EM – More than 40% of elevator accidents are related to elevator doors, including landing doors and cabin doors (*). From human-powered elevator door safety, we’ve made technological advancements from safety bars to infrared light curtain. At the next level of protection, we have a combination of 2D and 3D technology to increase the safety of the elevator doors.

ASME A17.1 2019 issued by the American Society of Mechanical Engineers includes new requirements for door protection.

Elevator door safety history

Historically, elevator cabins were safely controlled manually by elevator attendants, whose job was to open and close the doors and prevent the doors from closing when the doors were obstructed by passengers or objects. Having this safety controller is relatively secure, but the cost for staff at each elevator is not small. And the advancement of automation technology has solved this problem with the first automatic solution for doors and ensuring passenger safety: the mechanical safety shoe.

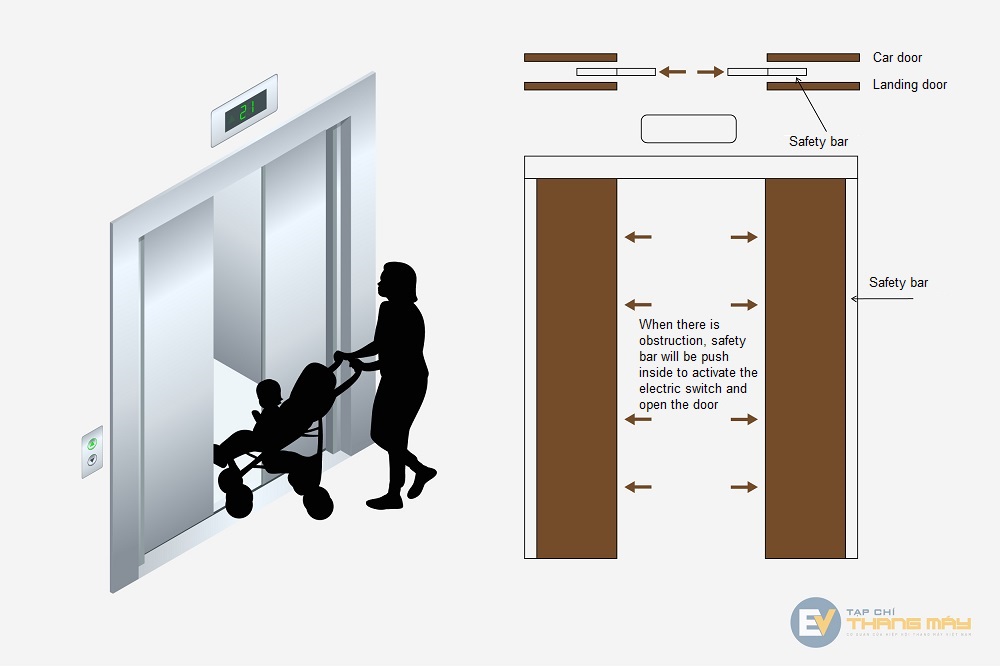

– Principle of operation: Basically, this is a switch that runs along the length of the door, which is activated when it comes into contact with an obstacle. Activate the switch (also known as the door seal or door bumper) that signals the door to reopen. The key point of mechanical edges is that they rely on kinetic energy to operate, which means they have to hit an obstacle for the switch to be activated.

Elevator door safety bar working mechanism

+ The obstacle needs a large enough force to push the aluminum bar to touch the point switch, then the door will open. May not be effective in situations where the obstacle is a soft material such as clothing, wire, etc., causing the door of the elevator to remain closed but carrying clothes, dragging people along the path of the cabin.

The door of the elevator is jammed with a soft obstacle (rope) that does not have enough force to act on the safety bar lead to drag people when the cabin moves

+ The elevator door will continuously open and close until the obstacle is removed, which will waste energy for the opening and closing operation because the safety bar only activates when there is obstacle.

+ Old technology – narrow sensing area.

In the early 1980s, Formula Systems was one of the first companies to develop an optical alternative to mechanical safety edges.

