When considering buying a product or choosing a service, many people will probably rely on two criteria of quality and appearance. But do we fully understand the quality criteria? Especially for the group of products and goods with the potential to cause unsafety (group 2), the quality criteria must be put on top because this group of goods themselves, even though they have been transported, stored, properly preserved and used for the right purposes but still potentially harmful to people, animals, plants, property and the environment.

So what requirements must quality goods meet?

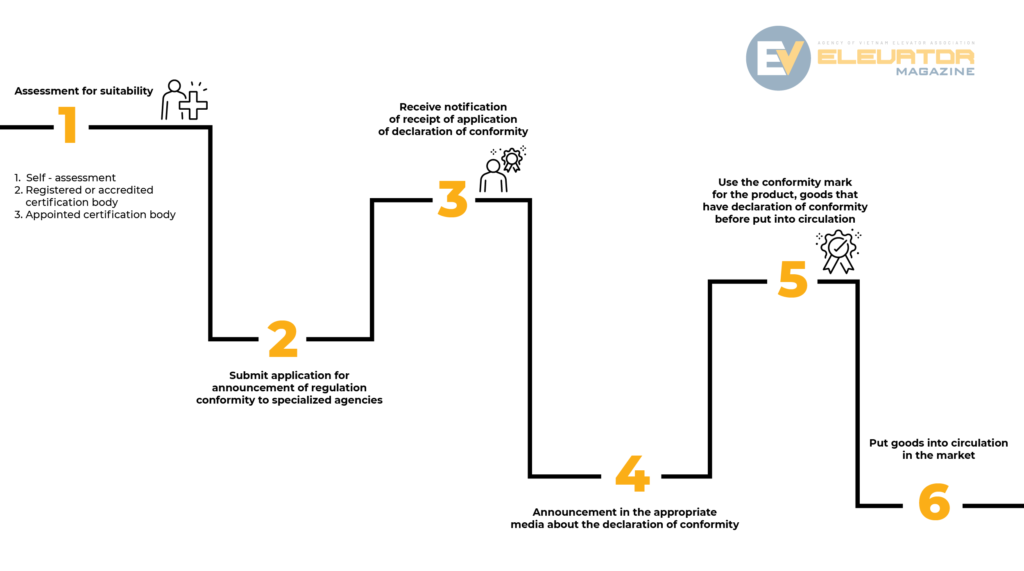

According to the provisions of Clauses 7 and 9, Article 3 of the Law on Standards and Regulations 2006, technical regulation conformity certification and announcement is the confirmation and announcement of objects (Products, goods; Services; …) in accordance with the relevant technical regulations.

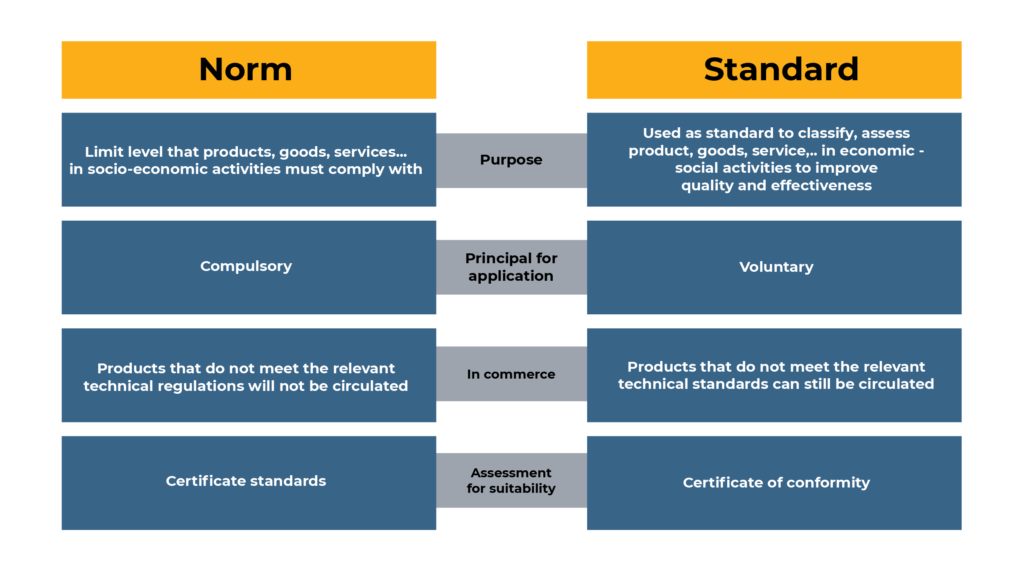

Technical regulation is a regulation on the limits of technical characteristics and management requirements that products, goods, services and other objects in socio-economic activities must comply with to ensure safety, hygiene and human health; protection of animals, plants and the environment; protect national interests and security, consumer interests and other essential requirements. Technical regulations promulgated by competent state agencies in written form for compulsory application.

