Large investment but low interest rate, high risk, strict requirements, uncertain output, monotonous products… are the difficulties that enterprises manufacturing elevator components and equipment must overcome. That is the confidant of the CEO of a company that dares to “risk” entering the field of supporting industry for the elevator industry.

Manufacturing elevator components: Venture capital!

Mr. Bui Manh Cuong, Director of Tan Lap Elevator – Mechanic Co., Ltd (Tan Lap Company) – a rare company producing elevator components uttered that when talking about investment in supporting elevator industries. According to him, all elevator components and equipment require extremely strict conditions, standards and regulations. To manufacture and check product quality, elevator components and equipment need very expensive specialized and synchronous equipment. Normally, at present, domestic manufacturers mainly produce replacement components, only a few components can break into the field of assembly for new products. Meanwhile, imported elevator components and equipment are rampant with a “matrix” of prices and types, making customers not know who to trust. With such fierce competition conditions, investing in the production of components and elevator equipment at the present time is considered very risky and risky. Investment capital is high with little return, potential risks are concerns that investment businesses do not want to take risks. Those are also some of the main reasons why very few Vietnamese enterprises invest in the field of manufacturing elevator components and equipment today.

Production of elevator pulleys at Tan Lap Company

Tan Lap company is said to be quite risky when it has switched to manufacturing elevator components for 3 years now and has achieved the first successes. But to get the initial results is an arduous process of learning and adapting. Originally a mechanical workshop, the company’s previous products were spare parts and equipment for iron and steel factories, steel furnaces, etc. In recent years, along with the development of the construction industry, demand has increased. Demand for elevators increased very high, while the market for spare parts, accessories and equipment was mostly imported. Realizing the potential for production development and grasping market demand, Tan Lap leaders have switched to a very new production field: manufacturing elevator components. Mr. Bui Manh Cuong, the company’s representative, said that in the first days of commencing production, the most difficult job was to learn the market, find customers who have needs to offer products and wait for a response. After a period of listening to feedback, investing and improving the production process to meet the requirements of customers, the company has its first customers. However, currently, customers have only ordered 3 main components from the company, which are passive pulleys, counterweights and guiding clogs, with a relatively modest consumption level.

Need a fair and transparent game

In fact, to achieve standards and regulations for elevator components is not difficult, but to meet customer requirements is difficult. The requirements of customers seem simple but very difficult to implement: Product quality must be better than Chinese goods, but the price must be cheaper, must supply products immediately when they need it. In addition, various types of elevator components and equipment are rampant on the market, good and bad are mixed, and the price changes cannot keep up, which also makes it difficult for genuine supporting industry production enterprises.

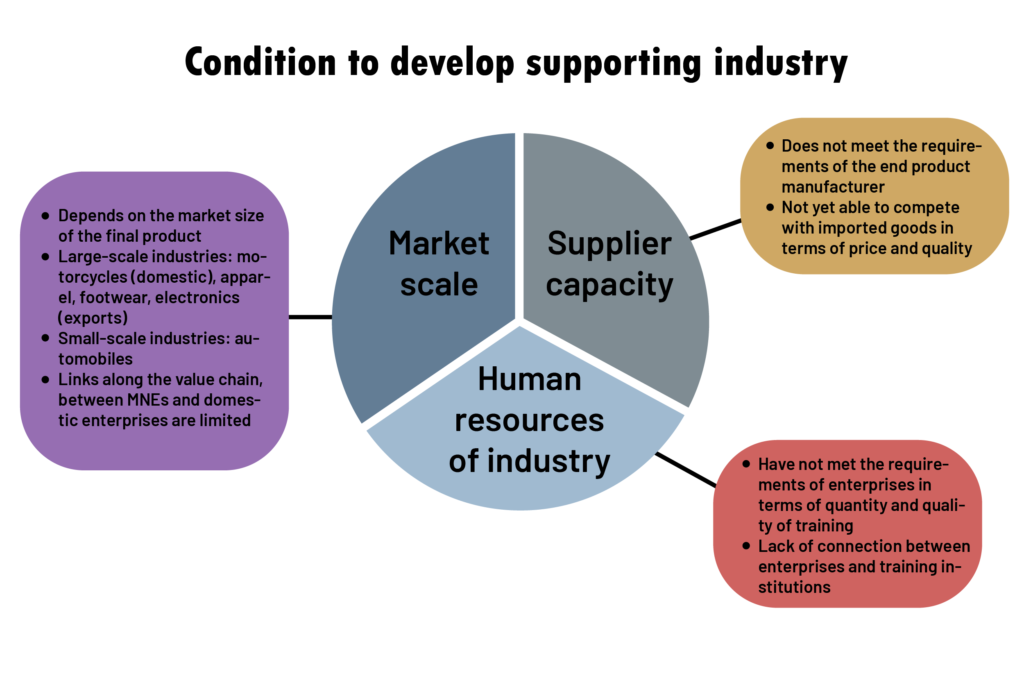

Supporting industries need conditions for development.

“Accepting the conditions set by the customer and the fierce competition in the market to join the game, we have overcome the initial difficulties. We can fully invest in expanding production, but we really need a fair and transparent competitive environment. Components and equipment imported or manufactured in the country must comply with standards and regulations, and be monitored in a transparent and equal manner. At the same time, we also want the support policies from the State to be closer and simpler to businesses, such as incentives for loans to import modern equipment to expand production, incentives for renting premises, factory,…” – Mr. Cuong said. These are the aspirations of many domestic enterprises that want to invest in the field of domestic elevator manufacturing and industrial enterprises supporting elevators.

According to statistics, every year, nearly 40,000 elevators are put into use in Vietnam, of which a large number of elevators are assembled in the country. In such a context, the potential of the elevator manufacturing supporting industry is huge. Some enterprises said they are willing to make large investments to import equipment, expand production scale, and transfer modern technology to serve the production of elevator supporting industries. But they also need a strong enough legal corridor to control quality, import tax, counterfeit goods, etc. for imported elevator components and equipment. Only then will there be a healthy competition, promoting domestic production to develop.

It is known that in order to promote the development of supporting industries, in addition to adding elevators to the list of domestically produced goods since 2014, the Government has issued Resolution 115/NQ-CP dated June 8th, 2014. 2020 on solutions to promote the development of supporting industries, including the supporting industry of the elevator industry. With such policies and solutions to promote development, it is hoped that the supporting industry, including the elevator industry, will have a strong and solid development environment, commensurate with its potential. Supporting industry development will be the driving force for enterprises to develop production and business in the country, proactively supply components and equipment, reduce dependence on importing raw materials, components and equipment from abroad, creating many jobs for workers. Along with that, it will limit trade deficit, limit foreign currency bleeding, towards the goal of exporting products, contributing to sustainable economic growth.