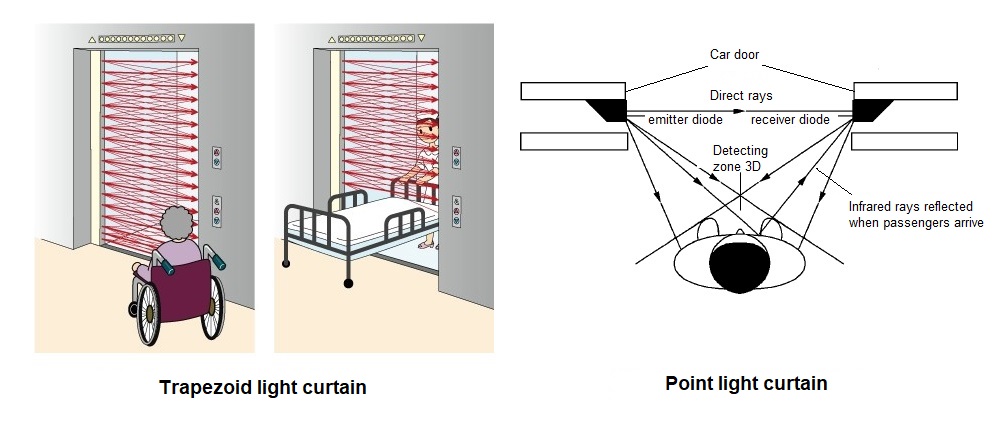

Working principle: Infrared light curtain use infrared optics to create a light curtain that effectively covers the entire door and ensures obstacle detection.

The mechanism of operation of the sensor infrared curtain at the elevator door

+ Easy to cause errors due to user or electrical system problems

+ Higher cost

Elevator jams caused by children cause error in the sensor system of the infrared light curtain

Currently, advanced elevator companies are applying a combination of both elevator door safety devices, which are safety bars and infrared blinds. With this combination, the technological disadvantages of the safety bar and infrared curtain are minimized, except for the higher initial investment cost.

Elevator safety is a journey of continuous development and improvement, a special standards committee has been formed to review safety and develop code for improvement. After years of work, the 2019 version of A17.1 has been released. Changes related to safety aspects found that the proportion of elevator incidents occurring in the car door is very high and door related incidents are estimated to account for more than 40% of all injuries in the car. To overcome this problem, a combination of means of detecting approaching objects (in addition to the existing 2D infrared light curtain) was born.

Increase the level of protection for the elevator door

Formula Systems has designed an A17.1-2019/CSA B44-19 compliant product (mentioned at the beginning) that meets both 2D and 3D requirements for object detection. All are integrated into the existing edge and require no additional equipment.

Simulate 3D sensing system when integrated into existing 2D infrared curtain system

2D sensor is the infrared curtain technology mentioned above, infrared rays to detect obstacles covered on the two sides of the elevator door (door to door). This technology only detects obstacles on the road connecting the two doors, but when integrated with 3D sensing, the obstacle detection space will be more suitable and predictive to avoid dangerous situations for people and objects.

The 3D sensors will be installed on the edges 1m above the floor, the touch scan extends 9 inches (about 0.2m) in front of the door. When objects are detected outside the door, the system will be activated to prevent the door from closing. If the object detected outside the door does not pass through the 2D detection system after a certain time, the detection signal from the 3D induction will be ignored, allowing the door to be closed. This feature helps to prevent the lift from being held for a long time to optimize traffic flow.

The scanning area of the 3D sensing system increases the space and speed of obstacle detection, which is a useful complement to the existing 2D sensing system.

Other requirements in this new technology are for 2D and 3D detection systems to perform self-monitoring checks prior to closing to confirm the two systems are functioning properly.

This solution includes a 2D/3D transmitter and receiver that can be connected directly to the elevator door controller, depending on the door controller configuration. Alternatively, a common power supply can be used for a door controller configuration that does not use a direct connection. This technology comes with options for both center opening (CO) and side opening (SO) which has a significant impact on overall installation costs. Here’s a simple alternative that doesn’t take much time; the installation process only takes up to 2 hours.

In recent times, incidents related to elevator doors such as jamming and slamming have resulted in many unfortunate casualties. With the information about the elevator door sensing technology and the bearing capacity of the elevator door, hopefully it is useful information so that users, elevator buyers can make informed decisions. In addition, readers may also read: Elevator landing doors and consumer safety.

(*): Data from Elevator World