EM – Over time, technical studies, practical experience, and tragic incidents have demonstrated that elevator shaft vent openings do not deliver the intended effectiveness. On the contrary, they often pose critical life safety issues in the event of a fire.

As previously discussed in “Part 2: Airflow movement within the elevator shaft”, ventilating the elevator shaft accelerates the movement of convective airflow between the interior and exterior of the building, thereby intensifying the stack effect. This issue is critically important for controlling the spread of smoke and heat within the shaft during a fire.

Shaft vent openings were originally intended for smoke exhaust in fires

In addition to the reasons outlined in “Part 1: Why is there ventilation in the elevator shaft?”, this was the most important justification for the previous regulatory requirements. The primary purpose was to prevent the accumulation of smoke and heat within the elevator shaft during a fire.

Prior to 2015, the International Building Code (IBC) required elevator shafts to be equipped with vent openings. These vents had to be located at the top of the elevator shaft and either open directly to the outside or be ducted through non-combustible conduits with fire-resistance ratings equivalent to that of the shaft.

Under earlier approaches, it was believed that if smoke entered the elevator shaft, a vent at the top would facilitate its escape to the outside and prevent smoke from backflowing into other floors.

Specifically, U.S. building codes dating back to 1986 required elevator shaft vents in order to ensure that “in the event smoke enters the shaft, a vent opening at the top of the shaft is the simplest means to prevent its spread and to facilitate post-fire smoke extraction.”

However, research findings and hard-learned historical lessons have shown that ventilating the elevator shaft in an attempt to limit smoke spread is ineffective, and may even produce adverse effects.

Hazards posed by shaft ventilation

According to previous elevator standards and regulations, the total minimum vent area was required to be at least 1% of the cross-sectional area of the shaft. However, discussions surrounding this issue have consistently concluded that ventilating the elevator shaft in this manner is inappropriate. A vent area equal to 1% of the shaft cross-section is insufficient for either diluting or exhausting smoke from the shaft.

Initially, elevator shaft vents were passive openings with no control mechanism. Later, with growing requirements related to airtightness and building energy efficiency such as minimizing loss of conditioned air or heat from HVAC systems, shaft vents began to be equipped with mechanical dampers that automatically open in response to smoke detector signals.

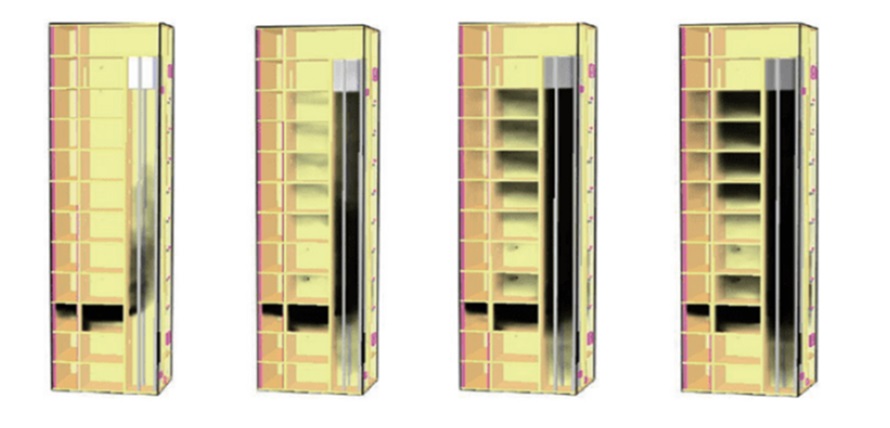

Simulation of smoke propagation to the top of the elevator shaft where vent openings are installed

Prior to 2015, Section 3004 of the International Building Code (IBC) stipulated that elevator shafts serving three or more floors must be equipped with vent openings of at least 3 square feet (approximately 0.28 m²), or 3.5% of the cross-sectional area of the shaft. The IBC also allowed for a reduction in this requirement if the building was equipped with an active mechanical ventilation system. Additionally, certain exceptions were applicable to buildings protected by an automatic sprinkler system.

Although these ventilation measures were considered valuable to some extent, the reality observed in several historically devastating fires in the United States has raised considerable doubts. In nearly all of these incidents, the fire originated on the ground floor, where elevator and stair shafts acted as vertical channels for the accumulation and upward spread of smoke, heat, and flames.

Much of this phenomenon was attributed to the stack effect, which was, in part, intensified by the very presence of elevator shaft vent openings.

Stack effect in fire scenarios, elevator shaft vented at the top

The stack effect is a natural aerodynamic phenomenon caused by pressure differentials within a building. It is most pronounced in very tall buildings (e.g., over 420 feet, or approximately 128 meters) and becomes significantly stronger during cold weather.

According to the laws of physics, any fluid (gas or liquid) will naturally flow from areas of higher pressure and temperature toward areas of lower pressure and temperature, as the fluid seeks to equalize these differences.

