EM – When ventilation openings are installed in the elevator shaft, they accelerate the movement of convective airflow between the interior and exterior of the building, thereby intensifying the stack effect and exerting a greater impact on the elevator’s operation.

As mentioned in “Part 1: Why is there ventilation in the elevator shaft?”, ventilation openings were once a mandatory requirement and had to be installed at the top of the shaft. Their purpose was to prevent excessive pressure during cabin ascent, control odors, and allow for smoke evacuation in the event of fire.

This article focuses on evaluating the movement of airflow within the elevator shaft. The airflow behavior in the elevator shaft will be assessed based on two primary effects: the piston effect caused by cabin movement and the stack effect resulting from thermal and convective airflow dynamics.

Elevator shaft ventilation from the perspective of reducing pressure buildup during cabin movement

In addition to addressing concerns related to odor control and the accumulation of gases and hazardous substances within the shaft, ventilation openings are also designed to account for pressure buildup caused by the piston effect during elevator cabin movement.

The British Standard BS 5655-6, updated in 2002 to replace the 1990 edition, explicitly states in Clause 5.3.3: “Note: Attention shall be paid to building and fire protection regulations, which may require the shaft to be ventilated.” “Special arrangements may be required where natural ventilation is inadequate due to the operation of the doors and the gaps around them, the access doors/covers, and other shaft openings such as ductwork.

The elevator shaft must not be used to provide ventilation for any rooms other than those serving elevator equipment. Where the shaft is ventilated via the machine room or pulley room, a ducted system must be installed to discharge air externally. Ventilation openings must be fitted with louvered grilles or other protective measures to prevent rain, snow, birds, and other elements from entering the shaft.

To mitigate cabin vibration caused by pressure fluctuations, for elevators operating at speeds exceeding 2.50 m/s, pressure relief ventilation openings may be necessary. A single elevator may require a minimum vent area of 0.3 m², with an additional 0.1 m² for each additional elevator sharing the same shaft.”

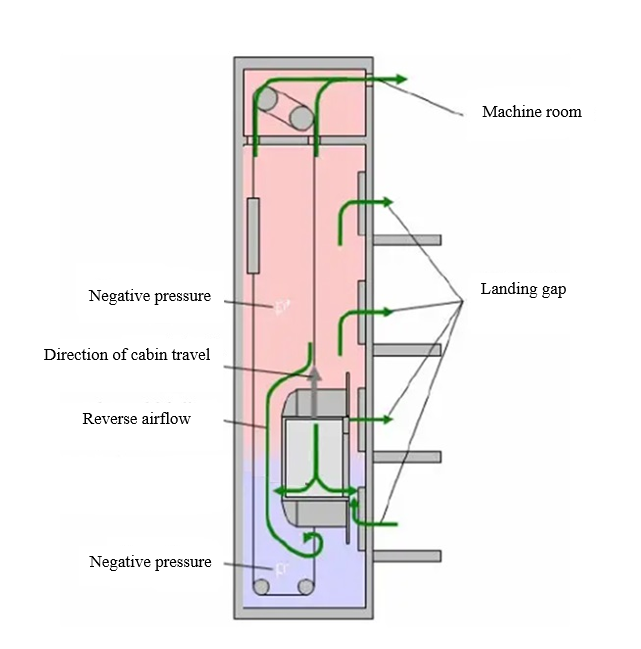

Nevertheless, research has shown that the pressure generated by elevator cabin movement within the shaft – referred to as the piston effect – is relatively minor. A descending cabin pushes the air beneath it upward through the shaft.

In addition, air leakage through landing door gaps and cable holes at the top of the shaft (in machine room-type elevators) can be significant. According to data published by the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), for buildings with a typical floor height of 3 meters, a single elevator door may have air leakage areas ranging from 0.34 to 0.72 ft² (approximately 0.03 to 0.067 m²).

Air Leakage Points and Airflow Direction When the Cabin Ascends

Similarly, the current standard EN 81-20 stipulates that: When landing doors and car doors are closed, the clearances between door panels, or between the panels and the vertical stiles, transoms, or sills, shall not exceed 6 mm.

Moreover, the piston effect varies depending on the number of cabins within the shaft and the shaft’s cross-sectional area. For example, in a single-cabin shaft operating at a speed of 400 feet per minute (fpm) (approximately 2.03 m/s), the pressure differential is only 0.08 inches of water column (in. H₂O), or about 20 pascals (Pa).

In a shaft with two elevator cabins operating at the same speed (400 fpm), the pressure differential reduces further to 0.02 in. H₂O (approximately 5 Pa). Even at a higher speed of 700 fpm (approximately 3.56 m/s) in a dual-cabin shaft, the pressure differential only reaches 0.05 in. H₂O (about 12.5 Pa).

Stack effect and air convection phenomena

As previously analyzed, the piston effect caused by cabin movement within the shaft is relatively negligible. In practice, buoyant forces (natural upward forces caused by temperature differentials) have a significantly greater impact on airflow within the elevator shaft compared to the minor pressure changes resulting from elevator movement.

*Buoyant forces: These are upward forces exerted by a fluid (liquid or gas) on an object submerged in it. In this context, it refers to the upward movement of warmer air due to temperature-induced density differences.

