EM – In response to concerns about the “wave” of old elevators, many countries have implemented programs to support the renovation of old elevators or put forward requirements for maintenance and modernization of existing elevator systems to return them to the safest state for users.

Mr. Eric Darmenia

Secretary of the Pacific Asia Lift and Escalator Association

Jardine Schindler Group Senior Consultant

Existing elevators and solutions in maintenance and modernization are some of the outstanding issues raised at the PALEA/VNEA Lift and Escalator Seminar held in October 2023, Hanoi. In his presentation, Secretary of the Pacific Asia Lift and Escalator Association Mr. Eric Darmenia also presented solutions and methods that many countries are applying to address these concerns.

According to Mr. Eric Darmenia, facing concerns about existing elevators, especially old elevators, regulators and elevator associations in Asia Pacific actively promote the modernization of existing lifts to enhance safety.

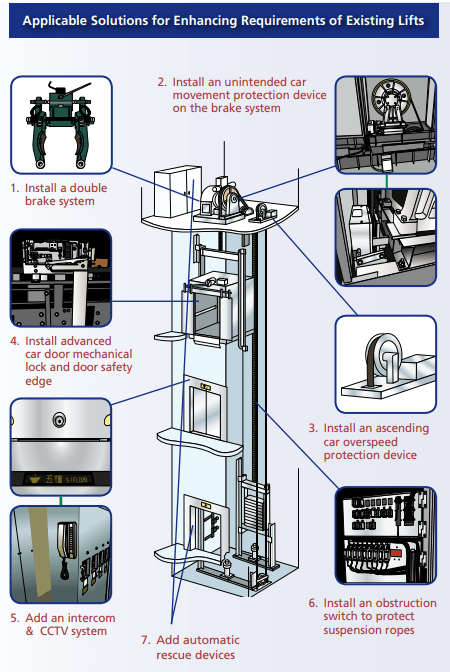

Mr. Eric Darmenia also pointed out some specific examples of initiatives for modernization from Regulators. Such as the Electrical and Mechanical Services Department (EMSD) has dedicated web pages for maintenance and modernization. EMSD also offers 7 applicable solutions for enhancing the requirements of existing elevators.

1. Install a double brake system

2. Install an unintended car movement protection device on the brake system

3. Install an ascending car overspeed protection device

4. Install advanced car door mechanical lock and door safety edge

5. Add an intercom and CCTV system

6. Install an obstruction switch to protect suspension ropes

7. Add automatic rescue devices

The Government of Hong Kong has partnered with the Urban Renewal Authority (URA) to implement the “Lift Modernisation Subsidy Scheme” to promote elevator modernization in the community.

This program works by providing the provision of financial incentives with appropriate professional support to eligible building owners of private residential or composite (commercial and residential), thereby enhancing lift safety.

In South Korea, the Korean Elevator Safety Agency (KoELSA) also published regulations in the management of elevator systems such as elevators operating over 15 years must have regular inspection of safety components; and elevators operating over 21 years must have 8 specified safety components.

According to the latest data published by the European Lift Association in 2019, more than 6,150,000 lifts are installed there, many with more than fifteen years of service. The modernization of these elevators has generated in 2018 a turnover of more than 1,629 billion euros.

Keeping old elevators in safe working order has been the main job of many elevator companies in Europe and increasingly globally.

In addition to national solutions, PALEA Secretary Eric Darmenia also provided solutions and methods by which the existing passenger and passenger goods elevator system can be upgraded and modernized to ensure safety standards through EN 81-80 (Safety Norms of Existing Lifts – SNEL).

This set of standards is the result of many years of work by elevator safety experts, government agencies, inspection bodies, consumer organizations, maintenance companies, and others.

EN81-80 – Rules for the improvement of safety of existing passenger lifts and goods passenger lifts were first published in 2003 with an updated revision published in 2019. Specifically, in EN 81-80:2003, the elevator must be audited based on a list of 74 safety risks.

In the revised standard – EN 81-80:2019, the list of elevator safety risks is updated with 11 new hazards, increasing 74 safety risks from the old standard to 85 risks. This new EN 81-80:2019 version helps to reduce safety gaps, bringing the safety level of existing old elevator systems closer to the level of new elevators being introduced to the market.

According to Mr. Eric Darmenia, EN 81-80:2019 can be used as a basis for elevator owners, management agencies, and enterprises to identify and categorize various hazards and hazardous situations. In parallel, EN 81-80:2019 also provides corrective actions to improve safety based on a list of safety risks.

Safety risks are also classified into high, medium, and low severity categories with corrective actions that can be applied and prioritized. In addition, the list of safety risks provided can be used as a checklist to audit existing lifts to identify potential hazards.

In addition to the solutions proposed by the PALEA Secretary, the presentation “The ‘gaps’ in Vietnam Elevator Regulations, Standards and Initiatives from VNEA” by Dr. Nguyen Duc Hanh – Director of the Vietnam Institute of Lift Engineering Application, also offers initiatives in building TCCS/VILEA Industry Standards.

This set of standards also addresses the issue of elevator modernization, providing detailed recommendations on the lifespan of the elevator’s main equipment as a basis for building an elevator overhaul and modernization plan.