For high-rise buildings, traction technology is the only option because it meets the following criteria: long travel, high speed, high frequency of use, etc… However, for homelift, it is not that easy. The experts of the Vietnam Institute of Lift Engineering Application give some useful advice when choosing a home lift.

Lift is a second group of commodity product (group of products, goods in conditions of transportation, storage, preservation, reasonable and proper use, still potentially harmful to people, animals, plants, properties, environment). Therefore, we should choose the lift that meet the safety standards. Especially, for homelift, this is paramount.

Standards that needs to be followed include:

– Standards on design

– Standards on production and testing

– Standards on installation, conditions for putting into use

– Standards on maintenance.

Regarding lift regulations, readers can read more details at: Overview of lift regulations

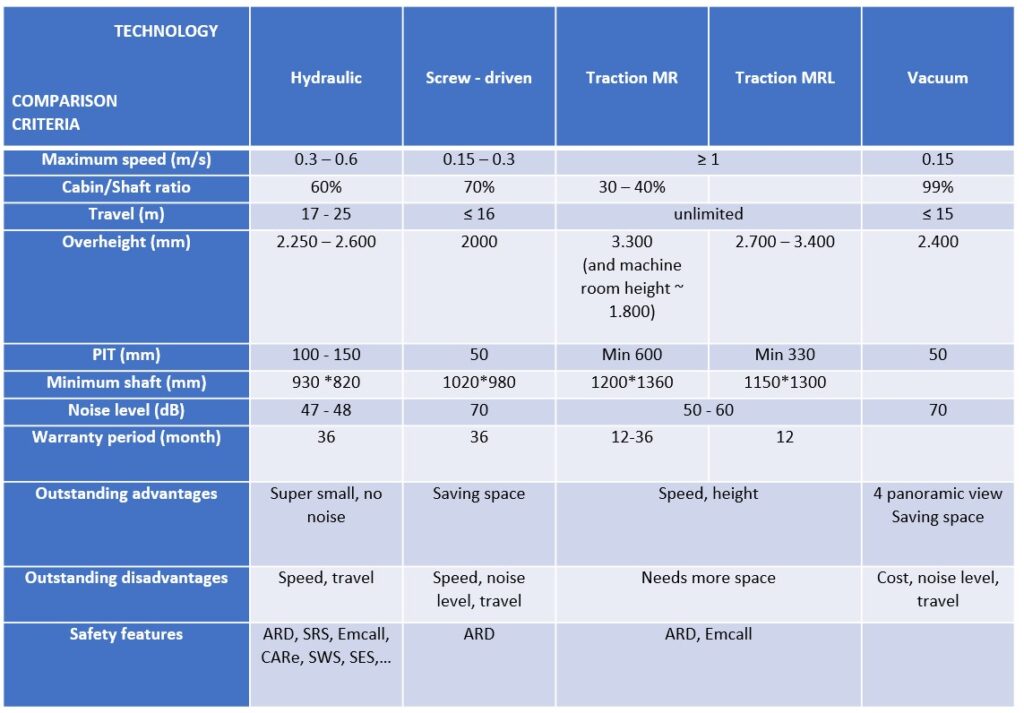

There are four types of drive technology on the market today with the following characteristics:

*Note:

Traction MR (Machine Room): Traction lift with machine room.

Traction MRL (Machine Roomless): Traction lift without machine room

Thus: Depending on the needs, actual terrain, techniques, etc., lift users can choose the type of lift with a suitable design for their home.

According to experience with lift products, the lifespan of lifts also has certain differences. For hydraulic lifts, mechanical wear during operation takes place the least. According to statistics, the durability of lifts according to each type of technology is as follows:

– Hydraulic lift: Over 15 years

– Traction lift: Over 10 years

– Screw–driven lift: Over 10 years

– Vacuum lift: Over 5 years

However, the durability of the lift is also greatly influenced by the process of use and maintenance. If used correctly, it can last much longer than the estimated life, or vice versa.

Maintenance during the use of the lift play an important role in increasing the durability of the lift

Choosing a lift product supplier should be based on the service delivery capacity of that business. Criteria needs to be noted are:

– Seniority capacity, field capacity: The seniority in the market of an business can show the reputation of the business. In addition, because the lift is a product related to safety, the operation process may contain many risks of unusual incidents, so when choosing a service and product supplier, it is also necessary to pay attention to the field capacity of business. The field capacity can be assessed through the office network (the ability to shorten the time to the site), the time committed to being present to handle the incident, etc.

