EM – Vibration analysis is an important part of elevator maintenance as it helps detect potential problems before they become more serious, which can lead to breakdowns and elevator downtime.

Accelerometer and how it works

Imagine that your accelerometer is like a stethoscope that a doctor use to diagnoses for an elevator

Basically, it can monitor the vibration signal from the elevator and show you the values of these vibrations on a vibration meter or analyzer.

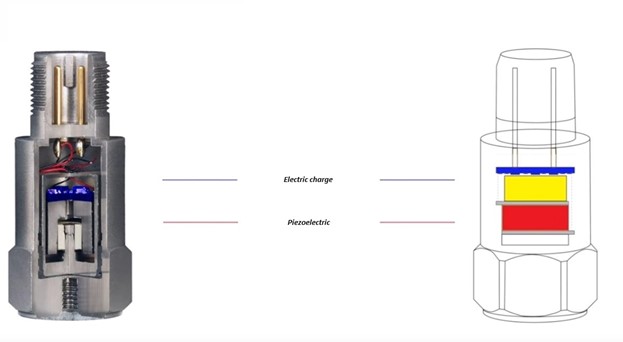

The most commonly used accelerometer in industry is the piezoelectric accelerometer.

A piezoelectric crystal generates an electrical charge when it is deformed – that is, compressed or stretched.

Inside of the piezoelectric accelerometer – Source: Adash.com

Electric charge is transferred to the electronic part of the sensor, which is converted into a voltage. This voltage is then transferred to the vibration meter via the sensor connector and cable.

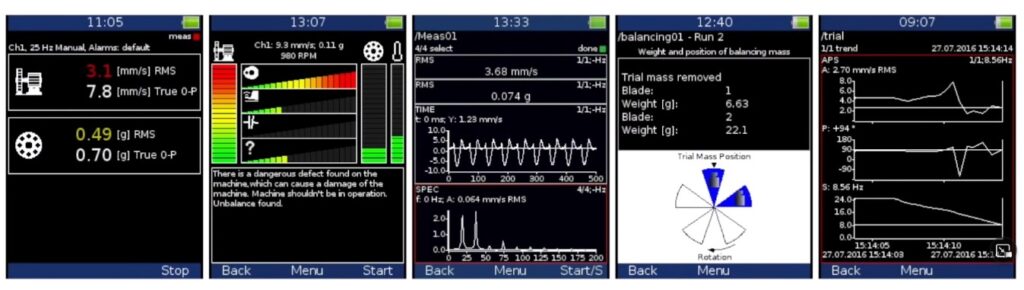

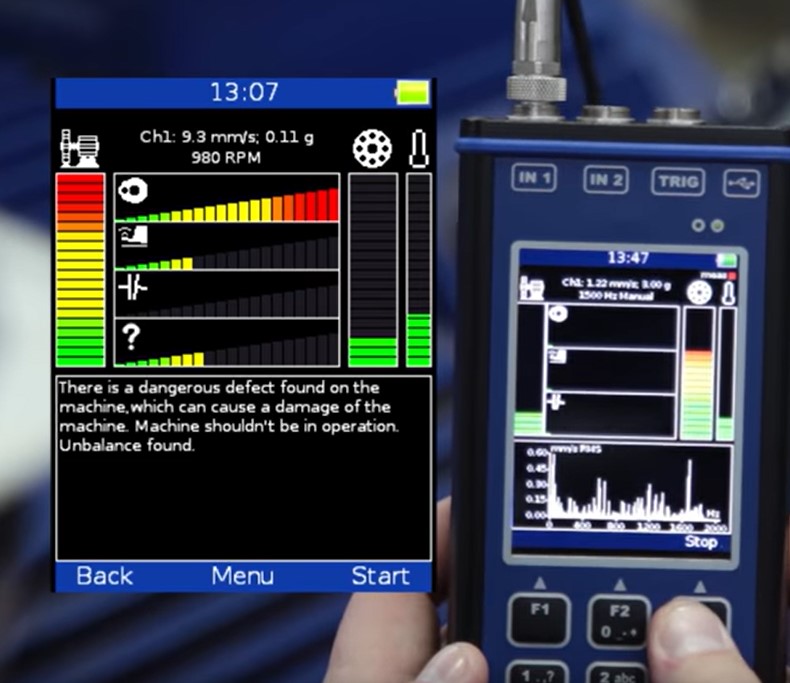

A vibration meter or analyzer is an electronic device capable of processing vibration signals. Imagine that a vibration meter or an analyzer is a voltmeter. The sensor is generating a voltage signal while it vibrates on the machine. This voltage signal is transmitted through the cable to the vibration measuring device.

But the vibration meter will not show the volts. The device is smarter than that voltmeter. Vibration meters can process voltage signals and display vibration values such as acceleration and velocity.

