EM – Rather than relying on the principle of smoke venting through an opening at the top of the elevator shaft, design principles have shifted decisively toward implementing proactive measures to prevent smoke infiltration into the elevator shaft, thereby avoiding the upward spread of smoke to higher floors.

As outlined in Part 2: Airflow movement in the elevator shaft; Part 3: Heat, smoke, and elevator shaft ventilation, studies have shown that shaft ventilation openings are ineffective in releasing smoke during a fire, and may in fact exacerbate the spread of smoke and toxic gases to upper levels.

Smoke inhalation and exposure to toxic gases remain the leading causes of death in fires. Therefore, the primary objective must be to limit smoke migration into vertical shafts such as elevator hoistways and stairwells, thus minimizing the stack effect.

Variables in elevator shaft ventilation during fire events

Consider a room with a ceiling height of 10 feet (approximately 3 meters), in which a fully developed fire generates ceiling temperatures reaching up to 1,600°F (approximately 870°C). Such a fire produces immense heat, causing the air and smoke to expand and rise under strong buoyant forces.

These forces in a fully developed fire scenario are extremely powerful, far beyond the capacity of a passively ventilated elevator shaft to manage. Smoke can easily infiltrate the hoistway through gaps around the elevator doors, especially where no elevator lobby or smoke barrier is provided.

Illustration: Smoke rising through the elevator shaft but blocked at the top despite the presence of ventilation openings

Data provided by the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) identify leakage areas surrounding elevator doors, showing that a single elevator door may have a leakage area ranging from 0.34 to 0.72 ft² (approximately 0.03 – 0.067 m²).

For a hoistway serving four elevator cars, the total leakage area per floor can reach up to 2.9 ft² (approximately 0.27 m²). Gaps around elevator doors at the fire floor present an easy pathway for smoke to enter the shaft.

While top-mounted shaft vents may help release trapped smoke and air, the effectiveness of these vents depends on various factors: the vertical position of the fire relative to the shaft opening, the neutral pressure plane (where internal and external pressures are equal), and stack effect forces within the shaft.

More importantly, the cumulative leakage area around elevator doors across all floors tends to promote smoke movement via the stack effect, further reducing the effectiveness of top-venting mechanisms.

Thus, top-of-shaft ventilation represents merely a passive measure and has highly limited effectiveness in smoke control. Its success is subject to many uncontrollable variables and is often overpowered by stronger forces such as stack effect driven by hot smoke. Specifically, leakage around elevator doors at each floor can transform the shaft into a “giant chimney,” rendering the top vent ineffective or worse, accelerating smoke migration to upper floors.

Measures to Prevent Smoke Infiltration into Elevator Shafts

What, then, is the best strategy for ensuring safety during a building fire? The most effective approach is to prevent smoke from entering the elevator shaft.

A study by the U.S. National Institute of Standards and Technology (NIST) on smoke migration into elevator shafts identified two methods that significantly reduce risks:

– Enclosed elevator lobbies

– Temporary roll-down smoke barriers positioned directly in front of the elevator doors

Smoke curtain blocking smoke infiltration into the elevator shaft

Section 3006.3 of the current International Building Code (IBC) prescribes three options to protect elevator hoistways:

– Enclosed elevator lobbies, separated from adjacent spaces by fire partitions (in the absence of an automatic sprinkler system) or smoke partitions (if sprinklers are present);

– Additional door assemblies installed in front of the elevator landing doors – typically consisting of smoke curtains or temporary roll-down barriers that have been tested for smoke and draft control in accordance with UL 1784 (Standard for Air Leakage Tests of Door Assemblies). These curtains are deployed automatically upon activation of the building’s fire alarm and sprinkler systems;

– Or pressurization of the entire hoistway.

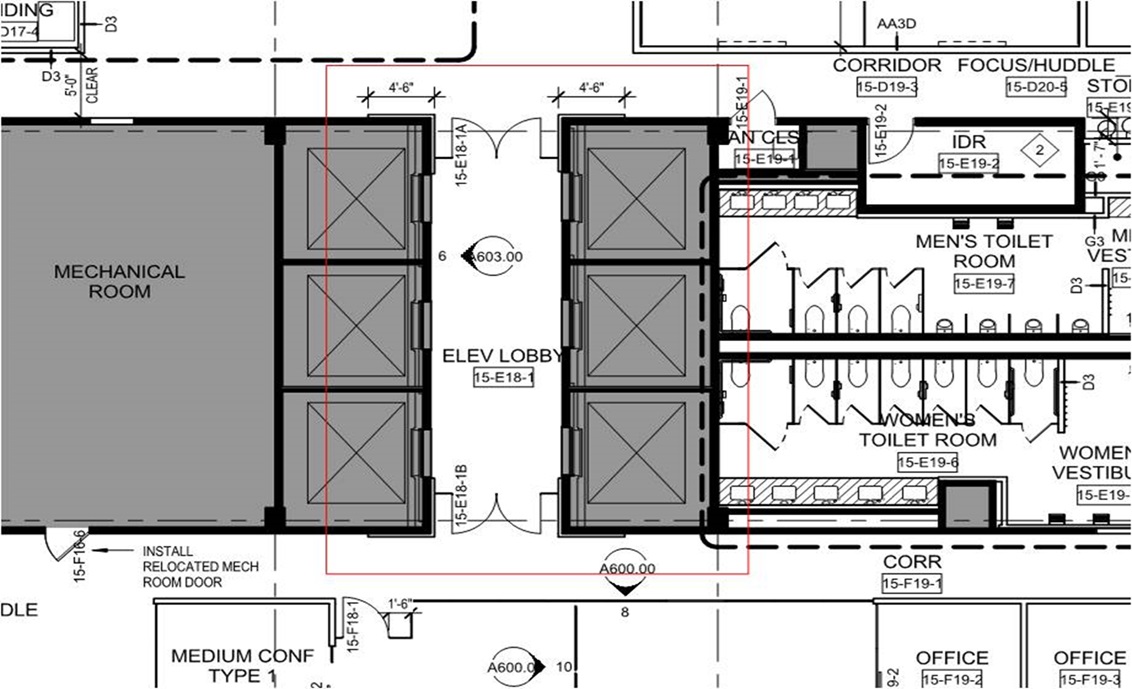

Diagram: Enclosed elevator lobby configuration

These protective measures significantly extend the survivability of trapped occupants. They also allow continued use of the elevator for firefighting and rescue operations by emergency personnel.

Previous NIST studies have also shown that the leakage area of elevator doors is a key factor in the movement of smoke into shafts and its subsequent spread to upper levels. Computational modeling tools were used to simulate airflow and air quality in a ten-story building.

The results demonstrated that reducing elevator door leakage could triple visibility on upper floors, regardless of whether the building was equipped with an automatic sprinkler system.