Consumers must often read product descriptions from businesses with the phrases: “standard goods”, “certified products according to technology standards”, “standard goods”, “high quality”,… Consumers may be confused by this “concept forest”. So how do “regulations” and “standards” really understand?

Products that do not meet technical standards but meet technical standards are still allowed to circulate normally

As analyzed above, regulation conformity certification and declaration of conformity are made mandatory for products, goods, services, etc., which are subject to regulations in the respective technical regulations.

Not all products require certification and declaration of conformity. According to Article 5 of the 2007 Law on Product and Goods Quality, products and goods that are likely to cause unsafety (group 2) must be quality controlled on the basis of relevant technical regulations set forth by management agencies. promulgated by the competent authority and the standards announced by the manufacturer apply.

According to Circular 36/2019/TT-BLDTBXH on the list of machines, equipment, supplies and substances with strict requirements for occupational safety and hygiene, elevators are ranked 21st and belong to the group. Subjects must be certified and announced of conformity before being put into circulation on the market.

In Article 5 of Circular 28/2012/TT-BKHCN, there are 8 methods to certify conformity. Conformity assessment will be carried out by one of the following methods:

– Method 1: Testing of typical samples;

– Method 2: Testing of typical samples and evaluating the production process; supervision through testing of samples taken in the market;

– Method 3: Testing of typical samples and assessment of the production process; monitoring through testing of samples taken at the production site in conjunction with assessment of the production process;

– Method 4: Testing of typical samples and assessment of the production process; monitoring through testing of samples taken at the production site and on the market in combination with assessment of the production process;

– Method 5: Testing of typical samples and evaluating the production process; monitoring through testing of samples taken at the production site or on the market in conjunction with assessment of the production process;

– Method 6: Evaluation and monitoring of the management system;

– Method 7: Testing and evaluating batches of products and goods;

– Method 8: Testing or verifying all products and goods.

The method of certification of conformity for elevators and their safety parts is according to method 5, method 7 or method 8.

Products and goods that are not tested and evaluated for conformity with standards before being put on the market will contain many potential risks in terms of quality and safety during operation and use. Certainly, no consumer wants to put themselves in a game of “may” – “risk” with the product they have chosen. And no one wants it, itself is the experimental place of the manufacturer because they have previously “burned the stage” and put the product into circulation on the market.

