Green growth and sustainable development have become the national policy of many countries. One of the leading solutions is to save energy. In that trend, elevator manufacturers are constantly improving and applying high technology to reduce electricity consumption in their products.

Saving energy has become a national policy

Energy saving solutions have been invested in by many countries. In energy saving solutions, energy labeling is now commonly applied because it both requires manufacturers to comply with commitments on energy saving and reminds consumers of the use of energy saving products. There are already more than 120 countries with minimum energy efficiency regulations for equipment and requirement for energy label.

In Vietnam, energy conservation is an important content in the national energy policy. On March 9, 2017, the Prime Minister issued Decision No. 04/2017/QD-TTG stipulating the list of vehicles and equipment subject to energy labeling, the application of the minimum energy efficiency level and the roadmap perform. According to statistics from the Ministry of Industry and Trade, there are more than 20,000 types of products approved by enterprises.

Vietnam energy label

At the present time, most household electrical appliances such as air conditioners, refrigerators, washing machines and cars are operated by Energy Label. The types of devices that consume a lot of energy have been gradually phased out and are no longer produced. For example, in the past, CRT monitors were very popular, at that time, plasma and LCD screens were considered high-end products. However, only a while, after the introduction of led and oled screens, plasma and LCD screens have become “antique”. Therefore, approaching and forming a “green” mindset for the elevator industry is essential if you do not want to be left behind in the future.

Solutions for green growth and sustainable development

In the trend of green environmental protection and sustainable development, groups of solutions must be applied synchronously from the production, use and recovery-recycling stages of elevators.

Firstly, in terms of elevator design and manufacturing, in Europe, manufacturers have built a modern, humane and community-oriented development strategy. From the field of administration, production, service, … are all towards environmental protection standards. All stages from raw materials, production, transportation, use to the end of the product life cycle are considered for environmental impact and must meet green environmental standards. Among the European elevator manufacturers, Orona has become the first elevator brand in the world certified to comply with the Ecodesign ISO – 14006 standard (Environmental management systems – Guidelines for incorporating ecological design, which is an international standard that specifies guidelines to help organizations establish, document, implement, maintain, and continuously improve their ecodesign management as part of an ecodesign system)

Secondly, in terms of using and operating elevators, for a long time, manufacturers around the world have explored many energy-saving options for elevators but focused on two main groups of solutions for hardware and software that control elevator.

Korean ReGen SRU-4000 energy-saving controller

Accordingly, the hardware solution applies many technological advances to the equipment, components and materials constituting the elevator. Choosing a gearless traction machine is adopted by many manufacturers and now the use of this device has become common. Next, energy regeneration is another remarkable advancement in energy-efficient elevator technology. For example, Korea’s ReGen SRU-4000 energy-saving control device is very popular. It essentially transfers regenerative electricity from the motor into the building’s internal grid for reuse. Not only performing the function of energy regeneration, but this device also improves noise, andvibration and enhances comfort when using the elevator. Another solution is to reduce the weight to the extent that allows some of the moving components of the elevator such as the cabin, the traction cable, etc. to be compact, more efficient, and consume less energy.

