Supporting industries are identified as having the core role of sustainable industrial development. However, at present, Vietnamese supporting industry enterprises, including those manufacturing elevator components with modest quantity, mainly produce simple details, with low content and added value, difficult to compete with foreign enterprises. In that context, it is necessary to have a comprehensive and legal corridor for supporting industry to develop, worthy of the supply chain of parts and accessories of a developing industry.

High production but low added value

That is the assessment of domestic and foreign economic experts about Vietnam’s manufacturing and processing industries. Accordingly, in recent years, the processing and manufacturing industries accounted for nearly 40% of the total net production and business revenue of the economy, but only accounted for nearly 16.5% of GDP, which was much lower than many countries in the region and in the world. Looking for the cause, economic experts said that the factors that are considered as input strengths of an industrial production industry are human resources, raw materials, semi-finished products, technology, etc. It is considered that the advantage when having cheap or reasonable prices will attract investors, the output products will be highly competitive and the economy will accumulate added value. However, our strengths in raw materials and on-site human resources often do not come into play when we import semi-finished products because of poor processing technology, along with unqualified human resources, using outdated technology, etc. These are also the weaknesses that make supporting industry unable to develop. These factors make domestically produced products have high prices but low added value and low competitiveness.

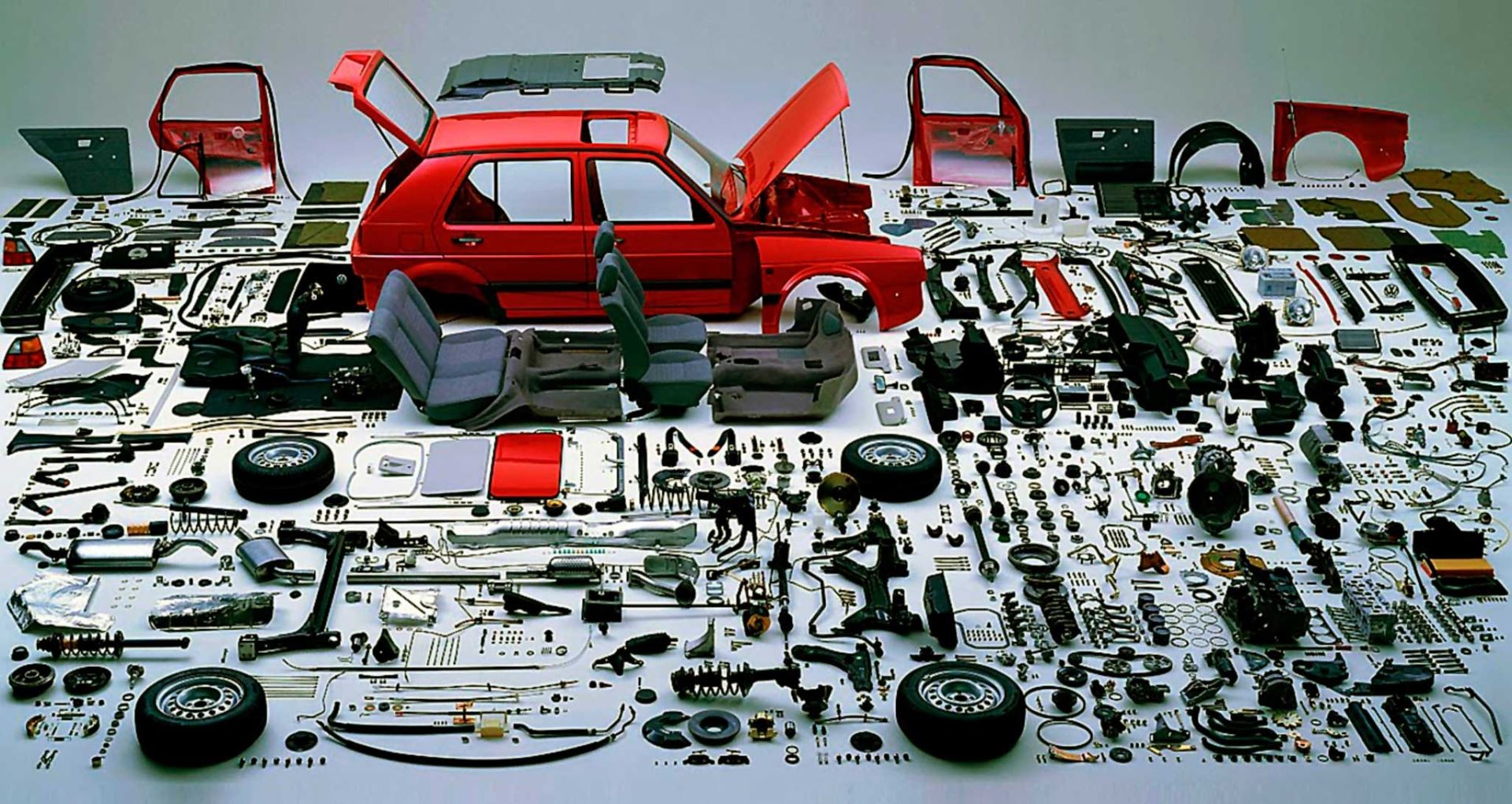

80% of the total nearly 30,000 components of a locally manufactured and assembled car are imported