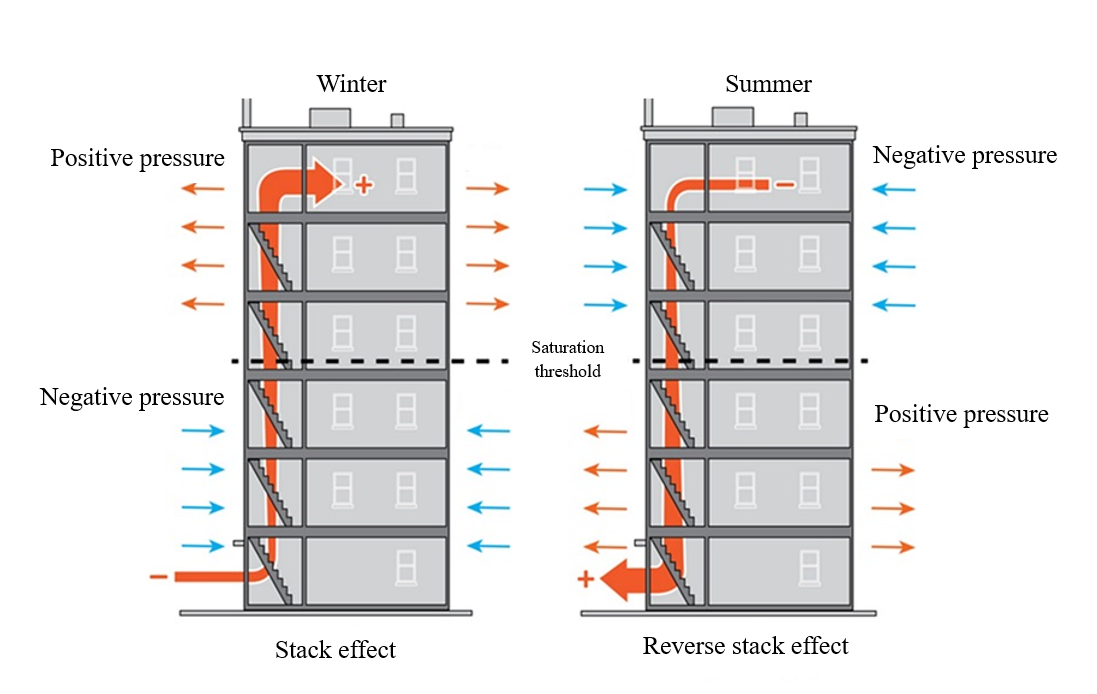

In tall buildings during cold weather, the temperature difference between the warm indoor air and the cold outdoor air creates a natural upward airflow – air convection. This drives warm air to rise vertically through building shafts (e.g., elevator shafts, stairwells), effectively turning them into giant chimneys—a phenomenon known as the stack effect.

*According to fundamental physical principles, when a gas (such as air) is heated, its molecules move faster and spread further apart, making the gas less dense and lighter than an equivalent volume of cold air. A simple analogy: a hot-air balloon rises because hot air is lighter than cold air.

*In addition to the temperature differential, another contributing factor to the stack effect is the infiltration of outdoor air into the building through open or unsealed areas such as parking garages, entrance lobbies, etc.

For high-rise buildings located in hot climate zones, where the interior is cooled by air conditioning systems, a natural downward airflow may develop within the vertical shafts of the building. This downward movement of air is referred to as the reverse stack effect.

At this point, the cooler and denser indoor air being heavier than the warmer outdoor air tends to sink and escape through the lower levels of the building, thereby generating a downward airflow.

Description of the temperature differential between the interior and exterior of a building, which causes both the stack effect and the reverse stack effect (right)

According to data published by ASHRAE, pressure differentials resulting from the stack effect—whether normal or reverse can range from 0.07 inch H₂O (approximately 17 Pa) at a height of 30 ft (approximately 9.1 m) to 0.7 inch H₂O (approximately 174 Pa) at a height of 300 ft (approximately 91.4 m). In addition, a 15 mph (approximately 24 km/h) wind blowing perpendicular to the building can generate a wind-induced pressure differential from the windward to the leeward side of approximately 0.12 inch H₂O (about 30 Pa).

When the elevator hoistway is ventilated, both the stack effect and the convective airflow into the shaft become more pronounced. This results in greater air pressure differentials, which may impact elevator performance such as increased vibration, noise levels, etc.

For instance, high-speed airflow entering the elevator shaft through vents, door gaps, or as a result of door operations, combined with elevator cars moving in opposite directions can cause significant turbulence, leading to instability during car travel.

Additionally, due to air convection, cold air enters the building through access points such as corridors, parking garages, and basements. Within the hoistway, wind exerts pressure against the gaps between landing door panels, resulting in increased door closing resistance. This phenomenon is most noticeable at the uppermost and lowermost floors, where pressure differentials are the greatest.

The intensification of the stack effect inside the elevator shaft not only affects elevator operation and passenger comfort, but also presents further challenges related to the spread of heat and smoke within the shaft – topics that will be addressed in “Part 3: Heat, smoke, and elevator shaft ventilation”

In the event of a building fire, when smoke enters the hoistway and the shaft is ventilated at the top, the high temperature of the smoke will amplify the stack effect. Conversely, under reverse stack conditions (when the interior of the building or shaft is cooler than the outside), the presence of smoke in the shaft will reduce the reverse stack effect.