EM- Elevator doors, more than just an entrance, are also a safety barrier for users.

Carlo Ferrari

Corporate Marketing Communication Manager, Wittur

The structure of the elevator, since the intuition of Elisha Otis to build safety devices into it, has always been designed to guarantee the utmost safety to its passengers.

The concept of safety has evolved tremendously in the past 170 years since Otis demonstration in 1854. Several rules and regulations have come into effect to guarantee passengers’ and technicians’ safety in every aspect of the elevator operations.

The latest EN81-20/50 has further increased the safety level by introducing new tests to ascertain the capability of elevator components to provide adequate safety performance in case of malfunction of the elevator.

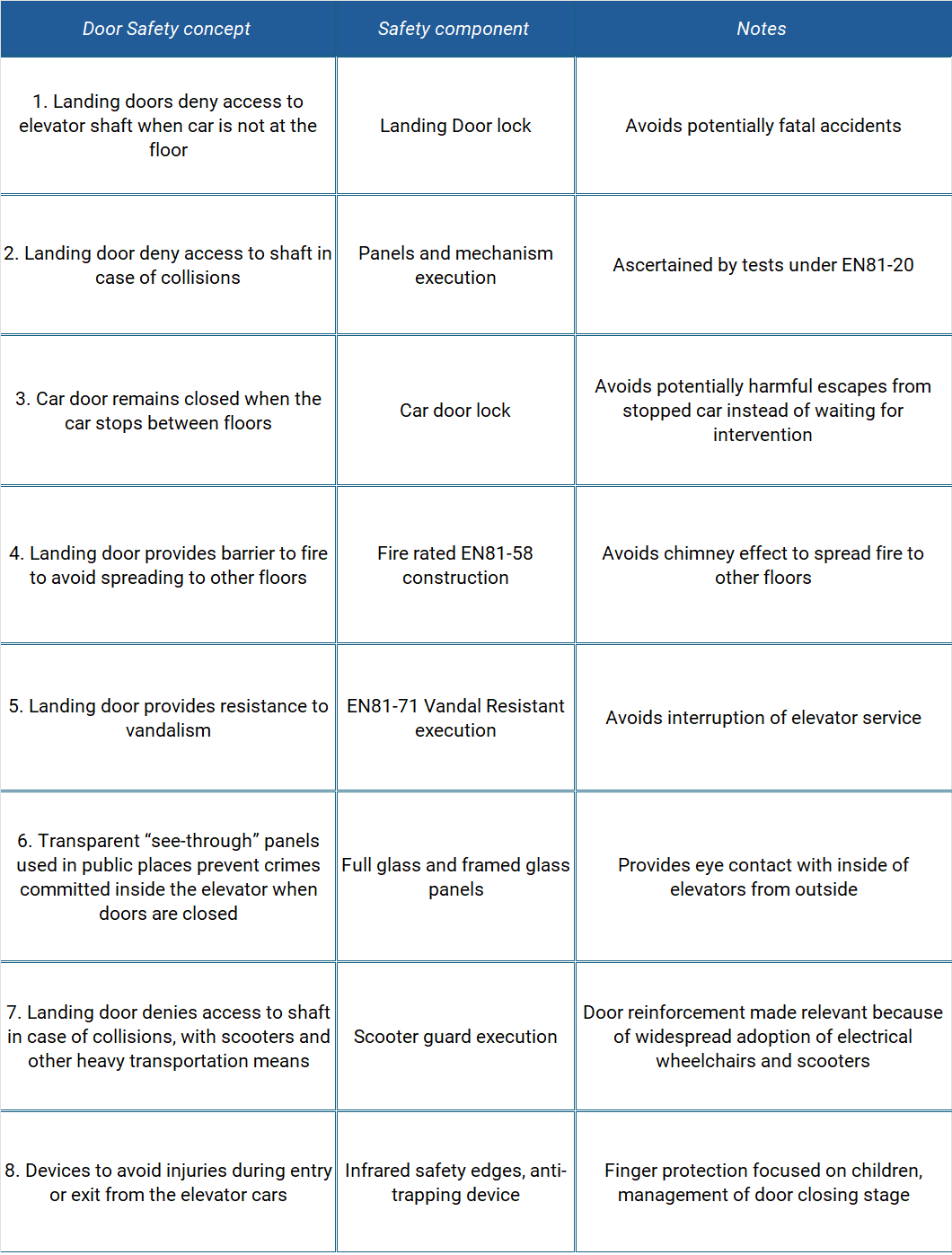

Although most people tend to think about overspeed governors and safety gears when talking about elevator safety, in fact doors are a key element of the safety chain of any elevator (see table below).