Source: Adash.com

What is the standard of vibration value?

The ISO 18738:2003 standard provides guidance on how to measure and analyze vibration data. It includes specifying the measuring equipment, instrumentation and measurement procedures that should be used. It also provides guidance on how to assess exposure to vibration, taking into account factors such as intensity, frequency, and duration of vibration.

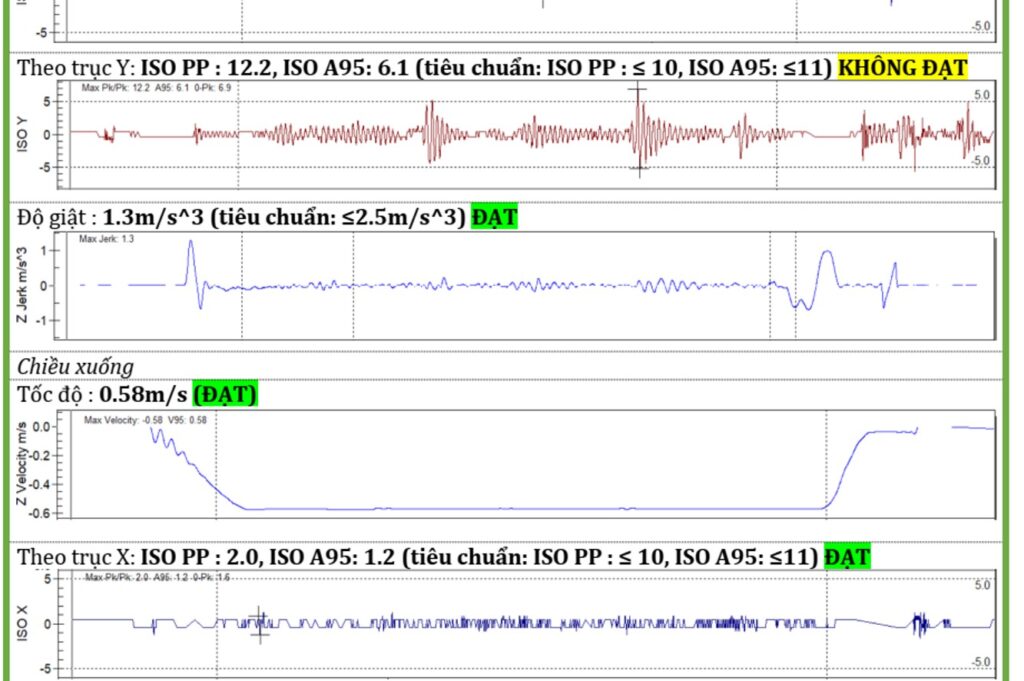

Accordingly, ISO PP ≤ 10 and ISO A95 ≤ 11 values are specified.

ISO PP and ISO A95 are the maximum vibration levels, understood as the largest of all “peak values” obtained on the oscilloscope.

Diagram of measuring vibration at a project

Alternatively, the software can automatically set limits based on statistics from previous measurements.

All mechanical errors related to machine speed such as unbalance, misalignment and mechanical looseness will give low frequency vibration. High frequency vibrations are related to bearing or gearbox failure. These vibrations are measured in velocities in mm/s or inches/s. With the accelerometer, the meter can convert the value to a velocity value.

Benefits of performing elevator vibration analysis

Vibration analysis can help detect potential problems before they become more serious problems that can lead to equipment failure and downtime. Detecting problems early allows predictive maintenance to be carried out, minimizing equipment repair or replacement costs.

Performance comparison chart of maintenance types: Troubleshooting, Preventive, Predictive Maintenance – Source: Adash.com

Vibration analysis can help identify potential risk problems of elevator components. This helps prevent accidents.

Vibration analysis can help reduce elevator downtime. This is because vibration analysis allows predictive maintenance to correct faults just before failure occurs.

Vibration analysis can detect potential problems early, avoiding costly repairs and equipment replacements.

Challenges of elevator vibration analysis

Elevator operating conditions: Elevator operating conditions can affect the accuracy of vibration measurements. For example, if the elevator is operating at a high load or operating continuously for a long period of time, the vibration may not be measured accurately.

Measuring time: Elevators are normally operated continuously and non-stop, therefore, the measurement time must be chosen so that it does not affect the operation time of the elevator. The measurement time should also be sufficient to ensure that all components of the elevator are tested.

Environment: Surrounding environment can also affect the accuracy of vibration measurements. If there is strong vibration or electromagnetic interference in the surroundings, the vibration can be affected.

Tester experience: Measuring elevator vibration requires experience and skill. If the tester is not experienced enough or does not understand the elevator components well, the measurement results may not be accurate.

Vibration diagnostics can help detect faults on elevators before they fail. By doing so, it can help predictive maintenance and reduce maintenance time, resulting in improved performance and cost savings./.

Ha My