entrance door designed to be installed in the shaft at the parking place to allow entry and exit of the elevator cabin.

Accordingly, the Ministry of Construction requires fireproof elevator shaft doors not less than E 30.

Regulations on elevator shaft doors according to QCVN 06:2022/BXD

Meanwhile, according to the QCVN 03:2021/BCA standard issued by the Ministry of Public Security, the elevator fire door is required to meet the integrity and insulation properties (EI).

Regarding the definition of elevator landing door, TCVN 6396-58 states that this is an entrance door designed to be installed in the shaft at the parking space to allow entry and exit of the car.

Regulations on elevator landing doors according to QCVN 03:2021/BCA

In fact, the Ministry of Construction is in charge of approving permits and the Ministry of Public Security is in charge of the inspection and acceptance of fire prevention and fighting, so the investors of the projects will meet the higher standards of QCVN 03: 2021/BCA for the construction to be tested and accepted.

In addition, there are currently no clear regulations on the EI standard requirements of fireproof elevator landing doors for each type of building. This also leads to cases where the inspection records exceed the requirements of the projects. These cases not only cause additional costs and expenses for investors but also waste social resources.

In the process of choosing fireproof elevator landing doors, if the design consultant has the capacity and experience, he will carefully study the projects and positions that need EI 30, EI 60 or EI 120. However, in the event that units and individuals want to be sure to be approved for fire protection conditions, they will require elevators to meet higher standards than actual requirements, leading to incurred costs.

Units for testing and verifying fire-resistant structures

To facilitate the organization of testing and evaluation of product quality for units manufacturing and importing fire-retardant substances and materials, there are currently 4 testing units, of which some units have different facilities scattered in the localities, licensed by the Ministry of Construction to conduct fire resistance tests as of April 2023.

Please refer to: List of testing and inspection units for fireproof structures of fireproof materials

In addition, many other testing units are in the process of being deployed and licensed at the Ministry of Construction

In addition to the regulations on fireproof elevator landing doors, readers can refer to: Regulations on fire prevention related to elevators.

The EI standard in fireproofing is a set of standards specifying the fire resistance limits of fireproof materials. This limit is determined by the time elapsed from the beginning of the fire resistance test under the standard heating regime, until the onset of the appearance of the specified state limits. Specifically:

E (Integrity) is the limit on the integrity of the material. According to TCVN 6396-58, for elevator landing doors, the integrity criterion is satisfied provided that the leakage rate per meter of doorway width does not exceed 3 m3/(min.m), excluding the first 14 min of test. Integrity is not considered satisfactory when the appearance of a flame is maintained. Sustained flame generation is one that produces a flame for a duration greater than 10 s.

I (Insulation) is the limit of thermal insulation ability, at that limit, the material still retains the thermal stability of the structure, the main structure of the material is not affected by the heat effect.

According to TCVN 6396-58, if insulation requirements apply, insulation standard l is considered unsatisfactory when the average temperature rise exceeds 140 °C.

The maximum temperature rise on door panels, top panels and side panels of a width greater than or equal to 300 mm shall not exceed 180 °C. When vertical parts and/or upper panels have a width (for vertical members) or height (for upper panels) between 100 mm and 300 mm, the maximum temperature rise of this part should not exceed 360°C.