In the event of a fire, vent openings at the top of the shaft exacerbate the stack effect. Hot air and smoke are drawn upward more rapidly, accelerating the vertical spread of smoke to upper floors.

If the volume of smoke vented through the top opening is less than the amount of smoke entering the shaft, smoke accumulation will occur. A portion of the accumulated smoke near the top of the shaft may be forced back into the adjacent upper floors through door gaps and other leakage paths.

Simulation of smoke propagation in the elevator shaft

According to previous elevator standards and regulations, the total area of shaft ventilation openings was required to be at least 1% of the cross-sectional area of the elevator shaft. However, discussions surrounding this issue have consistently indicated that ventilation of elevator shafts is inappropriate. An opening area equivalent to 1% of the shaft’s cross-section is not considered sufficient to dilute or remove smoke from within the shaft.

Therefore, a review of major fire incidents in U.S. history that resulted in significant casualties, most of which originated on the ground floor or lower levels, reveals that the majority of fatalities occurred on upper floors, where victims succumbed to smoke inhalation rather than direct exposure to flames.

The issue of smoke migration is not limited to fires originating on the ground floor. Hot smoke and toxic gases from a fire – regardless of its point of origin – can infiltrate through small gaps around elevator doors and rapidly spread to upper floors.

Historical Fire Lessons in the United States

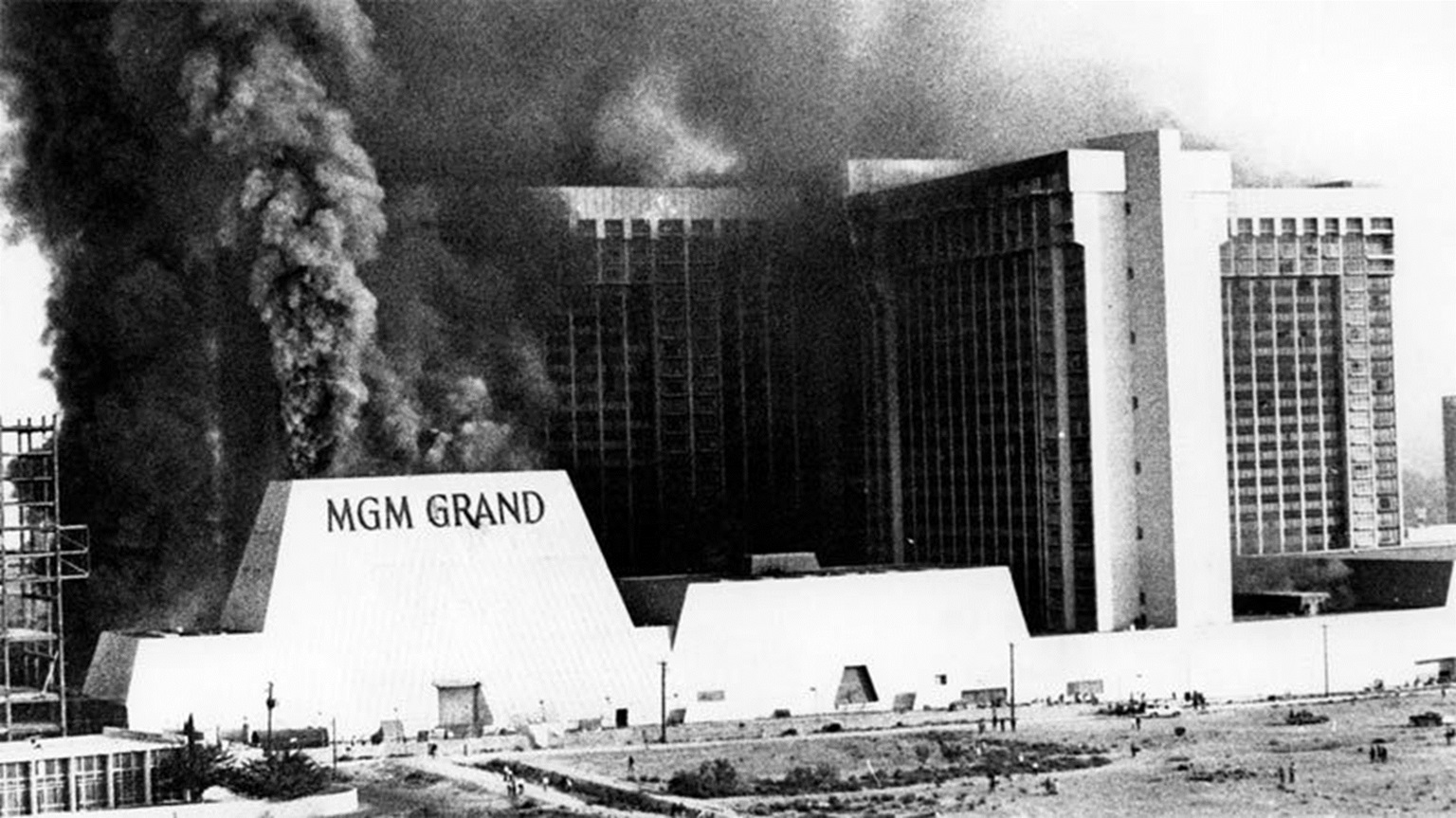

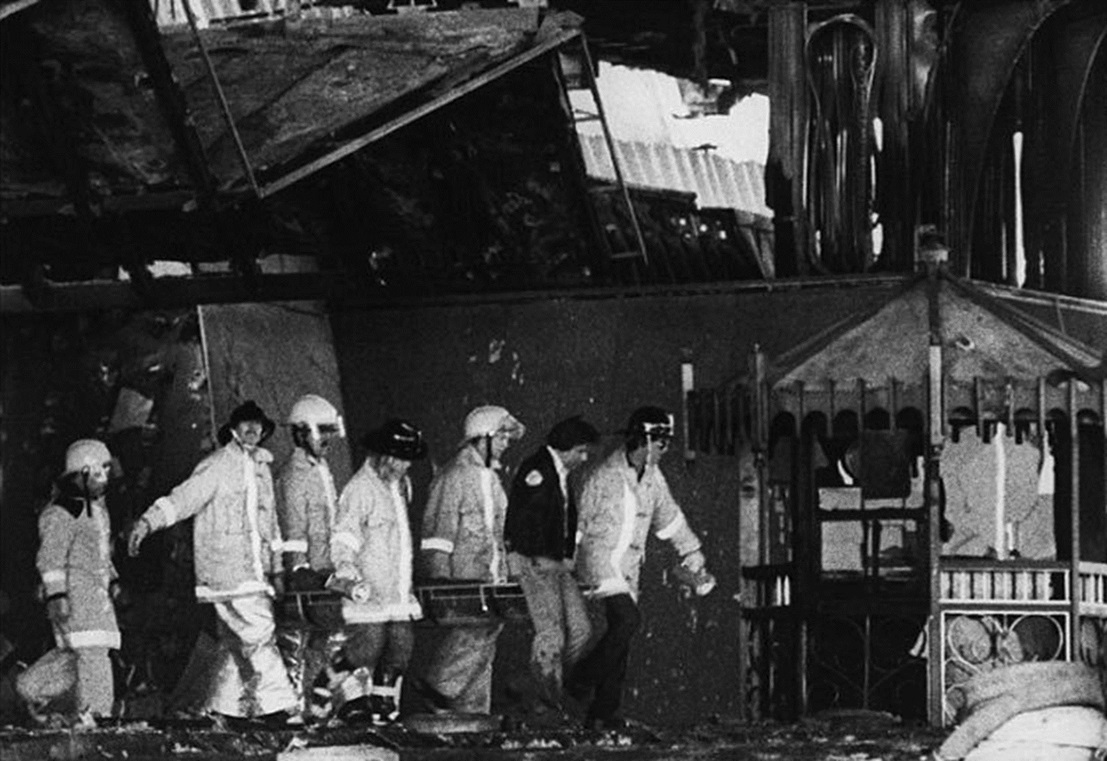

Notable incidents where elevator shaft ventilation aggravated fire scenarios include the Roosevelt Hotel fire (1963) in Jacksonville, Florida; the MGM Grand Hotel fire (1980) in Las Vegas; and the Retirement Center fire (1989) in Johnson City, Tennessee. At the time of these fires, the prevailing building codes in effect all required elevator shaft vent openings, consistent with the pre-2015 International Building Code (IBC).