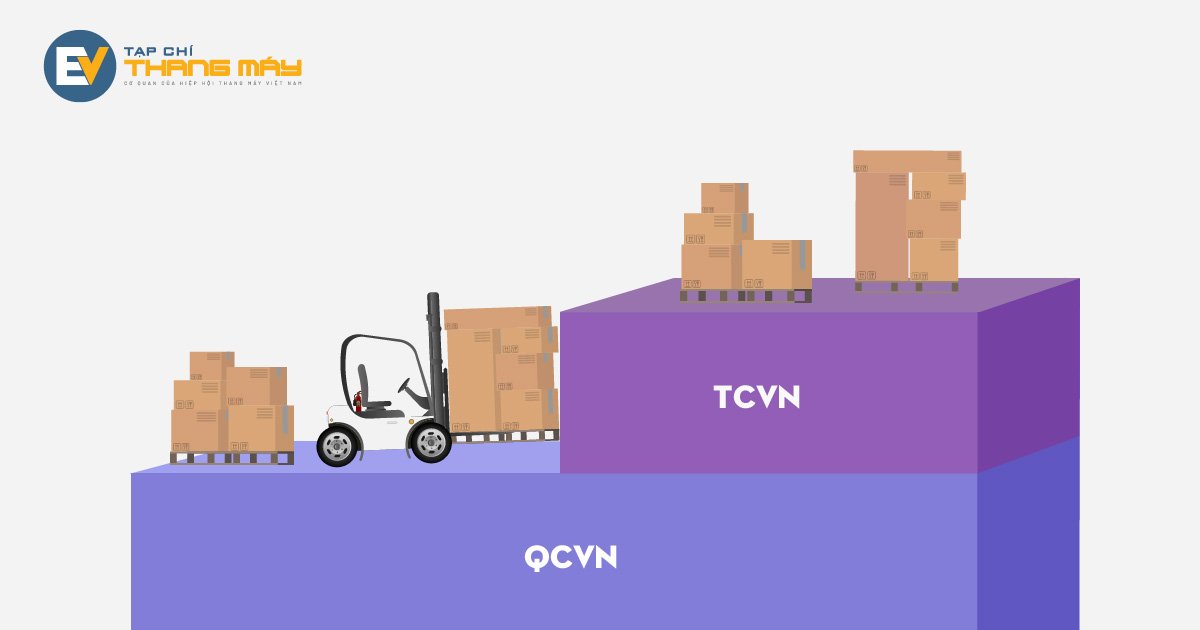

For groups of products and goods produced domestically:

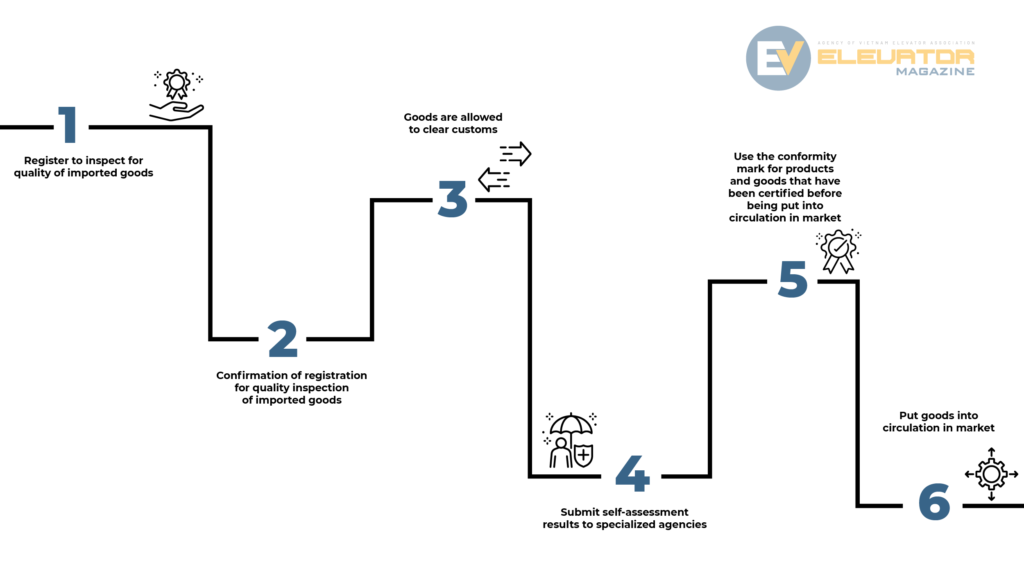

For groups of imported products and goods:

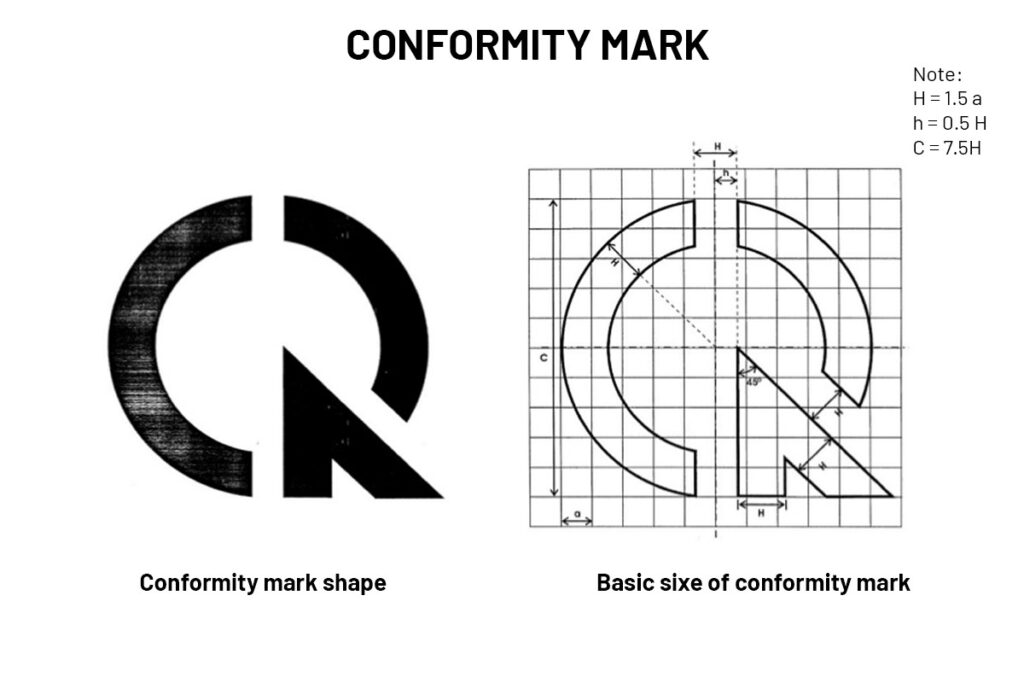

To determine whether a product or group of goods of group 2 is certified and declared to be in conformity with the regulation, consumers can visually observe whether the products are affixed with the conformity mark or not.

The shape and size of the technical-regulation conformity mark are specified in Appendix I of the Circular No. 28/2012/TT-BKHCN of the Minister of Science and Technology:

In addition, consumers can request the manufacturer to provide a true copy of the original document: Notice of receipt of dossier for announcement of regulation conformity or Certificate of conformity with technical regulations or Notice of inspection results. state on the quality of imported goods.

According to the provisions of Circular 42/2019/TT-BLDTBXH on the National Technical Regulation on occupational safety for elevators (QCVN 02:2019/BLDTBXH), requirements for domestically manufactured and imported elevators Imported products before being put on the market must be certified in accordance with this standard by a certification body designated or recognized by the Ministry of Labor, War Invalids and Social Affairs.

At the same time, the regulation conformity must be announced according to regulations and subject to inspection and supervision by product and goods quality inspection agencies. Contents of regulation conformity certification for elevators and elevator’s safety parts. Elevator safety components, including:

– Locking device for landing door and cabin door (if any);

– Safety brake;

– The brake system of the drive;

– Overspeed controller;

– Shock absorbers;

– Shut-off valve/one-way valve.

The assessment and certification of conformity for elevators and elevator’s safety parts must include the following contents: Examination of design documents, elevator history. Carry out inspection/testing of elevator safety components/devices.

The certificate of conformity must show information about the elevator, including:

– Code;

– Manufacturing number;

– Manufacturer;

– Origin;

– Year of manufacture;

– Technical characteristics (Type of elevator, load, rated speed, number of stops, number of people allowed in the elevator).

Conclusion about the design conformity of the elevator design or the safety parts of the elevator in accordance with the requirements specified in this regulation.

During use, the organization or individual managing the elevator must keep the certificate of conformity of the elevator.

Practice shows that many organizations and individuals that manage and use elevators still do not understand or are not interested in regulations on certification and announcement of conformity. Therefore, the risk is already present before the product is put into use. Conformity certification can be considered as a “safety line” for potentially unsafe devices such as elevators, which consumers need to pay special attention to.

It is the information that is confirmed during the regulation conformity process that will help consumers be assured of the origin and quality of the product, avoiding situations where businesses use mixed real and fake equipment and parts. put together and then sell to customers, posing a risk of unsafety during use.

In order to be proactive and be sure of the conformity certification information, consumers can follow the recommendations of experts of the Vietnam Elevator Association:

– Request the elevator supplier to provide full documents and papers related to the original elevator for inspection, avoiding the situation where the enterprise only applies for one set of documents but uses many copies to deceive. customer.

– The method of certification of conformity (with the elevator being method number 5, 7 or 8) depends on the way the elevator is manufactured, if the mass-produced elevator has the same design of all products, it will method 5, while the single-unit design is implemented according to mode 8. Consumers need to clearly determine which elevator design they buy to check and certify.

– Check all documents related to the elevator to confirm whether the information is consistent or not, in the case of imported elevators, documents such as B/L (Bill of Lading), Packing List, Certificate of Origin, Certificate of Quality and Quantity, … all have information about elevators, product purchasers and customers.

– For absolute certainty, consumers can ask people with technical or legal expertise to check and advise on the accuracy of product information.

From a legal and practical perspective, hopefully the article has suggested and answered some of the seemingly “new” things for readers. Every reader should always be a smart consumer to eliminate the risk of unsafe things.

In case of needing to consult, check and verify information about elevator products, consumers can contact Vietnam Elevator Association by phone number: 024 73099868, email: contact@vnea.com.vn or report to Elevator Magazine (hotline: 0989761499).