Doors provide different kinds of elevator safety

Doors provide different kinds of elevator safety

1. Landing doors deny access to elevator shaft when car is not at the floor

The first and most evident safety concept provided by elevator doors is the capability of landing doors to deny access to the elevator shaft if the elevator car is not at the floor. The very design of modern elevator doors is based on the concept that the car door must level to the floor and only then the landing door lock can be opened by the car door using a mechanical lever, and the landing door panels can be moved.

2. Landing doors deny access to shaft in case of collisions

EN81-20 requires test to landing door to make sure they can withstand collisions and still block access to elevator shaft. A first test is performed on closed doors, and it consists of applying a force of 300 N on different locations of the door panels. After applying that, results should be:

– No permanent deformation of panels greater than 1 mm

– Elastic deformation: less than 15 mm

– The safety function of the door must not be changed as a result of the thrust.

A second test is performed with a force of 1000 N, and as a result:

– Landing and car doors must withstand a thrust of 1000 N with a maximum deformation of 10 mm, without changing their functionality and safety.

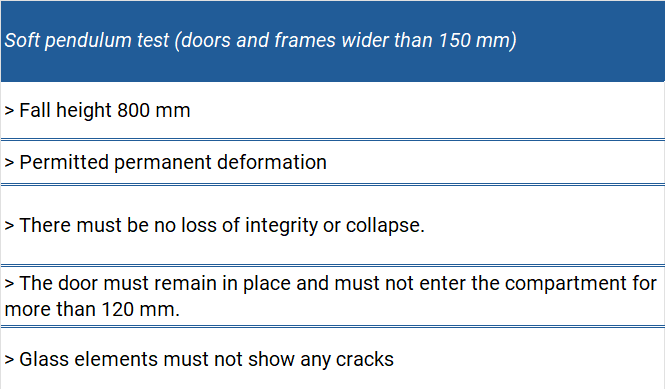

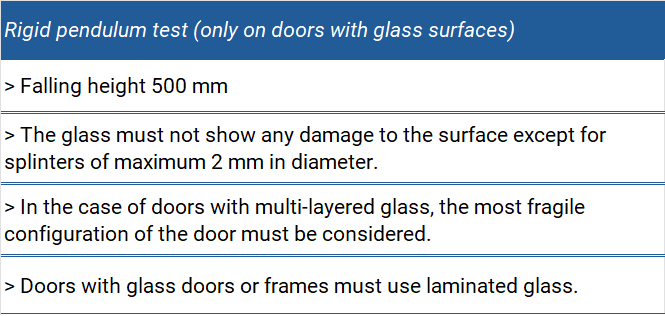

Furthermore, a test with a pendulum is always performed on elevator doors and it is required for certification.

Requirements for pendulum tests for standard panels

Requirements for pendulum tests for standard panels

Requirements for pendulum tests for glass and framed glass panels

A modern automatic door test centre

3. Car door remains closed when the car stops between floors

The car door lock is now compulsory on new elevator installations. It makes sure that it is not possible to force the car door opening from the elevator car. This is also a possible source of accidents, as in case of elevator stopping between floors, there is a tendency to try to escape by forcing the doors. This is very dangerous and is rightfully made impossible by the car door lock device.

The car door lock being a safety device, it has its own conformity examination certificate, which is integral part of the required certifications for elevator commissioning.