– Financial capacity: An enterprise with clear financial capacity affirms the quality of development in the market, has a higher reputation and can accompany you in the process of using lift products in the future, because for the lift to have a long service life, it is necessary to ensure good and stable service.

– Partner capacity: The reputation of the supplier, manufacturer, etc. as the partners of the lift supplier is also an important factor. You certainly don’t want to find yourself in a situation where you buy an lift product, but a few years later the original equipment manufacturer went bankrupt and the business that provided you with the lift product or service could not find the source for replacing components.

– Actual capacity: Actual inspection of lift products and works that the enterprise has provided in reality to verify the information on installation, warranty and maintenance that the enterprise mentioned in the capacity profile, avoiding cases of “virtual” capacity, not meeting commitments with customers.

Similar to other electrical equipment such as cars that need periodic maintenance, fuel costs, etc., the use of the lift is also costly in terms of: electricity, maintenance, etc,… Especially the maintenance and repair costs because this is a mandatory regulation of the State for this item. Specifically, the maximum time between maintenance sessions is 3 months (according to QCVN 32:2018/BLDTBXH), however, to ensure stable and safe operation, the recommended time is once a month.

Therefore, users also need to search and choose an lift supplier with lift service that ensures quality as well as reasonable cost. “Suitable” here does not mean cheap because of course the price is associated with quality, anyway this is a product with specific characteristics related to technical safety, so a reputable service provider, quality should still be the priority.

Users also need to search and choose a lift supplier with lift service that ensures quality as well as reasonable cost.

Because public lifts always have supervisors, just an emergency chimb and an interphone are enough to notify security guards when something goes wrong. In contrast, in case of home lifts, we must ensure that the elderly and children alone use the lift at home, so there should be some minimum organic characteristics such as:

– ARD: Automatic Rescue Device. This rescue unit operates in the event of a power failure, the automatic rescue device will use the backup power to bring the elevator to the nearest floor so that the user can exit.

– SRS: Self Rescue System. This feature works when there is a power failure, the ARD fails, you just need to press the red button on the screen, lift will automatically move to the nearest floor and open the door for users to step out outside. This feature helps you feel secure and proactive in situations that occur when traveling by lift.

– Emcall: Emergency call. This system works as follows: When something goes wrong, users just need to press the yellow button on the control panel, the lift will automatically make calls to 5 preset phone numbers in sequence (the number of the technician and family member) until the phone is connected. In addition, Emcall system also reports errors to the control center, helping technicians understand the situation, detect and handle errors in a timely manner. This can be considered as the 3rd level of rescue in the lift, preventing tragic incidents and preventing passengers from panicking when locked inside the lift.

– SWS: Stroke Warning System automatically activates when someone trapped in the cabin loses consciousness (stroke, fainting, ..). SWS will send a message to service center for timely rescue. This feature is useful in case the user loses consciousness and cannot perform any action to escape or call for help. Thus, the lift plays the role of a supervisor, proactively detecting and promptly notifying to support users.

– FDS: Flood detection system. This system works on the following principle: When there is water leakage or the customer forgets to lock the water valve, causing water to overflow into the lift, the FDS system will alert the customer by phone message. At the same time, the cabin from the lower floor will automatically move to a higher floor to avoid flooding, causing electric shock, electric leakage.

7. Investment cost

Regarding the investment cost to buy product initially, the traction lift costs from 250 million with domestically manufactured and assembled products (electronic components, traction machine, guide rails, etc., made in China; cabin made in Vietnam), for imported products, the price is from 600 million or more. For screw driven lift and hydraulic lifts, they can’t be manufactured in Vietnam yet but still have to be imported from abroad, along with vacuum lift costing from about 1 billion or more, depending on the height, number of stops, capacity, etc.

However, this is the basic cost for a lift, if there are investments in aesthetic design, special technologies, etc., it can increase investment costs.

Conclusion: Each type of lift has its own strengths and weaknesses. Depending on each specific case, consumers can choose the type of lift that suits the actual needs of their family and consult with lift experts.

Luu Hien Minh