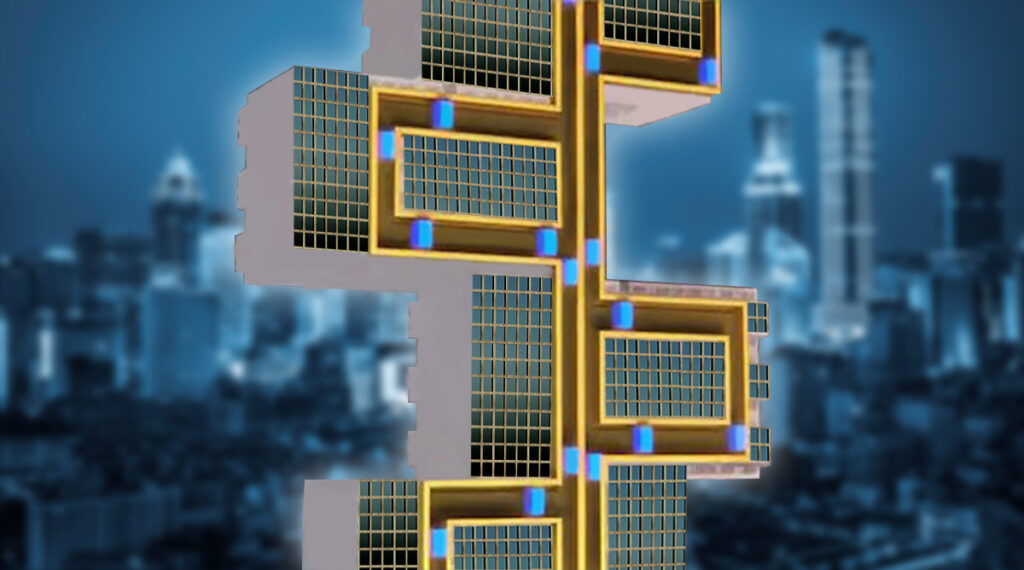

Recently, the magnetic elevator has been successfully tested, breaking all the traditional operating principles of the elevator. This technology allows multiple cabins to operate in one shaft. At the same time, instead of only moving vertically, the car of the magnetic elevator can move horizontally.

This system is calculated to save up to 60% compared to the conventional elevator system.

Operation model of magnetic elevator

Previously, manufacturers optimized the redesign of the motor and ancillary equipment to create a machine roomless elevator. Other parts of the elevator such as doors, lights, ventilation fans, safety devices, automatic controls, sensors, etc. can also be improved, applying new technology to save energy. These improvements help the elevator to consume significantly less energy.

In the group of software solutions, destination selection control software has been applied at many large projects in Vietnam. According to calculations, this software enhances the transportation capacity of the elevator system by 30%….

Third, the solution group is for the recovery and recycling of elevators. In this group of solutions, manufacturers must take into account when designing and manufacturing elevators. Designed so that the elevator is not soon obsolete, using environmentally friendly materials but still ensuring the requirements for safe operation and use. For example, glass, plastic, other materials that are difficult to decompose will have a long-term negative impact on the environment and the treatment of these materials is very expensive.

Improvement for development

Currently, elevators consume about 4% of the energy produced globally, equivalent to twice the total energy produced in a year by Russia and Japan combined. On average, each elevator consumes about 10% of a building’s electricity. This number also increases with the development of the construction industry.

With such a large amount of energy consumed, the issue of energy saving has become urgent. Elevator manufacturers are racing to improve step by step to reduce energy consumption while ensuring performance and safety in operation.

An energy-saving European elevator model

In the global energy-saving trend, green elevators are being pursued by the elevator industry in the past few years and will thrive in the future

Elevator businesses around the planet are working to build and develop new technologies and designs that are sustainable and consume less energy.

CEO of TK Elevator (India) Manish Mehan said that in 2022, the elevator industry will focus more on the technological and sustainability aspects of elevators. But the main focus will be on Green Elevators and improvements to reduce energy consumption.

It is known that currently, not many countries have applied Energy Label regulations for elevators. But with the development of technology, customers will certainly choose for themselves high-tech products that are closest to the environment and save energy. And the Energy Label is a feasible and appropriate measure. In addition, the optimal criteria to contribute to saving energy that are advised to consumers when buying elevators are choosing the right elevator motor capacity, choosing the lighting system for the elevator, and maintaining the safety of the elevato routine maintenance..

In Vietnam, elevators are not on the list of vehicles and equipment subject to energy labeling, and the minimum energy efficiency level is applied according to Decision No. 04/2017/QD-TTG of the Prime Minister. However, in the global energy saving trend, energy saving is also an important criterion for Vietnamese consumers to choose elevators.

In fact, any business with a modern, humane, sustainable development strategy, environmental protection and above all towards the benefit of the community will receive support from the majority of consumers. It is also an inevitable development strategy that businesses around the world are aiming for, a positive development trend, a “race” to protect the environment in which anyone who does not participate will be left behind, will be lost and eliminate.

Le Hung

Designer: Tran Trung