Conformity examination Certificate for Car door lock

4. Landing doors provides barrier to fire to avoid spreading to other floors

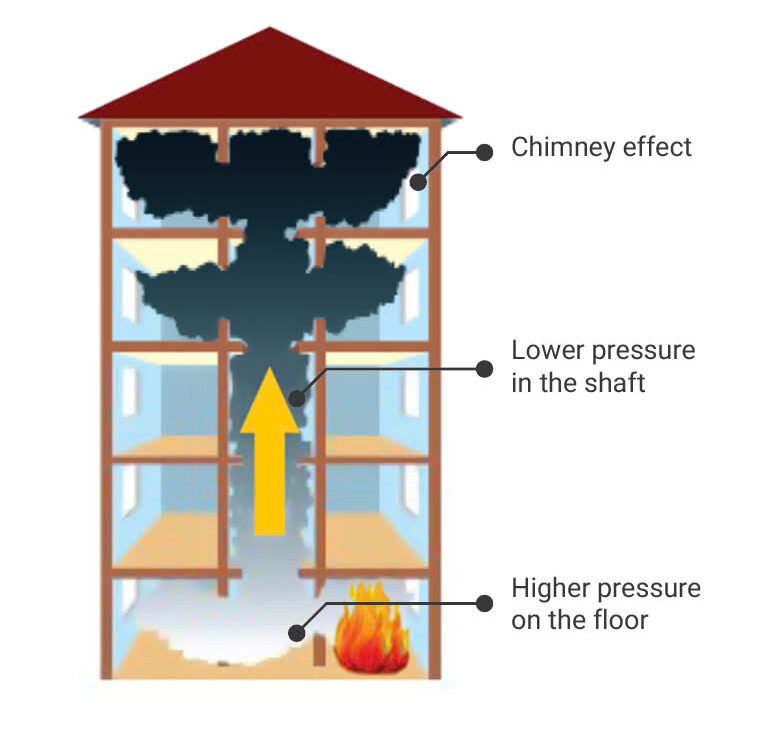

Fire is a major threat for multi-level buildings. To avoid spreading of fire to several floors, most modern buildings are designed with compartmentation concepts.

Compartmentation concept

Fire entering the elevator shaft can spread to upper and lower floors. Fire resistance of Landing doors is crucial to enforce compartmentation of elevator shaft and avoid fire propagation in the building: the fire must overcome two landing doors until it finds combustible material again as it is very unlikely to have fire ignition in the shaft (no combustible material).

The role of Fire-Resistant Elevator Landing Doors according to EN 81-58 is to prevent fire, smoke and gas leakage to enter the well and to be transferred to another floor.

Fire resistance of landing doors is particularly important due to chimney effect:

– Pressure differential due to openings at the top of elevator shafts

– Temperature differences between elevator shaft and building rooms

This means that higher hot gas leakage rates could occur in an elevator shaft than between rooms at the same floor.

Chimney effect in the elevator shaft.

The introduction of EN 81-58 norms, and importance given to hot gas leakage has led to a design change for elevator landing doors: fire-resistant landing door use labyrinths to reduce leakage of gas to a minimum and to avoid transmission of flames through the closed landing door. Special materials applied to the panels can be used to avoid also heat transfer.

Only through R&D expertise and extensive testing it is possible to obtain a suitable design for a substantial reduction of gas leakage and for the door to keep its function of blocking access to the shaft also in case of fire.

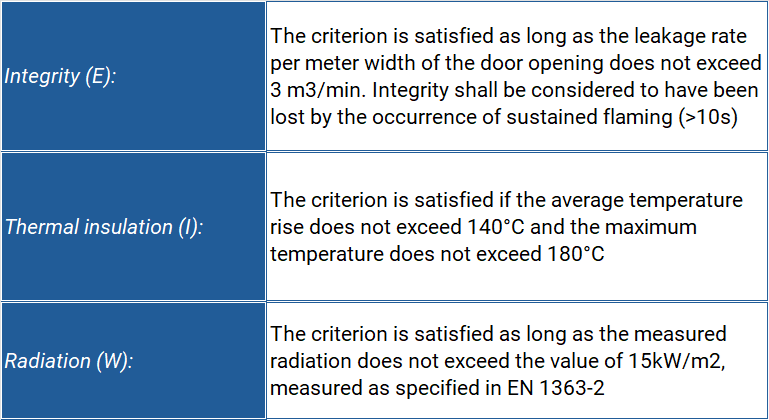

Performance of door is tested in qualified certifications laboratories following strict procedures. In particular:

– Evaluation of leakage rate made with tracing gas system equipment

– Unexposed face temperature measured with 5 thermocouples per each door leaf

– Temperature of door frame measured with min. 2 thermocouples

– Heat radiation measured from the unexposed face as per EN 1363-2

– More than 10 seconds of continuous flaming on unexposed side is considered as loss of Integrity (E).