A prominent example is the 1980 MGM Grand Hotel fire in Las Vegas. At the time of the fire, approximately 5,000 people were present in the hotel and casino. The fire originated in the casino area on the ground floor. Heat and smoke quickly spread through penetrations, elevator shafts, and stairwells, reaching as high as the 21st floor of the 26-story building.

As a result, most fatalities occurred between floors 20 and 25, with a total of 85 deaths, primarily due to smoke inhalation and carbon monoxide poisoning.

The MGM Grand engulfed in smoke and flames

To this day, it remains the deadliest fire in the history of Nevada and the third-worst hotel fire in modern U.S. history.

The MGM Grand fire also holds historical significance, as it marked the first instance in the United States where helicopters were used to evacuate nearly 300 people from the rooftop of a high-rise building. These individuals were forced to move upward due to the intense heat and smoke that spread rapidly throughout the hotel.

Therefore, the justification for using a top-mounted vent in the elevator shaft as a means of smoke exhaust during a fire event is not always valid. The effectiveness of elevator shaft ventilation in fire scenarios is subject to numerous variables, including outdoor temperature, stack effect, buoyant forces, external wind pressure on the building envelope, etc., as previously analyzed in “Stack effect and air convection phenomena” under “Part 2: Airflow movement within the elevator shaft”

Consequently, the traditional principle of smoke venting through the elevator shaft has gradually shifted toward a more robust and safety-oriented approach: preventing the spread of smoke and fire into the elevator shaft, as further elaborated in “Part 4: Controlling smoke migration into the elevator shaft”