Talking to reporter of Elevator Magazine, Mr. Duong Danh Ta, Chief of Office of the Vietnam Association of Supporting Industries (VASI), said that out of more than 150 members of the Association are supporting industry enterprises, there are not any businesses. which specializes in manufacturing elevator components and accessories. There is only one enterprise that “adds” a detail of the elevator, which is the electrical cabinet. According to statistics from the Vietnam Elevator Association, up to this point, the country has about 300 enterprises operating in the field of elevators, and 1,500 individuals and organizations related to elevators. In recent years, every year, over 35,000 elevators are put into use, of which about 5,000 complete products and over 1.7 million elevator equipment for domestic production and assembly are imported into Vietnam. With such a large market size and development potential of the elevator industry, but the Association of Supporting Industry does not have a single enterprise manufacturing elevator components and accessories, it is difficult to accept.

According to the Vietnam Automobile Manufacturers Association (VAMA), up to 80% of the nearly 30,000 components for domestic vehicle production and assembly are imported. Specifically, according to the announcement of the Ministry of Planning and Investment, after nearly 30 years of development, Vietnam auto supporting industry has only produced 256 parts and assemblies for cars with less than 9 seats, 14 parts. and assemblies for cars with over 9 seats and 17 parts and assemblies for trucks. This list does not include important details such as the engine, transmission, gearbox, safety system or electronic systems on the vehicle.

Where is Vietnam’s elevator supporting industry?

Through studying the websites that supply elevator components and accessories in Vietnam, it shows that customers can easily buy a lot of components and accessories of an elevator, including many important details, such as motors, inverters, microprocessor boards, inverters with integrated microprocessors, control cabinets, dedicated wire ropes, overspeed protection devices, etc. Read carefully, almost all components and accessories such items are imported into Vietnam.

Production of elevator components at Tan Lap Elevator – Mechanic Co., Ltd – one of the few enterprises specializing in the production of elevator components

Meanwhile, enterprises in the supporting industry of Vietnam’s elevator manufacturing industry is few, but only produce simple, bulky details with low content and added value such as walls and doors, mechanical frame, counterweight parts of traction elevators, some types of electrical cables and some other details such as cabinets of electrical components, lighting system for elevators, cabin floors, acrylic ceilings inside the cabin, handrails, etc. Most of these details are only used in low-segment elevators. Because elevator components and accessories are domestically produced with low technological content and low importance, they have low added value, and are not attractive to domestic manufacturing investors. Another factor that makes many investors not interested in investing in manufacturing elevator components and accessories is the market size is not large enough, the demand for the product is low, so the profit is not high.

That is not to mention, many foreign supporting industry enterprises due to optimizing production, having a stable local supply of raw materials, regularly updating new technologies, so products in the same segment have very competitive prices, making them affordable. Our supporting industry businesses lost customers right at home. As a result, the supporting industry system for elevator production is meager and undeveloped, which is one of the causes of waste of human resources, resources, foreign currency bleeding, etc.

What solution to develop supporting industry?

For the elevator industry, there is a paradox that the price difference is huge, even for elevators that are said to be domestically produced. Accordingly, some types of elevators advertised as “joint ventures” are assembled in the country at very cheap prices compared to even those made in China. An elevator expert exclaimed, with such an unreasonably low price, even the most connoisseurs do not know where they manufacture components, according to which standards to assemble these products to have such a cheap elevator. Therefore, many businesses also want to invest and transfer technology of big elevator brands for domestic production but are afraid of the chaotic situation of the elevator market and the current unfair competition.

Elevator components factory

In that situation, according to the Steering Committee 35 of the Ministry of Industry and Trade, in order to develop the supporting industry, ensure the source of raw materials, components and accessories and increase added value, it is necessary to first review and build mechanisms, new policies in line with integration commitments to support industrial enterprises’ development, develop new policies in management and investment attraction to ensure FDI enterprises have linkage and transfer technology. One of the important solutions is to develop and enforce an appropriate system of technical regulations and standards in the industry to protect domestic producers and consumers and strengthen the inspection of the quality of import industrial goods and use technical barriers to reasonably protect the domestic market, in line with international commitments and practices.

Along with that, economic experts said that the Government should continue to research and soon submit to the National Assembly for promulgation the Law on Supporting Industry to create conditions for businesses to participate in this field. In addition, many supporting industry enterprises also recommend the Government to issue appropriate and specific policies for quality control, transparency of the origin of components, accessories, imported products, and have policies supporting industry develops and increases the substantive localization rate by specific and effective regulations…

Le Hung