Essential Fire Resistance Criteria according to EN 81-58

Fire resistance test on elevator door with framed glass panels

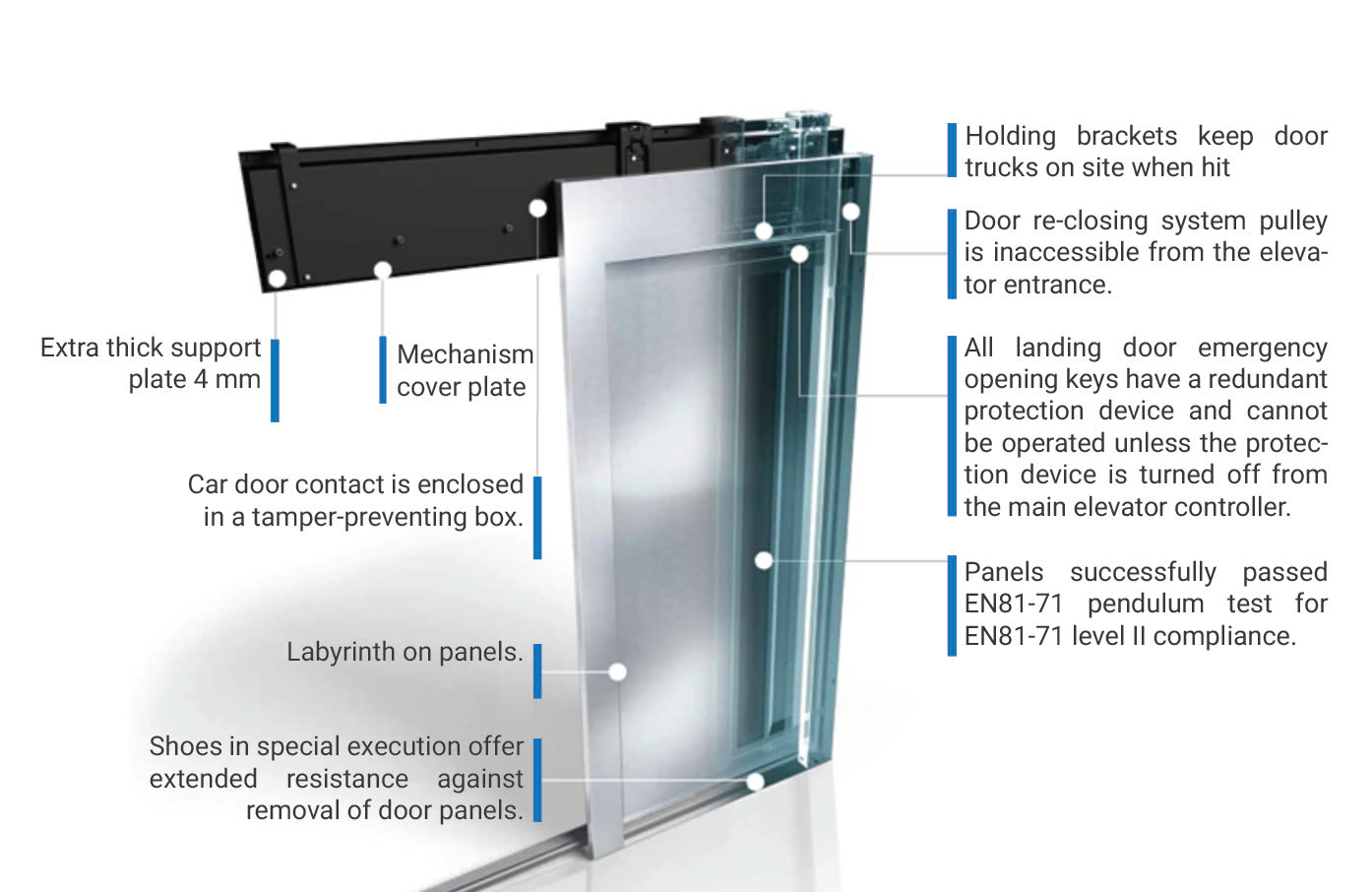

5. Landing door provides resistance to vandalism

In residential multi-storey buildings, it is important to obtain the highest availability of the elevator system. In some urban areas, to avoid potential callbacks due to vandalism, specific features of the elevator doors are implemented to make the door resistant to most act of vandalism (see table below). This is also important to avoid potential failures of the elevator after a vandalism has been performed, and to guarantee the safety of passengers.

Key elevator door vandal resistant execution features.

6. Transparent “see-through” panels used in public places prevent crimes committed inside the elevator when doors are closed

This topic is not strictly connected to mechanical failures of the elevator; it is about creating safe spaces for public areas, where elevators are installed. In case of metro and railways station open at night it is important to avoid having spaces where crime can be committed unseen.

Most areas in public spaces are now monitored by CCTV; however, the use of full glass and framed glass panels for elevator doors has a great potential to prevent possible crimes.

Example of framed glass elevator doors installation in a railway station.

7. Landing door denies access to shaft in case of collisions, with scooters and other heavy transportation means

The widespread availability of battery powered transportation aids for injured, physically impaired and elderly people has pushed the development of specific door designs to resist accidental collision and preserve the door functionalities.

These specific designs are tested to maintain the integrity of the door panels in case of impacts made by a typical scooter, wheelchair or similar vehicles during normal use conditions.

Collision-proof features on landing door

8. Devices to avoid injuries during entry or exit from the elevator cars

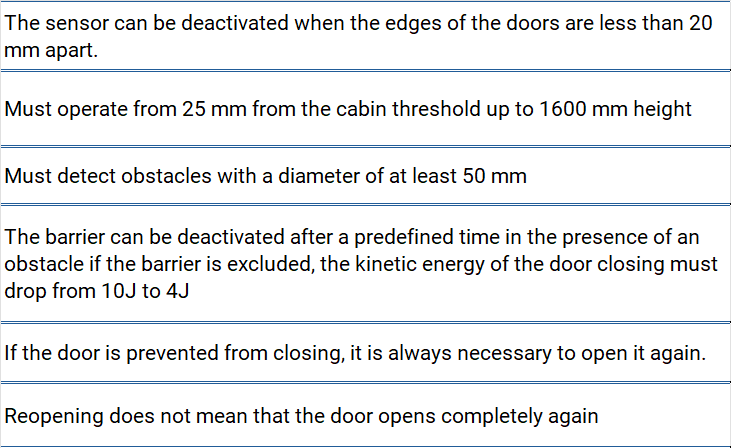

The new EN81-20 rule has introduced new requirements for infrared sensors placed on elevator doors, which are now always required for new elevator installations. Those sensors can detect any object while doors are closing, and they trigger a closing movement stop and the re-opening of the doors to avoid any potential injury to a passenger.

Requirements of infrared sensors according to EN81-20

In case of panoramic doors, EN81-71 requires to install a device that detects the presence of fingers up to a height of 1.60 m from the threshold and stops the movement of the door in the direction of opening. This device can be of mechanical type; more recently, new optical finger trapping prevention devices have been introduced on the market.

This solution is based on a contactless optical device installed on each door panel, managed by the elevator controller through an electric connection box. The optical concept is very effective when installed in panoramic elevators with framed glass doors in public places: children are more likely to be attracted to the glass panels when the elevator is moving, and optical based finger trapping device very fast reaction times prevent any hand injury during door opening.

Conclusions

The evolution of norms has substantially increased the safety level of elevators; in particular, elevator doors have been extensively redesigned to reach higher safety performances in many circumstances.

Surely the next norms evolution will further improve the status, although today elevators are already by far the safest transportation means on earth.

Carlo Ferrari

Corporate Marketing Communication Manager, Wittur

Founded in 1968, Wittur is one of the world’s leading independent elevator components manufacturers with an extensive global manufacturing footprint and sales network and a broad range of products. Its product offering features a large range of components for new elevator manufacturing and sourcing, for spare parts and for modernization and upgrades.

With over 600 worldwide patents, of which 126 unique patents, components made by Wittur span from sophisticated mechatronic components for car and landing elevator doors to other critical components such as gearless drives, slings, safety gears and cars.

As of 2023, the Wittur Group has achieved significant milestones, owning a network of 13 product sites and 7 global technology centers. With a widespread presence in over 50 countries and a workforce of more than 4,700 employees, Wittur has solidified its position in the vertical transportation industry, achieving an impressive revenue of 865 million Euros.